Cu-rich nanocluster reinforced ultra-high strength ferrite steel and manufacturing method thereof

A nano-cluster, ultra-high-strength technology, applied in the field of ultra-high-strength ferritic steel strengthened by Cu-rich nano-clusters and its manufacturing, can solve the problem of limited strengthening effect of Cu particles, large spacing between precipitated particles, and uneven particle distribution. problems, to achieve the effects of excellent welding performance and plastic toughness, large production size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

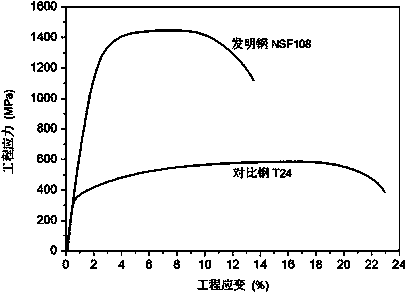

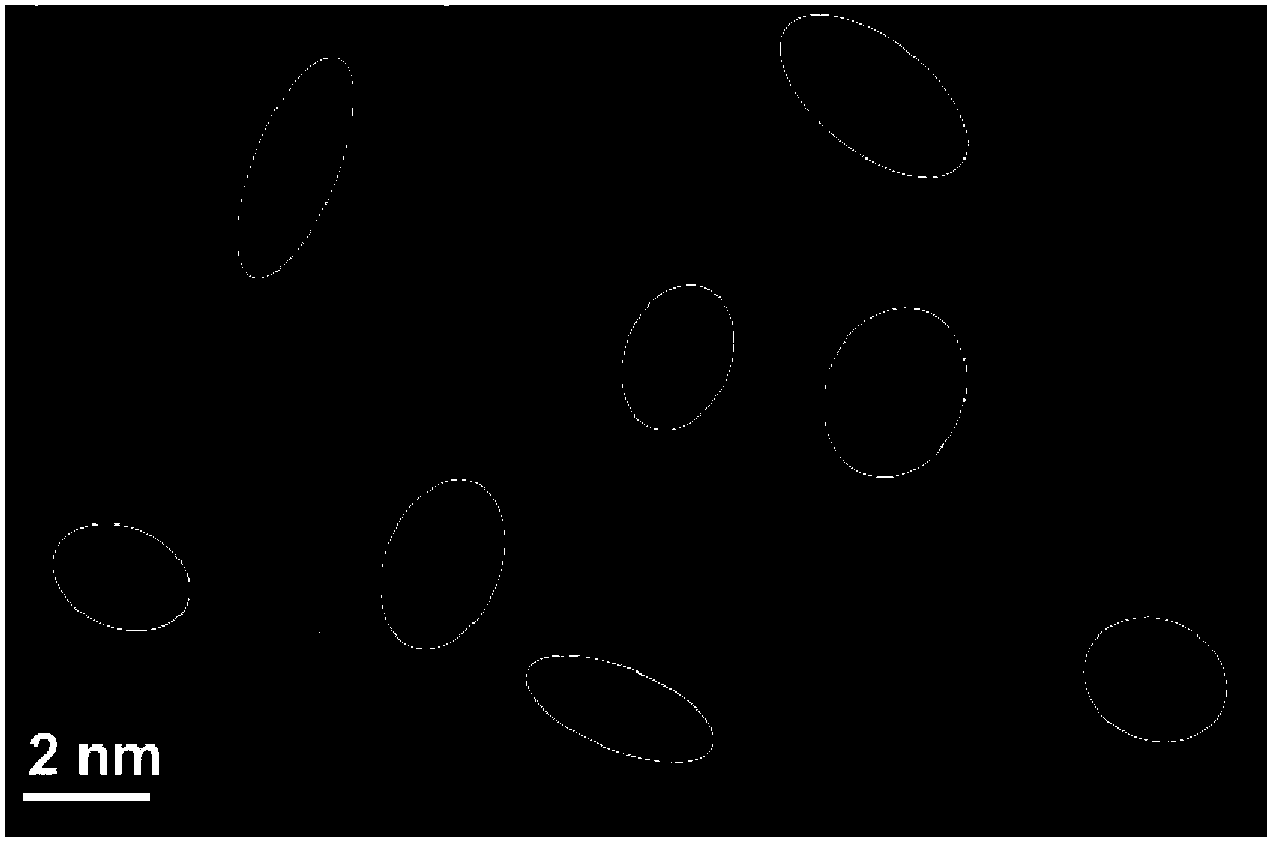

[0059] According to the composition range of the Cu-rich nano-cluster strengthened ultra-high strength ferritic steel of the present invention, nine kinds of inventive steel NSF101-109 were smelted, and T24 steel used in power stations was smelted at the same time for comparison. According to the alloy composition of NSF101-109 and T24 shown in Table 1, smelting and casting are carried out in an electric arc melting furnace, and the obtained ingot is rolled at a reduction of 5-10% each time to obtain the total deformation The amount is about 70% of the plate. The rolled plate was solution treated at 900°C for 0.5 hours, then cooled to room temperature by argon quenching, then aged at 550°C for 2 hours, and then cooled to room temperature by argon quenching , thus making the invention steel NSF101-109 and the comparison steel T24.

[0060] Table 1. Alloy composition of inventive steel NSF101-109 and comparative steel T24

[0061]

Embodiment 2

[0063] According to the alloy composition of NSF104 in Table 1, it is smelted and cast in an electric arc melting furnace, and the obtained ingot is rolled at a reduction of 5-10% each time, and the total deformation is about 70%. of plates. The rolled plate was subjected to solution treatment at 850° C. for 0.5 hour, then cooled to room temperature by water quenching, then aged at 550° C. for 2 hours, and then cooled to room temperature by air cooling. Invention steel NSF104' was thus produced.

Embodiment 3

[0065] According to the alloy composition of NSF104 in Table 1, it is smelted and cast in an electric arc melting furnace, and the obtained ingot is rolled at a reduction of 5-10% each time, and the total deformation is about 70%. of plates. The rolled plate was subjected to solution treatment at 1200° C. for 0.5 hour, then cooled to room temperature by water quenching, then aged at 550° C. for 2 hours, and then cooled to room temperature by air cooling. Thereby the invention steel NSF104″ was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com