Reinforcing bar splice with threaded collars

a technology of reinforcement bar and threaded collar, which is applied in the direction of couplings, manufacturing tools, mechanical equipment, etc., can solve the problems that none is ideal for all situations, and achieve the effect of reducing thread stress concentration and preventing fatigue cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

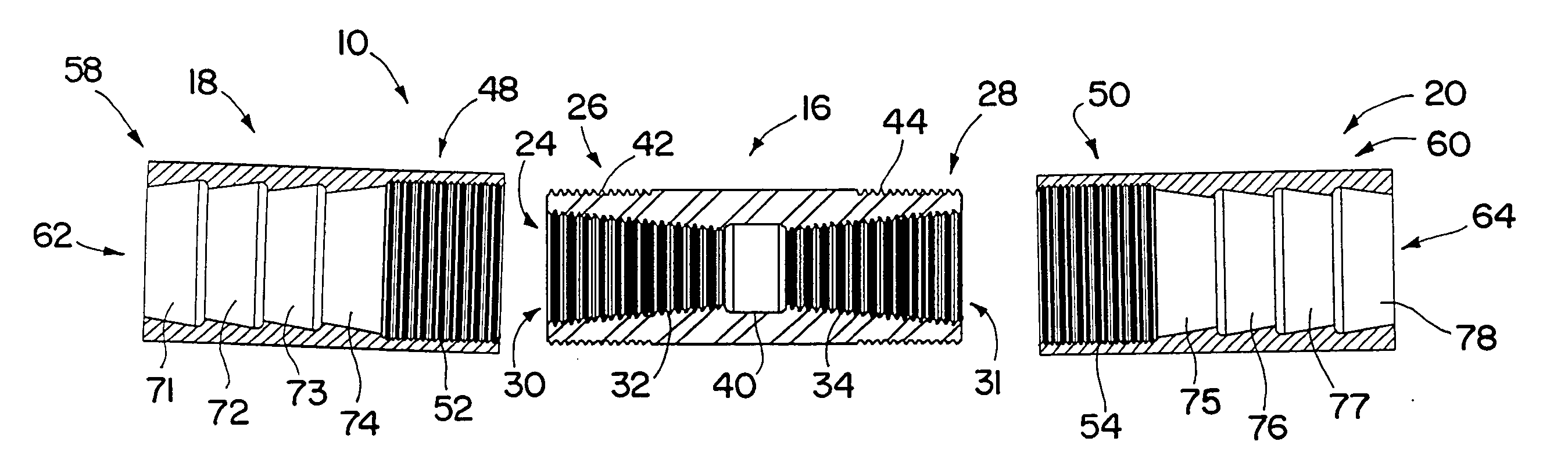

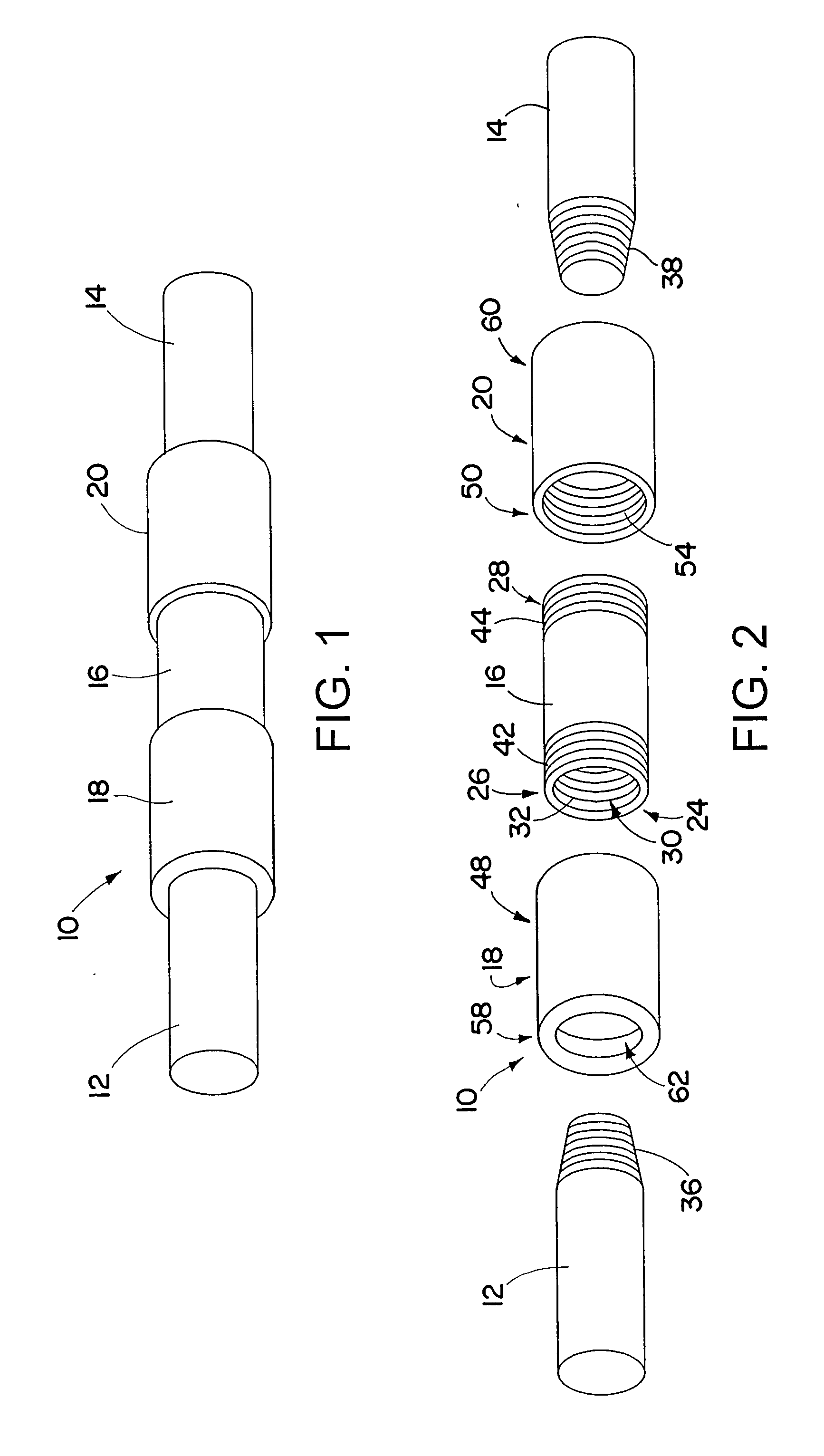

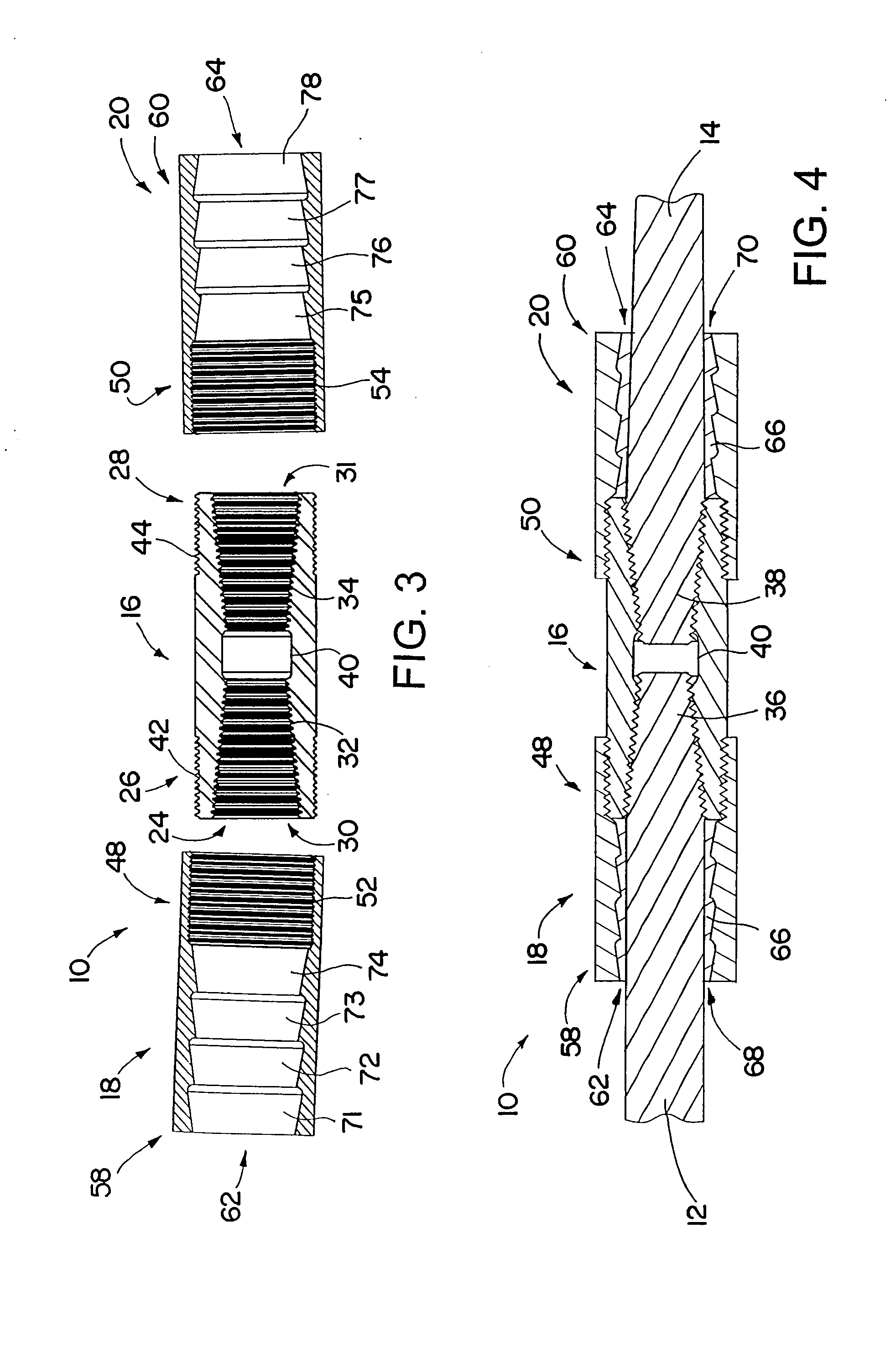

[0022]A reinforcing bar splice secures together reinforcing bar ends by utilizing, at both ends, both tapered-thread coupling and coupling involving a filler, such as a grout or an epoxy. The splice may include a central tapered-thread central sleeve or coupler, and a pair of collars that are screwed onto externally-threaded ends of the central sleeve. The central sleeve has a channel therethrough with tapered internal threads at both ends, and a center internal relief. The internal relief is an increased radius center portion that ensures full thread contact between the tapered internal threads and external threaded sections of the rebar ends. The sleeve has externally-threaded ends that are engaged by internally-threaded ends of a pair of collars. Distal to their internally-threaded ends, the collars have filler-material-receiving channels. The channels include plural sloped surfaces for aiding in securing filler material between the collars and the rebar ends. The sloped surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com