Heat exchanger

a heat exchanger and heat exchanger technology, applied in the field of heat exchangers, can solve the problems of unstable available connecting techniques, inability to integrate the heat exchanger into the heat exchanger, and inefficiency of conventional heat exchangers, so as to reduce production costs, improve heat transfer, and increase distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

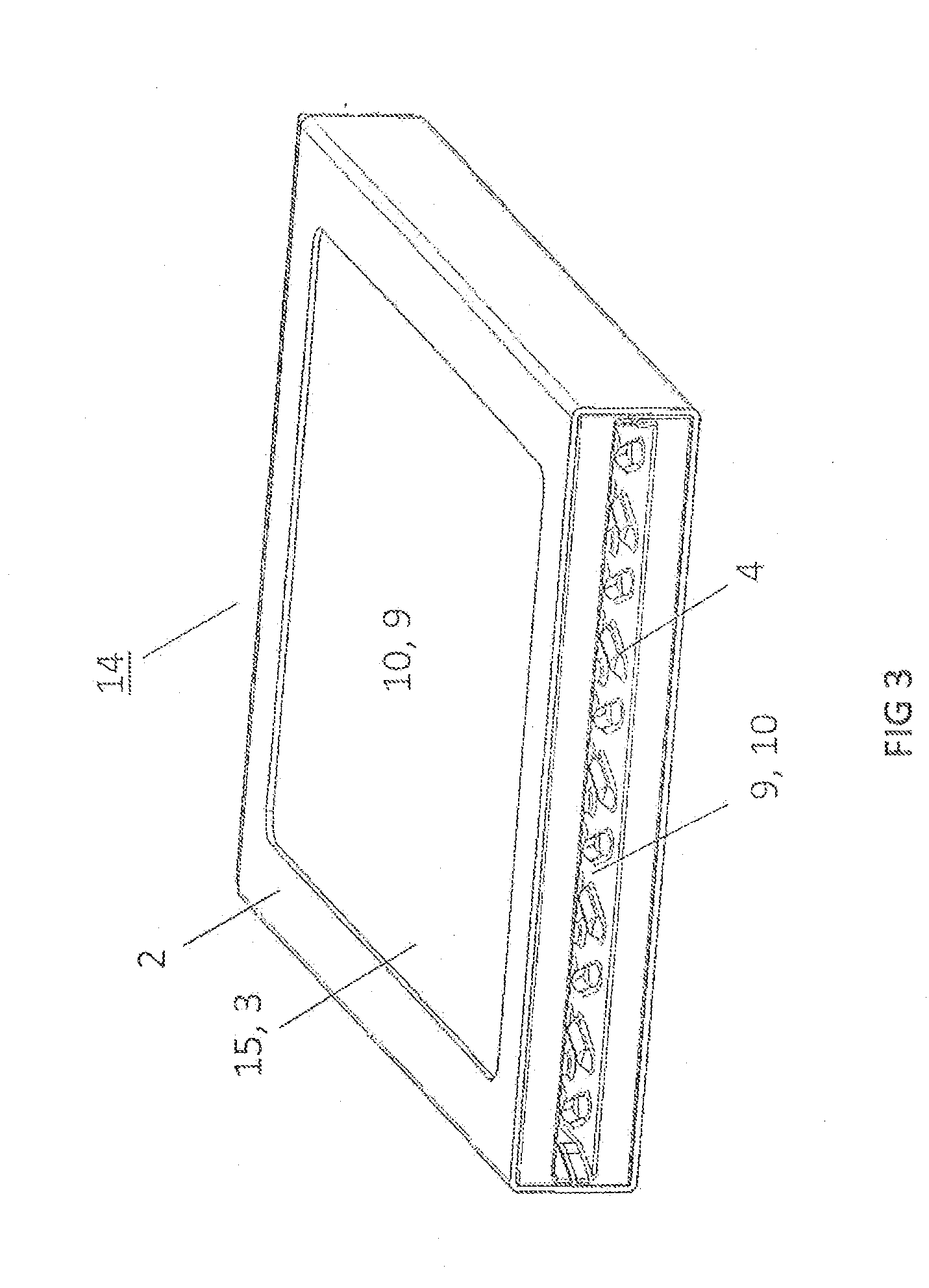

[0050]In the following description of the exemplary embodiments of the present invention, identical or similar reference numerals are used for the elements illustrated in the different drawings and having a similar function, these elements not being described repeatedly.

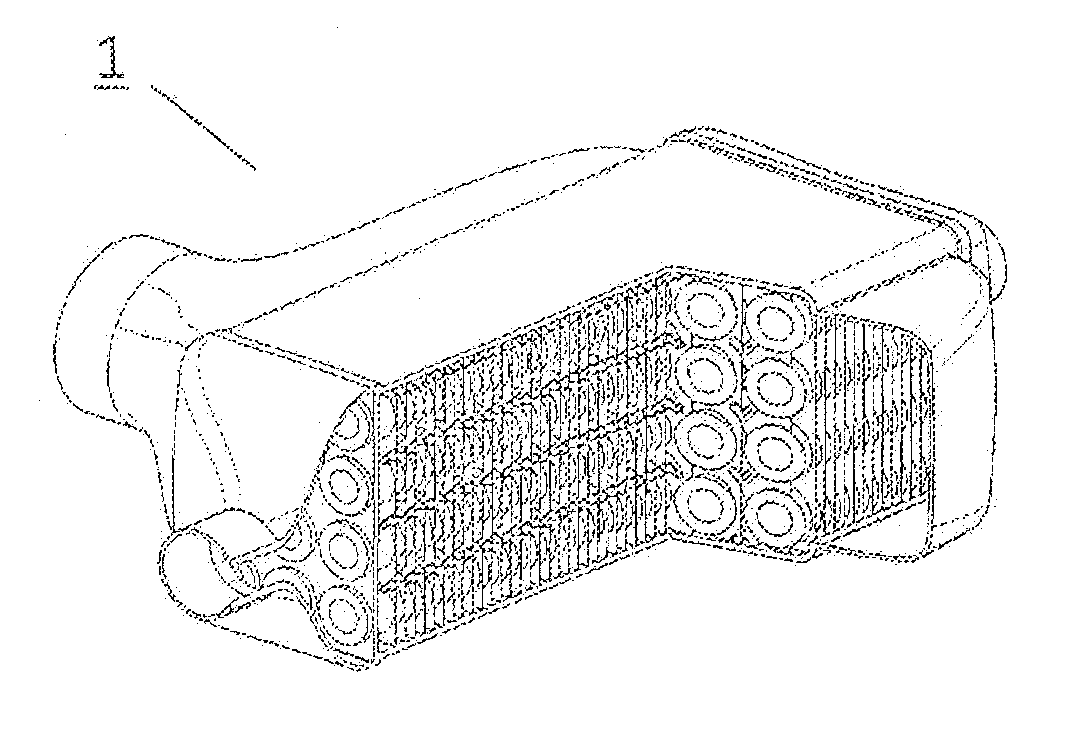

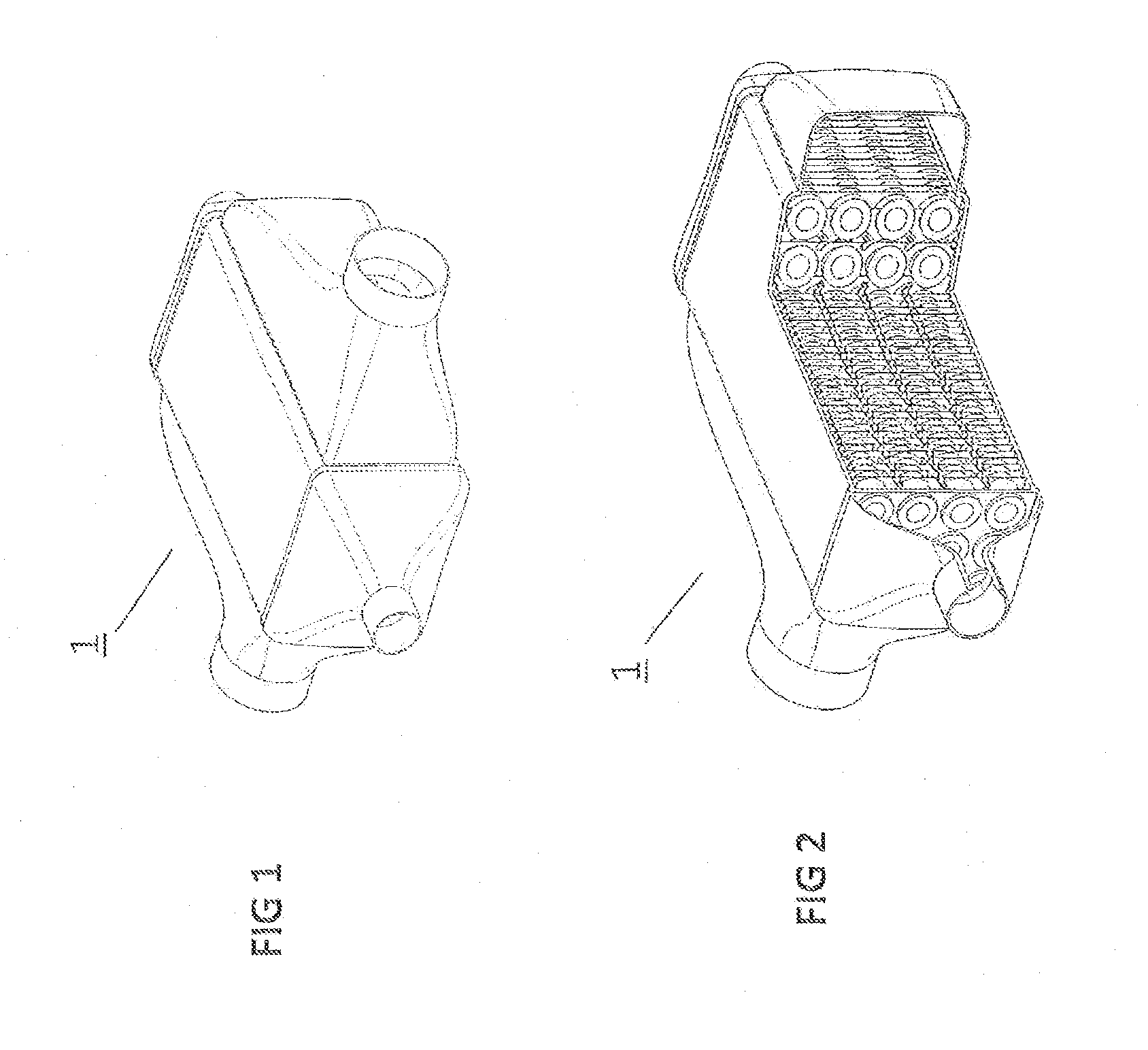

[0051]The heat exchanger according to the invention may be used, for example, as a thermoelectric generator (TEG) for generating electricity in a vehicle.

[0052]In a TEG according to exemplary embodiments of the invention, two media of different temperatures may be conducted past each other in a cross flow along a heat transfer route, so that heat may be transferred from the warm medium to the cold medium. The two media are separated to prevent mixing from occurring. The hot medium is, for example, exhaust gas, and the cold medium is, for example, a water / Glysantin mixture, which may be used as a coolant. The exhaust gas comes from, for example, an internal combustion engine; the water / Glysantin mixture comes from a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com