Flexible packing former for concrete face rockfill dam face

A technology of concrete panels and flexible fillers, which is applied in water conservancy projects, marine engineering, construction and other directions, can solve the problems of unsatisfactory compaction quality, low compaction efficiency of flexible fillers, and insufficient artificial compaction strength. Beautiful appearance, easy bending and fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

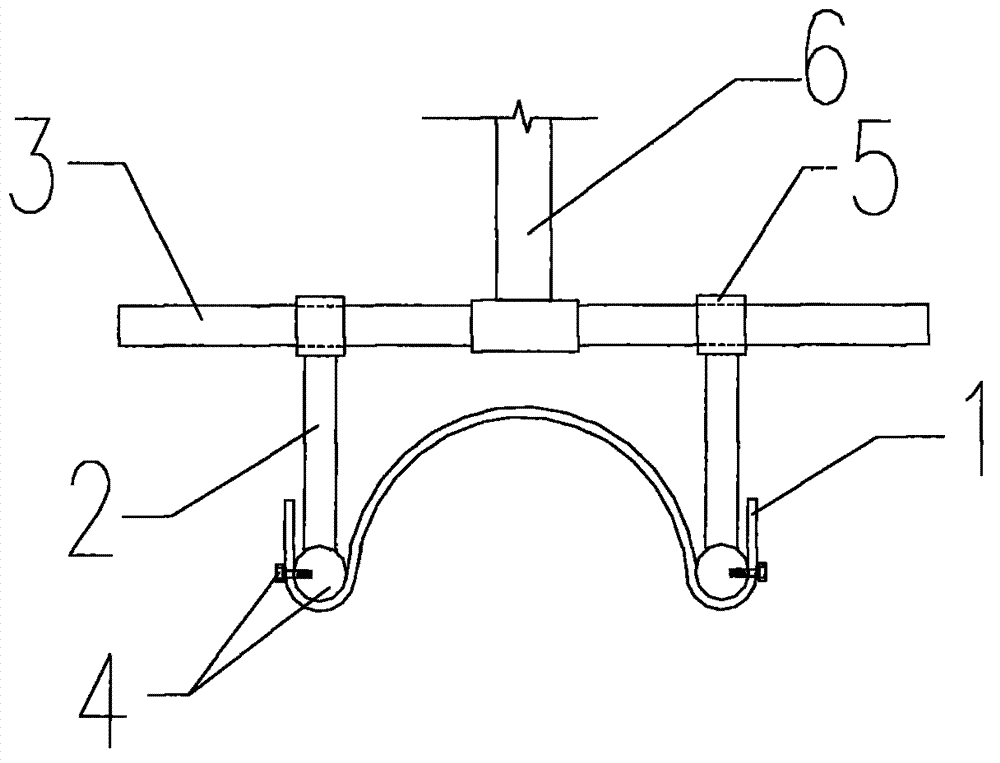

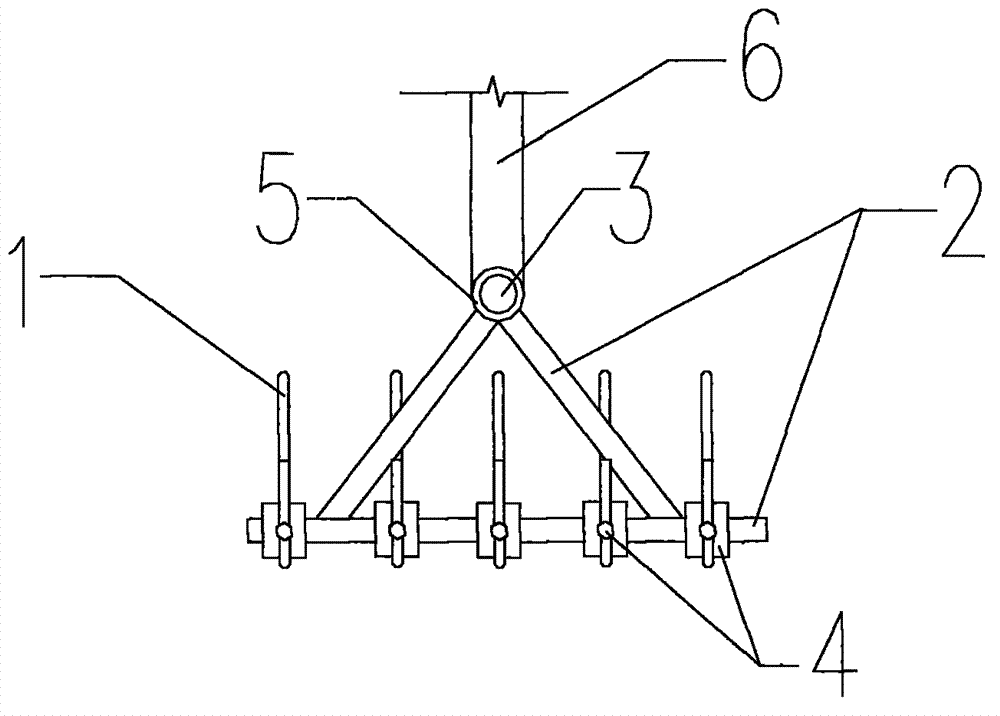

[0021] Such as figure 1 Schematic diagram of the front elevation of the flexible packing former and figure 2 As shown in the schematic diagram of the side elevation of the flexible packing former, the forming belt 1 is fixed on the fixing part 2 through the fixture 4, and the fixing part 2 is connected with the connecting part 3 through the bearing 5. By loosening the fixture 4, the length of the forming belt 1 in the fixture 2 can be precisely adjusted, and by adjusting the position of the bearing 5 on the connector 3, the distance between the fixtures 2 at both ends can be precisely adjusted, and various clamps can be precisely formed. The shape of the groove surface of the flexible filler can realize the multi-slit type and even multi-project general use of a set of formers.

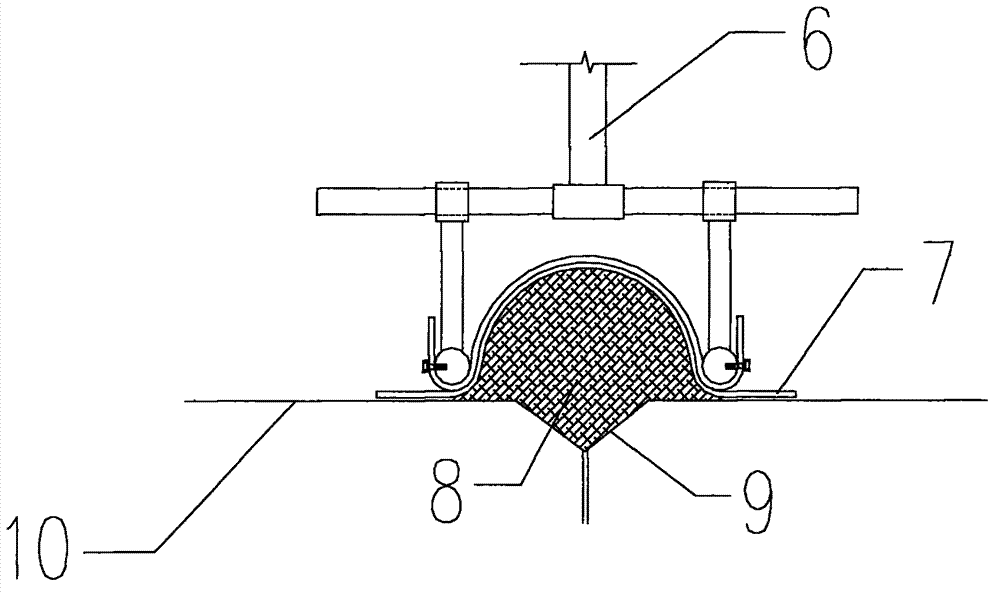

[0022] The construction diagram of the flexible packing former is shown in image 3 , the flexible filler molding device is located just above the V-shaped groove 9 on the surface of the concrete p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com