Heat treatment technology for markedly raising comprehensive performance of aluminium alloy

A comprehensive performance and aluminum alloy technology, which is applied in the heat treatment process of aluminum alloy, and can significantly improve the comprehensive performance of aluminum alloy in the field of heat treatment process. , large damage to production equipment, etc., to achieve the practical application value of large industries, reduce the electrochemical potential difference, and improve the matching effect of strength, plasticity and toughness

Inactive Publication Date: 2011-11-16

CENT SOUTH UNIV

View PDF2 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these methods are limited to the processing of small-sized samples with complex procedures and high equipment requirements, and cannot meet the production requirements of large aluminum alloy components used in large components, or perform extremely dangerous production operations in liquid nitrogen temperature environments. And the damage to the production equipment is relatively large, and the production cost will be further increased at the same time

All in all, these methods have poor operability in actual industrial applications, and their technical routes are far from meeting the requirements of aluminum alloy large structural parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Login to View More

Abstract

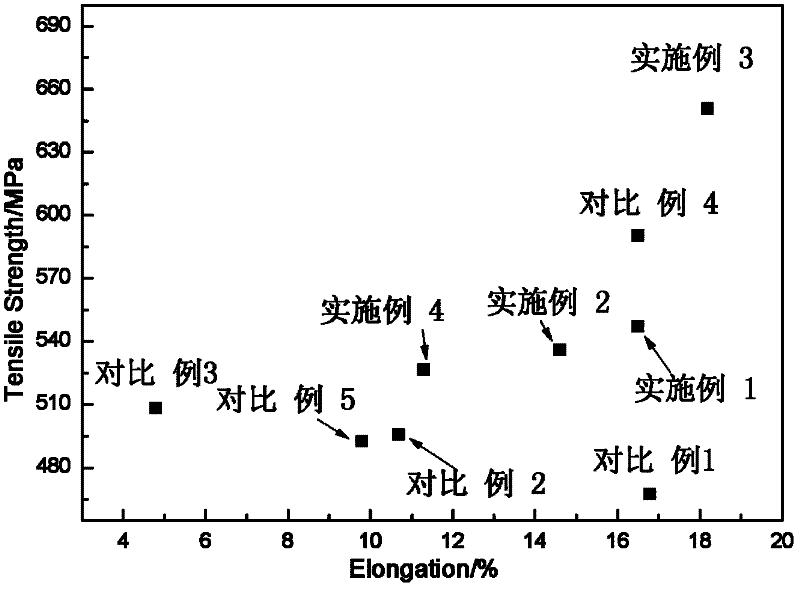

A heat treatment technology for markedly raising comprehensive performance of aluminium alloy is accomplished by the adoption of the following scheme: carrying out a solid solution treatment on the aluminium alloy, taking the aluminium alloy out of a furnace and carrying out water quenching, and carrying out a pre-aging treatment, cold deformation and a secondary aging treatment. Nanometer-level aging precipitation strengthening phase is formed by the pre-aging treatment, and dislocation configuration generated from the subsequent cold deformation can be changed, so as to improve the strength, ductility and toughness of the alloy; during the cold deformation, nanometer-level atomic clusters will precipitate out from solute atoms precipitated during the pre-aging treatment, or ''pinning'' air mass is formed around the dislocation structure, thus further raising the strength of the alloy. The precipitated precipitation strengthening phase is nanometer level, thus raising the ductility and toughness of the alloy and markedly enhancing the strength of the alloy on the basis of guaranteeing good plasticity. The technological process provided by the invention is simple, is convenient to operate, can be adopted to markedly raise comprehensive performance such as the strength and plasticity of the aluminium alloy and improve the corrosion resistant performance and fatigue resistant performance of the aluminium alloy, and is suitable for industrial application.

Description

technical field [0001] The invention relates to a heat treatment process for aluminum alloys, in particular to a heat treatment process for significantly improving the comprehensive performance of aluminum alloys; it belongs to the technical field of nonferrous metal heat treatment processes. technical background [0002] Improving the strength of materials has always been a core issue in materials research. The strengthening of materials is often accompanied by a sharp decrease in plasticity or toughness, while the strength of high plasticity and toughness materials is often very low. For a long time, the "inverted relationship" of strength and toughness of this material has become a bottleneck restricting the development of materials. In order to enable aluminum alloys to further meet the requirements of higher comprehensive performance, the improvement of the comprehensive performance of aluminum alloys has become a hot spot in the aluminum alloy industry in recent years...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22F1/04

Inventor 陈志国黄裕金任杰克

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com