Added material manufacturing method under vibration condition

An additive manufacturing and condition technology, applied in the field of arc wire feeding additive manufacturing and laser powder feeding melting additive manufacturing, can solve the problems affecting the machining accuracy of parts, parts cracking, inclusions, etc., to improve the quality and yield, eliminate the Porosity and inclusions, residual stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

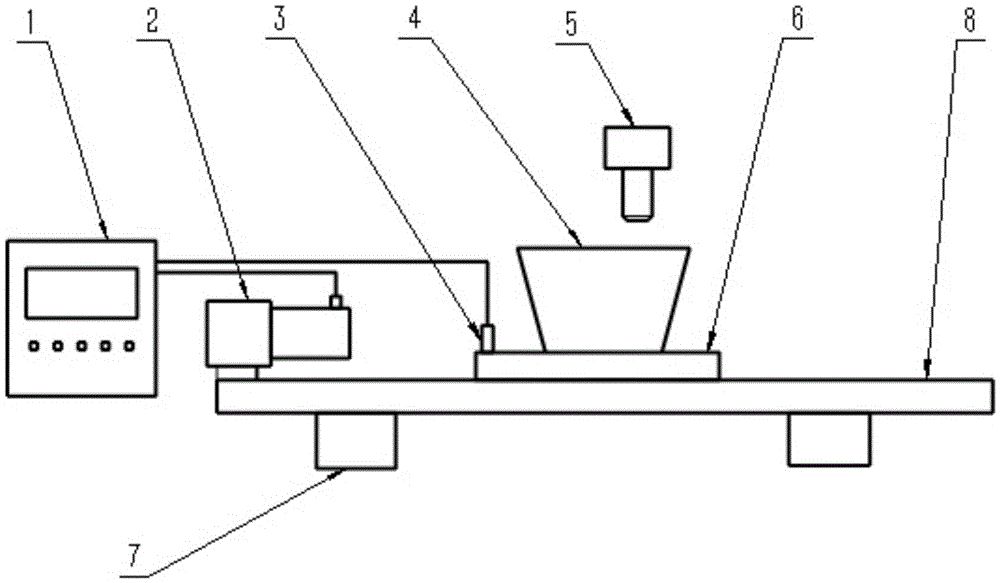

[0035] As mentioned above, the selected additive manufacturing method for additive manufacturing under vibration conditions is arc wire feeding additive manufacturing. The exciter is an eccentric motor, and its working time and vibration acceleration are set through the vibration control cabinet; the selected filler material is 1.0 mm in diameter. mm ER85-G high-strength steel welding wire, the corresponding best vibration acceleration is 17m / s 2 , the vibrating platform is made of rigid material, the material is Q235 rolled steel plate, the wire feeding speed is 4m / min, the welding speed is 3mm / s, the eccentric angle of the eccentric motor is 20°, and the corresponding motor speed is 2268r / min, The size of the vibration platform is 2700mm×800mm×50mm,

[0036] (1) Preparatory work, fixing the eccentric motor and the additive manufacturing substrate on the vibration platform, the vibration platform is made of rigid materials; where four rubber pads are placed under the vibratio...

Embodiment 2

[0041] As mentioned above, the selected additive manufacturing method for additive manufacturing under vibration conditions is arc wire feeding additive manufacturing. The exciter is an eccentric motor, and its working time and vibration acceleration are set through the vibration control cabinet; the selected filler material is 1.2 in diameter. mm aluminum-magnesium alloy welding wire, the vibrating platform is made of rigid material Q235 rolled steel plate, the wire feeding speed is 9.4m / min, the welding speed is 6mm / s, the eccentric angle of the eccentric motor is 20°, the rotational speed of the motor 2300r / min, the vibration acceleration of the substrate placement position is 20m / s 2 , the size of the vibration platform is 2700mm×800mm×50mm,

[0042] (1) Preparatory work, fix the exciter and the additive manufacturing substrate on the vibration platform, the vibration platform is made of rigid materials; where four rubber pads are placed under the vibration platform, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com