In-situ heat conductivity coefficient testing device and method for gas hydrate

A gas hydrate and thermal conductivity technology, applied in the field of gas hydrate thermal conductivity in-situ testing devices, can solve the problems of difficult hydrate samples and high hardness, and achieve the effects of smooth surface, dense interior, and accurate and reliable test values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

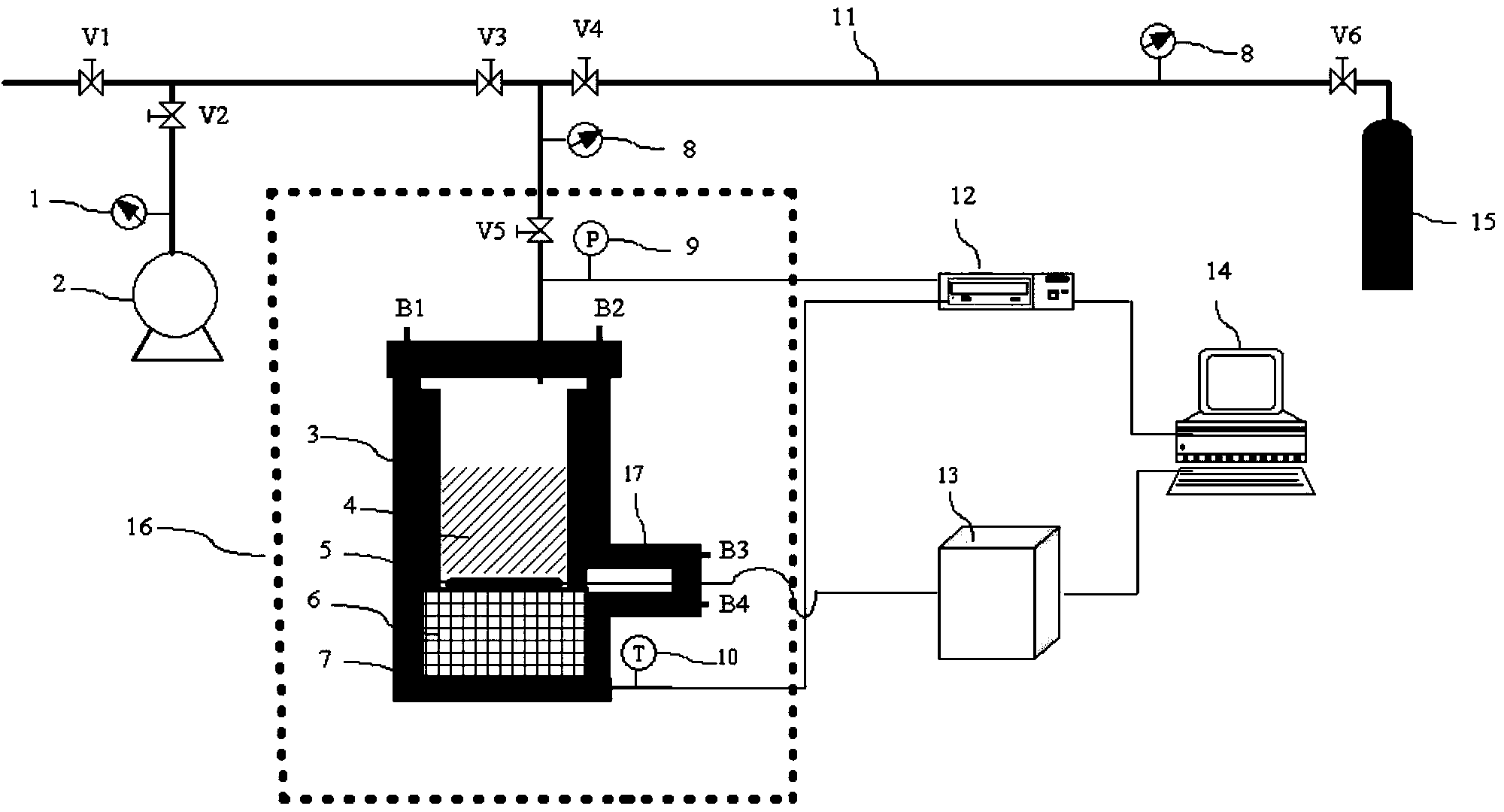

[0028] Such as figure 1 As shown, an in-situ test device for thermal conductivity of gas hydrates includes a temperature-controllable and sealable reactor 7, a thermophysical property analysis tester 13, a data acquisition instrument 12, and a computer workstation 14. The bottom of the reactor 7 is Filled with a background material layer 6, the inner wall of the reactor 7 above the background material layer 6 is provided with a fluoroplastic layer 3, and the input end of the thermal physical property analysis tester 13 is a heat conduction probe 5, and the heat conduction probe 5 is set on the The opening on the side of the reaction kettle 7 extends into the reaction kettle 7, and is adhered to the upper surface of the background material layer 6 by structural glue, and the background material layer 6 is made of the same material as the structural glue, and also includes a The temperature sensor 10 at the bottom of the reaction kettle 7, and the inflating system that is charge...

example 1

[0052] Using carbon dioxide and distilled water as experimental materials, the invention is used to synthesize carbon dioxide hydrate samples and test thermal conductivity.

[0053] First open the reactor 7, clean the reactor 7, add 25ml of distilled water after drying, and cover the reactor 7. Thereafter, the reaction kettle 7 and pipeline air are blown away by charging and releasing high-pressure carbon dioxide gas several times. Close valves V1 and V2, keep other valves unblocked, let the reactor 7 be filled with high-pressure carbon dioxide gas slowly for about 5 minutes, when the pressure in the reactor 7 exceeds 3MPa, close the valve V6, open the valve V1 to release the gas in the reactor Carbon dioxide gas, when the pressure is close to 2-3atm, quickly close the valve V1; so repeatedly, the reaction kettle 7 is charged and released with high-pressure carbon dioxide gas, repeated 3-4 times. Reactor 7 air intake afterwards, when pressure reaches 3MPa, close reactor 7, le...

example 2

[0055] Taking tetrahydrofuran and distilled water as experimental materials, the invention is used to synthesize a tetrahydrofuran hydrate sample and test its thermal conductivity.

[0056] Take distilled water and heat it to boil for 30 minutes, remove the air dissolved in the distilled water, and prepare a 23% THF aqueous solution after cooling. Close the valves V1, V4 and V6, turn on the vacuum pump 2 to evacuate the reaction kettle 7 and the pipeline, and close the valve V5 after the vacuum is exhausted. Open the air bath 16 to cool down the reactor 7. The temperature of the air bath 16 is set at 4° C., and when the temperature of the reaction kettle 7 drops to about 4° C., it is maintained for 2 hours. Thereafter, the set temperature of the air bath 16 was lowered by 0.5° C. every hour. When the pressure reading in the kettle basically does not change, it can be considered that the hydrate reaction is basically over. Let stand for 3 days and let the hydrate age for 3 d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com