High-performance natural rubber vulcanized rubber of carbon-containing nano-tube, and preparation method thereof

A technology of natural rubber and carbon nanotubes, applied in the direction of dyeing organosilicon compound treatment, fibrous fillers, etc., can solve the problems of low strength, uneven dispersion and low elongation of composite materials, and improve the wear resistance performance. and tear strength, avoid local high temperature, and improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

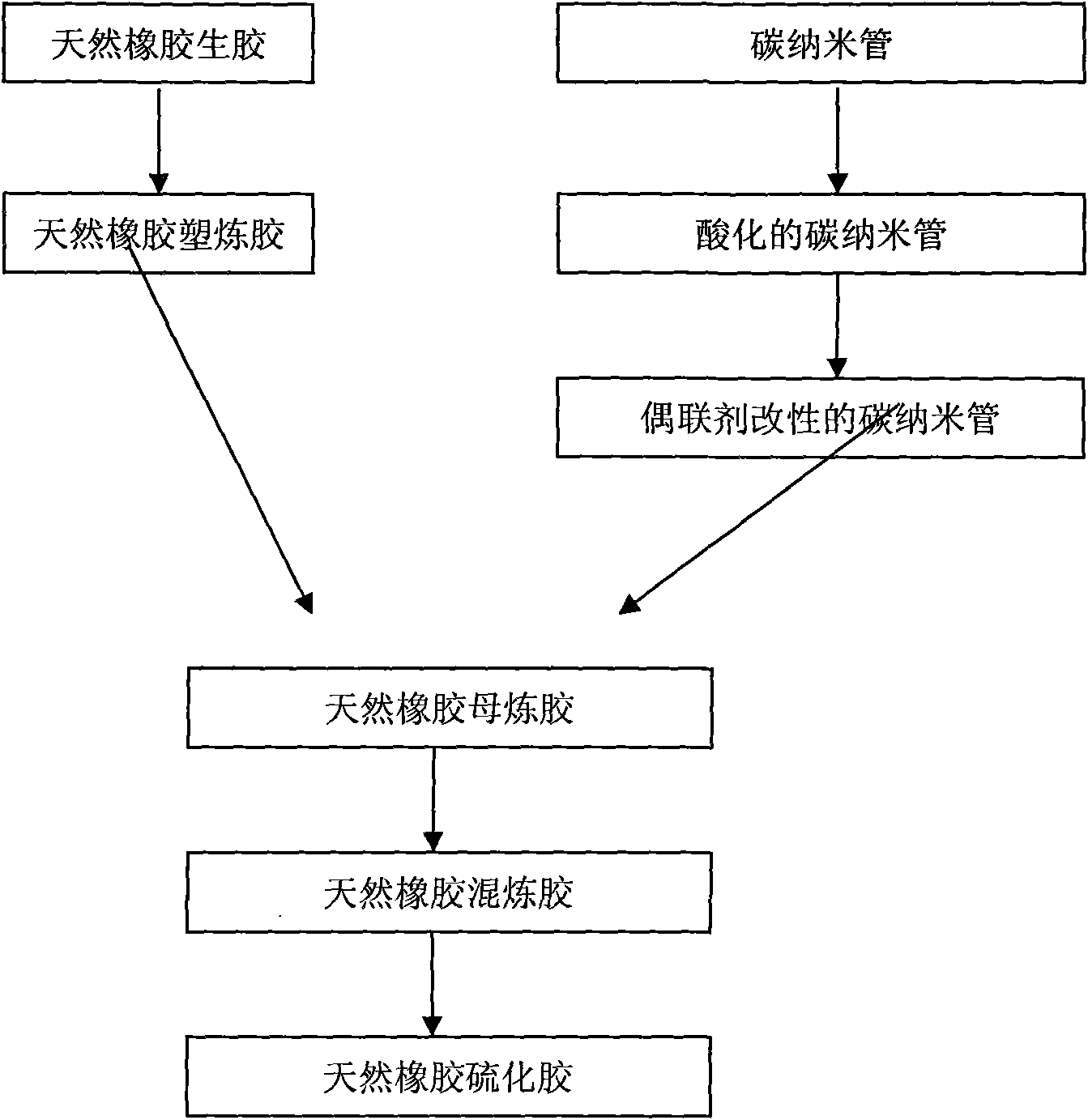

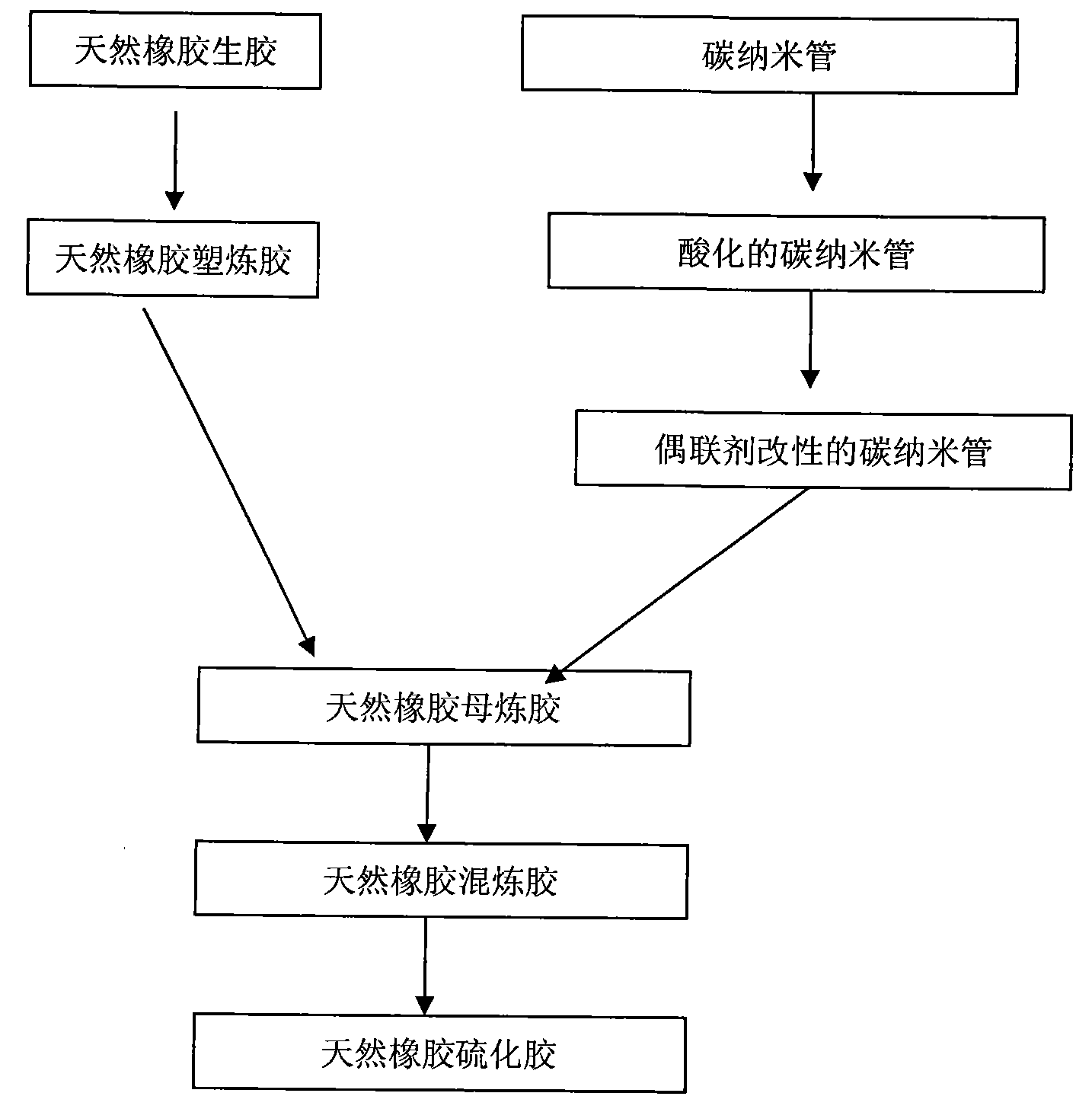

[0022] The preparation method of the high-performance natural rubber vulcanizate containing carbon nanotubes of the present invention comprises the following steps:

[0023] Step 1: Surface treatment of carbon nanotubes: Weigh multi-walled carbon nanotubes MWNTs raw materials, add nitric acid solution, the concentration of nitric acid solution is 2-3mol / L, transfer to the reaction container after ultrasonic dispersion, the ultrasonic dispersion time is 20-60min, heat in an oil bath, transfer to another container after reflux reaction, reflux time is 10-24h, stand still, remove the supernatant, add deionized water to wash, repeat the above cleaning process until the solution is neutral, Then use a microporous membrane for suction filtration, and a 0.22um microporous membrane can be used for suction filtration, and dry it in an oven for standby use at a temperature of 80-100°C.

[0024] Step 2: Surface modification of carbon nanotubes: Weigh the MWNTs treated in step 1 and place...

Embodiment 1

[0031]Preparation of modified carbon nanotube reinforced natural rubber compound. Select carbon nanotubes with a diameter of 20-40nm, acidify with dilute nitric acid, filter, dry at 100°C, and modify with bistriethoxytrisilane tetrasulfide (Si69) to obtain a master rubber. Thailand No. 3 smoke sheet rubber was mixed evenly on the open mill according to the ratio of modified MWNTs and natural rubber at 1:100, and 4 parts of anti-aging agent RD, 1 part of anti-aging agent 4010NA, 5 parts of ZnO, 3 parts of stearic acid, 0.3 1 part of accelerator CZ, 0.3 part of accelerator NOBS, 2 parts of coumarone resin, 3 parts of sulfur, 0.5 part of anti-scorch agent CTP, 43 parts of carbon black, and knead evenly on the open mill. After the refined mixed rubber is parked for 24 hours, the corresponding normal vulcanization time is measured. The compound was vulcanized on a flat vulcanizing machine at 143°C. The tensile strength of the compound is 22.9MPa, the elongation at break is 508%, ...

Embodiment 2

[0033] Repeat the method of Example 1 according to the specified content of each component, but adopt 40 parts of carbon black, 4 parts of modified MWNTs in the formula, the tensile strength of the vulcanizate obtained is 24.7MPa, the elongation at break is 545%, Acron Abrasion value 0.03cm3 / 1.61km, tear strength 98KN.m -1 , the thermal oxygen aging coefficient is 95%, the number of tensile fatigue fractures is 975,000 times, and the thermal conductivity is 0.415.w / m.k

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com