A heat treatment process that significantly improves the comprehensive performance of aluminum alloys

A comprehensive performance and alloy technology, which is applied in the field of heat treatment of non-ferrous metals, can solve problems such as poor operability, increased production costs, and large damage to production equipment, so as to improve the strength-plastic fit, improve alloy toughness, and avoid growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

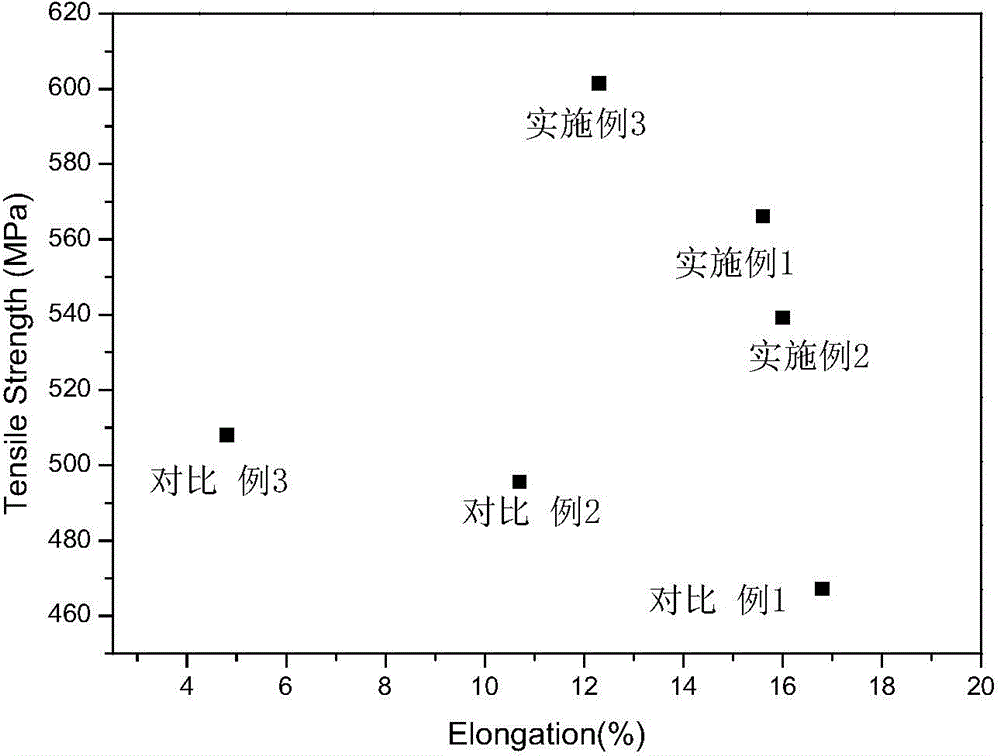

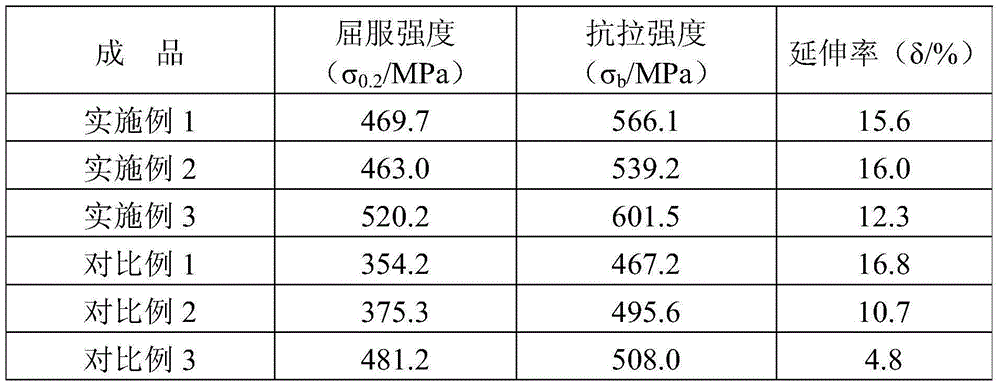

Embodiment 1

[0021] The sample adopts Al-4.45Cu-1.5Mg-0.54Mn aluminum alloy cold-rolled sheet with a thickness of 2.0mm. According to GB228-76 to make tensile samples. Put the sample into a salt bath furnace at 495-505°C for solid solution treatment, take it out and quench it immediately; then put it into an aging box for pre-aging treatment, the aging temperature is 100°C, and the aging time is 12h; then asymmetric rolling The surface speed ratio of the roll is 1.3, the deformation is ~9%, and the deformation temperature is room temperature; finally, it is artificially aged at 100°C for 48 hours. The yield strength, tensile strength and elongation parameters of the Al-4.45Cu-1.5Mg-0.54Mn aluminum alloy treated in this example are shown in Table 1.

Embodiment 2

[0023] The sample adopts Al-4.45Cu-1.5Mg-0.54Mn aluminum alloy cold-rolled sheet with a thickness of 2.0mm. According to GB228-76 to make tensile samples. Put the sample into a salt bath furnace at 495-505°C for solid solution treatment, take it out and quench it immediately; then put it into an aging box for pre-aging treatment, the aging temperature is 100°C, and the aging time is 6h; Rolling, the deformation temperature is 250°C, the surface speed ratio of the roll is 1.1, and the deformation is ~10%; finally, natural aging is carried out for 12 days. The yield strength, tensile strength and elongation parameters of the Al-4.45Cu-1.5Mg-0.54Mn aluminum alloy treated in this example are shown in Table 1.

Embodiment 3

[0025] The sample adopts Al-4.45Cu-1.5Mg-0.54Mn aluminum alloy cold-rolled sheet with a thickness of 2.0 mm. According to GB228-76 to make tensile samples. Put the sample into a salt bath furnace at 495-505°C for solid solution treatment, take it out and quench it immediately; then put it into an aging box for pre-aging treatment, the aging temperature is 60°C, and the aging time is 60h; Rolling treatment, the deformation temperature is 150°C, the surface speed ratio of the roll is 1.5, and the deformation is ~40%; finally, the final aging is carried out at 150°C-8h. The yield strength, tensile strength and elongation parameters of the Al-4.45Cu-1.5Mg-0.54Mn aluminum alloy treated in this example are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com