Overlaying-combining-remanufacturing substrate material for Cr4 and Cr5 series of hot rolling work rolls and back-up rolls

A technology of working rolls and backup rolls, which is applied in the direction of welding/cutting media/materials, manufacturing tools, welding media, etc., can solve the problems of micro cracks and layered tearing off of the original roll and surfacing materials, and achieve improved crack resistance Diffusion ability, no surfacing defects, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 Preparation of primer material

[0067] (1) The composition of Cr4 and Cr5 series hot-rolled work rolls and back-up rolls for composite remanufacturing primer materials 1 and 2 are shown in Table 2:

[0068] Table 2 Mass percentage of deposited metal (wt%)

[0069]

[0070] (2) The preparation process of materials 1 and 2 is as follows:

[0071] A. According to the ratio shown in Table 2, the powder of each component is mixed uniformly in the powder mixer;

[0072] B. Slitting the cold-rolled steel strip into a 12-16mm wide steel strip with a slitting machine, rolling the steel strip into a U-shaped cross-section on the wire rolling machine, and filling the mixed U-shaped groove of the steel strip Primer material powder, and then roll the U-shaped steel strip into a Φ3-5mm welding wire blank tube;

[0073] C. Use a multi-connected linear wire drawing machine to draw the welding wire blank tube to the finished product size Φ2.4~4.0mm, and then use a la...

Embodiment 2

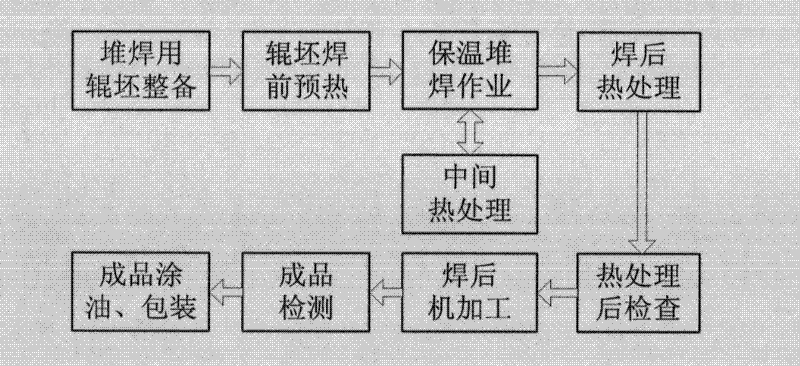

[0074] Example 2 Surfacing repair and performance test of support roller

[0075] (1) Support roller surfacing repair

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com