Titanium alloy welding method based on arc ultrasonic process

A welding method, titanium alloy technology, applied in arc welding equipment, welding equipment, non-electric welding equipment and other directions, can solve the problems that have not been discussed in depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

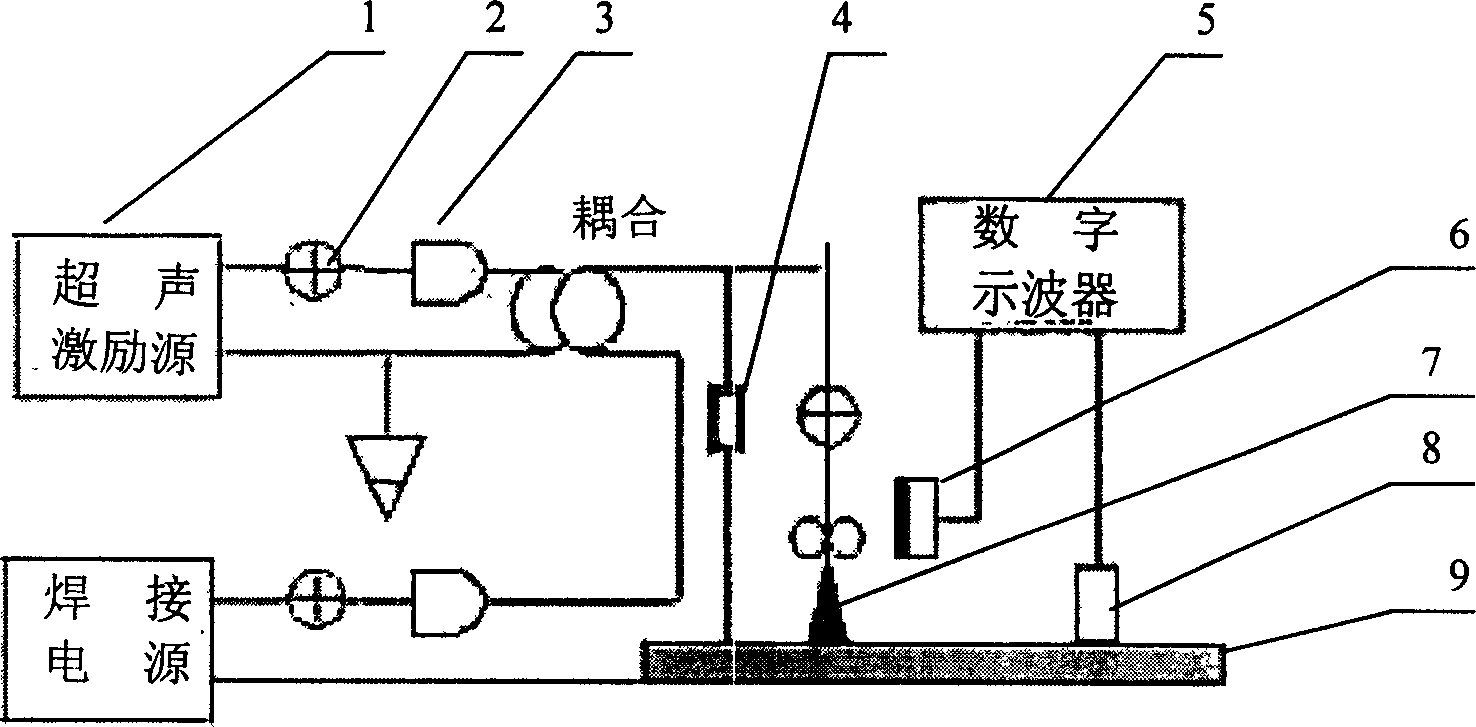

[0017] figure 1 It is a schematic diagram of the test device of the method of the present invention. Arc ultrasonic titanium alloy welding uses the welding arc not only as a heat generating mechanism, but also as an ultrasonic emission mechanism, which in turn affects the welding metallurgical process of titanium alloys. The arc ultrasonic excitation source 1 can generate an ultrasonic frequency alternating electric signal whose frequency is continuously adjustable from 20 kHz to 500 kHz, and the waveform and power of the signal are both adjustable. After coupling with the welding power source, the welding is carried out according to the conventional titanium alloy arc welding method. The arc plasma is excited by the ultrasonic frequency electric signal to emit ultrasonic waves, which act on the molten pool of the titanium alloy weld to improve the structure and properties of the weld.

[0018] The specific steps of the arc ultrasonic welding method provided by the invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com