A Thermomechanical Treatment Process for Improving the Comprehensive Properties of Aluminum Alloys

A thermomechanical treatment and comprehensive performance technology, which is applied in the heat treatment process of aluminum alloy and in the field of thermomechanical treatment process to improve the comprehensive performance of aluminum alloy, and can solve the problem that the technical route cannot meet the requirements of aluminum alloy large structural parts and cannot realize aluminum alloy large structural parts. Production demand, large damage to production equipment, etc., to achieve the practical application value of large industries, improve the matching of strength and plasticity, and improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

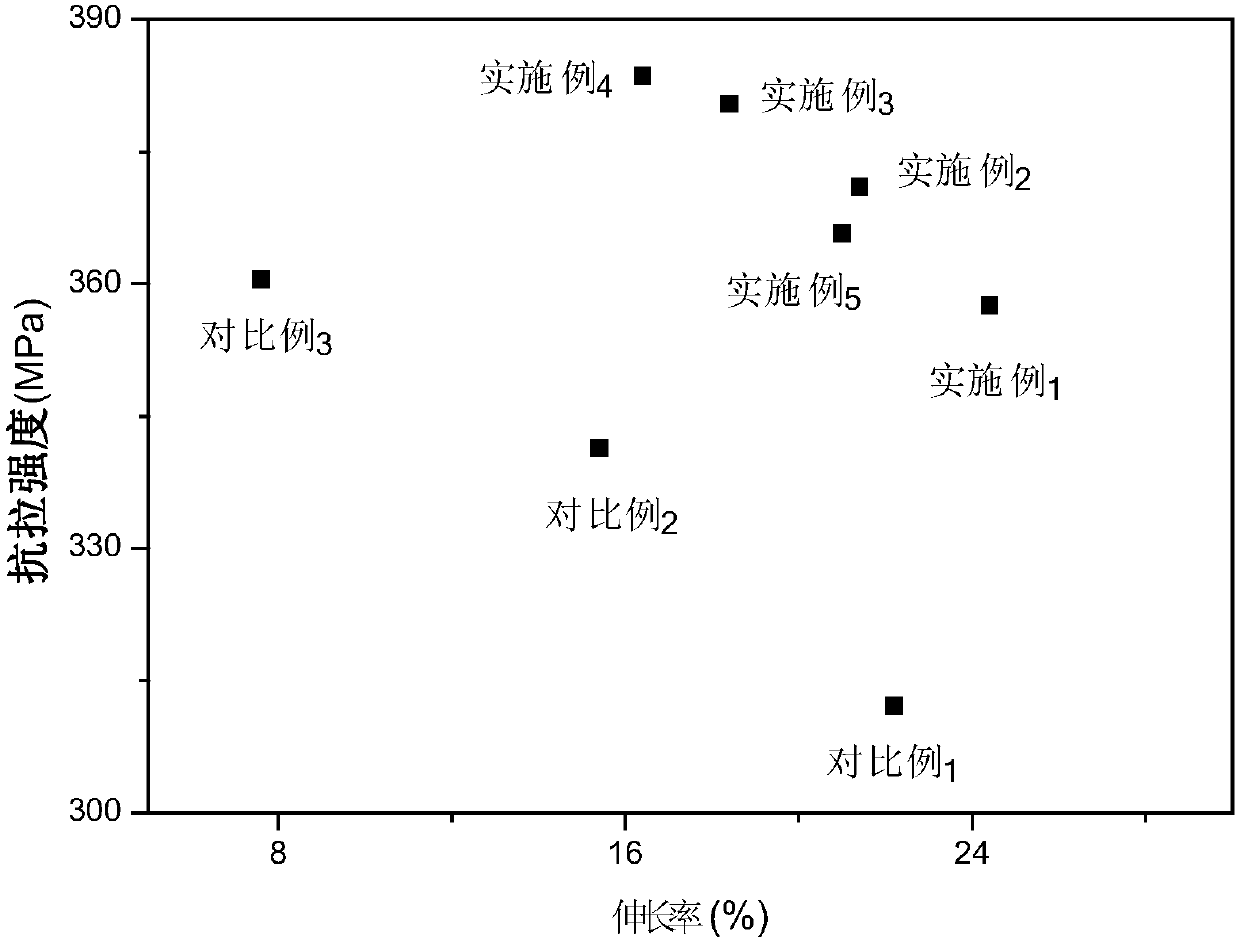

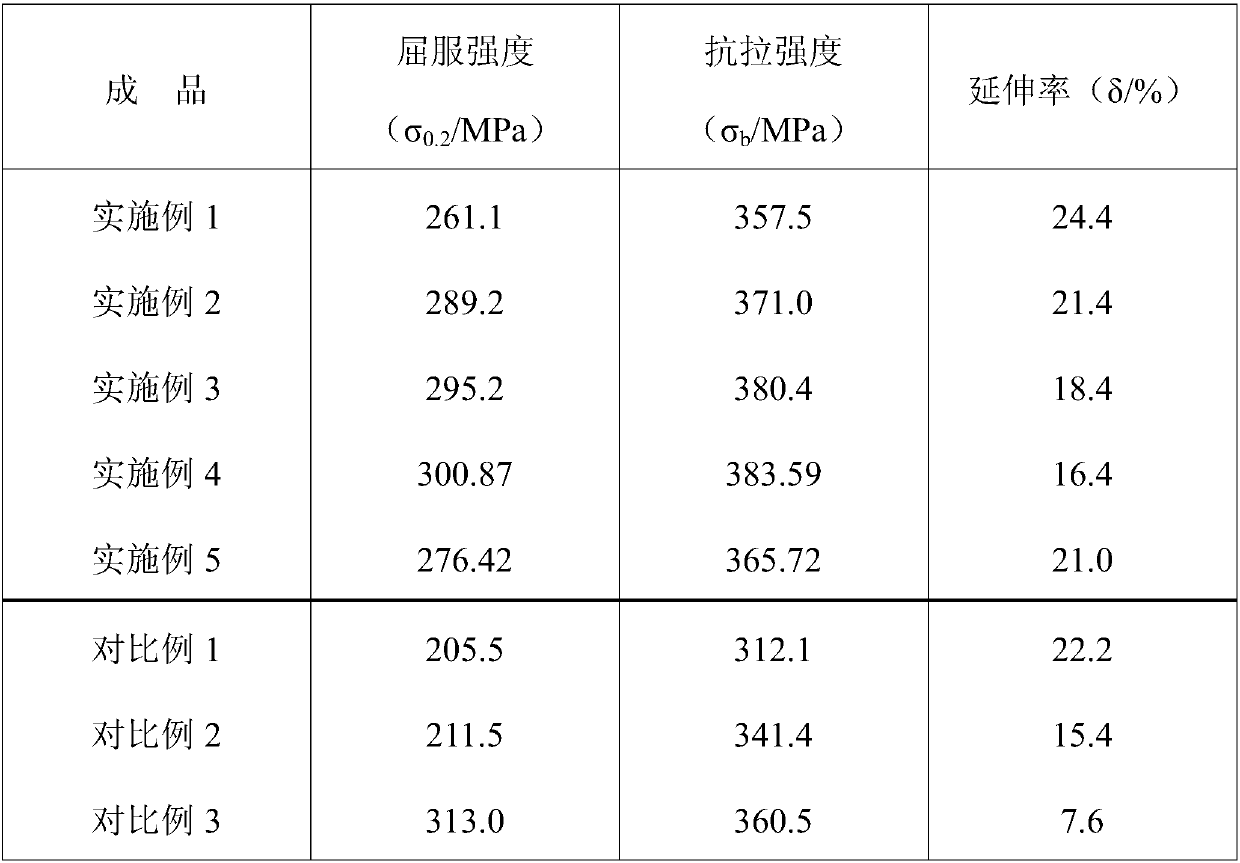

Embodiment 1

[0034] The sample is an Al-1.0Mg-1.0Si-0.9Cu-0.2Zn (mass fraction%) aluminum alloy cold-rolled plate with a thickness of 10.0mm. Put the sample into a salt-bath furnace at 520-530°C for solution treatment, holding time for 1 hour; carry out warm rolling with a deformation of 50% at 300°C, and conduct continuous rolling with a deformation of 60% immediately after warm rolling The thin plate is obtained; the obtained thin plate is subjected to solution water quenching treatment at 520-530°C, and the holding time is 1 hour; then it is put into an aging box for pre-aging treatment, the aging temperature is 100°C, and the aging time is 16h; The conditions of asymmetric rolling are as follows: the speed ratio is 1.1, the deformation is 5%, and the deformation temperature is room temperature; finally, natural aging is carried out for 15 days, and tensile samples are made according to GB228-76. The parameters of yield strength, tensile strength and elongation of the Al-1.0Mg-1.0Si-0.9...

Embodiment 2

[0036] The sample is an Al-1.0Mg-1.0Si-0.9Cu-0.2Zn (mass fraction%) aluminum alloy cold-rolled plate with a thickness of 10.0 mm. Put the sample into a salt-bath furnace at 520-530°C for solution treatment, holding time for 1 hour; carry out warm rolling with a deformation of 50% at 300°C, and conduct continuous rolling with a deformation of 60% immediately after warm rolling The thin plate is obtained; the obtained thin plate is subjected to solid solution water quenching treatment at 520-530°C, and the holding time is 1 hour; then it is put into an aging box for pre-aging treatment, the aging temperature is 60°C, and the aging time is 100h; Rolling, the conditions of asymmetric rolling are: deformation temperature 150°C, different velocity ratio 1.3, deformation amount ~10%; finally carry out artificial aging at 60°C-72h, and make tensile samples according to GB228-76. The parameters of yield strength, tensile strength and elongation of the Al-1.0Mg-1.0Si-0.9Cu-0.2Zn (mass f...

Embodiment 3

[0038] The sample is an Al-1.0Mg-1.0Si-0.9Cu-0.2Zn (mass fraction%) aluminum alloy cold-rolled plate with a thickness of 10.0mm. Put the sample into a salt-bath furnace at 520-530°C for solution treatment, holding time for 1 hour; carry out warm rolling with a deformation of 50% at 300°C, and conduct continuous rolling with a deformation of 60% immediately after warm rolling The thin plate is obtained; the obtained thin plate is subjected to solid solution water quenching treatment at 520-530°C, and the holding time is 1 hour; then it is put into an aging box for pre-aging treatment, the aging temperature is 120°C, and the aging time is 10h; Rolling treatment, the conditions of asymmetric rolling are: deformation temperature 250°C, roll surface speed ratio 1.8, deformation amount ~ 20%; finally carry out artificial aging at 130°C-4h, and make tensile samples according to GB228-76 . The parameters of yield strength, tensile strength and elongation of the Al-1.0Mg-1.0Si-0.9Cu-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com