Composition for water-based electric heating nano paint, water-based electric heating nano paint as well as preparation method and application of water-based electric heating nano paint

A nano-coating and composition technology, applied in the direction of conductive coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor adhesion, high cost, easy to fall off, etc., to increase compatibility, develop Stable heat and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

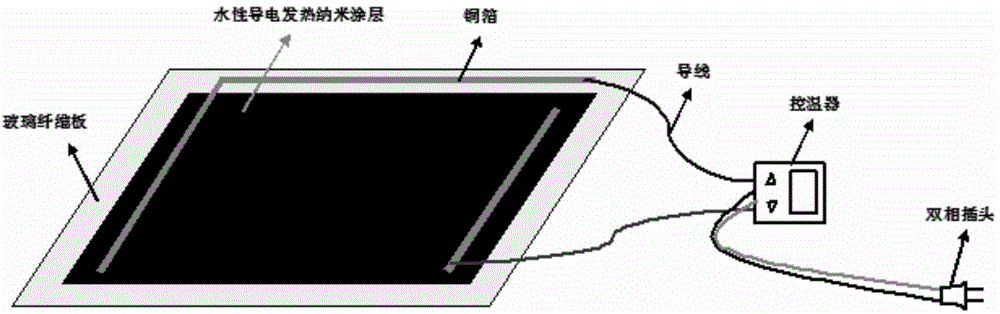

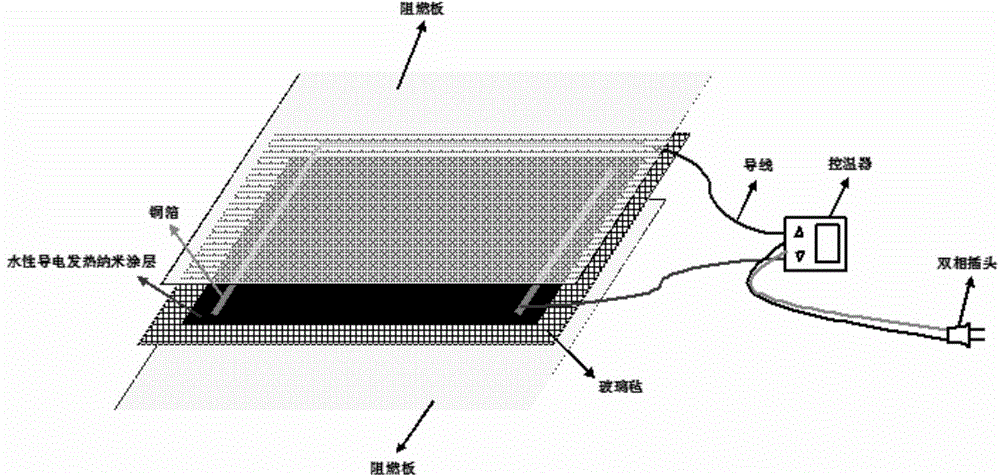

Image

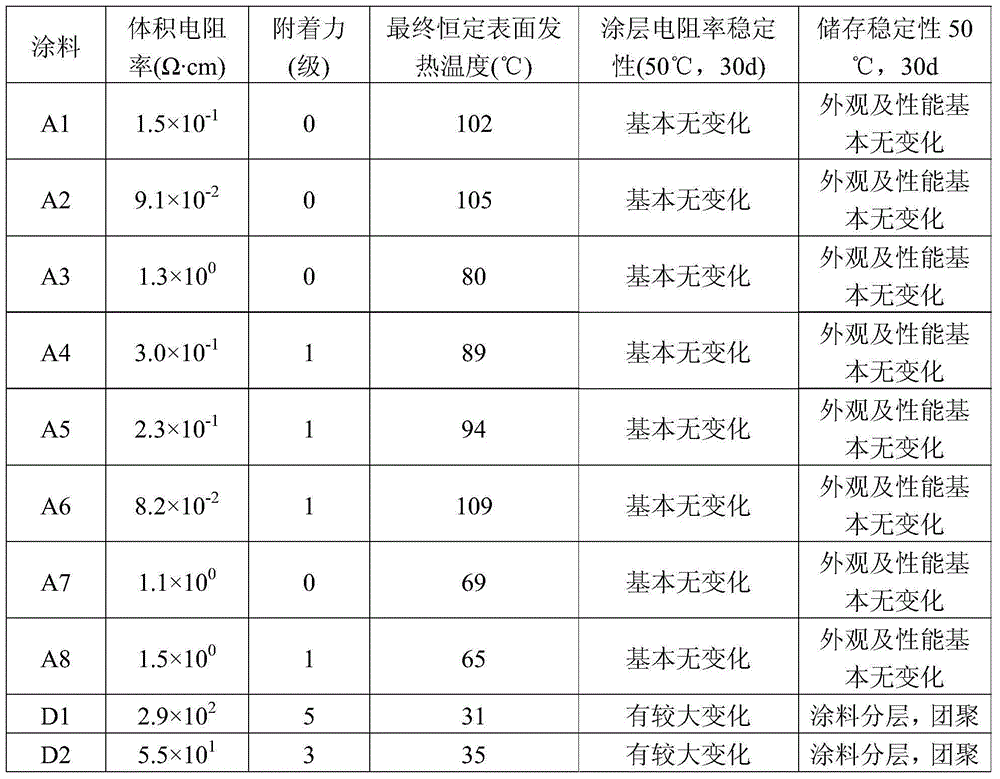

Examples

Embodiment approach

[0025] The inventors of the present invention found in the process of research that by using the aqueous dispersion containing carboxylated modified carbon nanotubes and the aqueous dispersion containing graphene in combination, the dispersibility and electrical conductivity of the coating obtained can be improved. , stability, adhesion, etc. can be significantly improved. Therefore, according to a preferred embodiment of the present invention, the aqueous dispersion containing conductive nanoparticles includes an aqueous dispersion containing carboxylated carbon nanotubes and an aqueous dispersion containing graphene. Wherein, in the coating composition, the aqueous dispersion containing carboxylated carbon nanotubes and the aqueous dispersion containing graphene also exist separately. Preferably, in order to facilitate the proportioning and use, each component in the coating composition is stored according to a certain ratio, for example, in terms of the conductive nanoparti...

preparation example

[0066]Aqueous dispersion containing carbon nanotubes 1: 10 g of multi-walled carbon nanotubes were subjected to ultrasonic treatment, the temperature of the ultrasonic treatment was 25° C., the frequency was 53 KHz, and the time of ultrasonic treatment was 15 minutes. Then disperse the treated multi-walled carbon nanotubes in 400ml mixed acid solution (concentrated sulfuric acid:concentrated nitric acid=3:1)), heat in a water bath for 6h, carry out carboxylation modification, graft hydrophilic soluble groups, and then ultrasonically disperse , the temperature of ultrasonic treatment is 25°C, the frequency is 53KHz, and the time is 30min. The modified carbon nanotube powder is obtained after centrifugal sedimentation, separation and drying. Take 10g of the modified carbon nanotube powder and add 0.95g of hexadecyltri Methyl ammonium bromide and 189.05 g of water were used to prepare a 5% carbon nanotube dispersion. Then, the dispersion liquid was ultrasonicated for 30 min under...

Embodiment 1

[0071] This embodiment is used to illustrate the water-based electrothermal nano coating of the present invention.

[0072] Add 30g of water, 1.2g of dispersant SN5027, 1.2g of wetting agent BYK180, 0.8g of defoamer BYK1610 into the stirring tank, and use the amine neutralizer DMAE to adjust the pH value of the resulting mixture to 8 at a speed of 300rpm After stirring for 10 minutes, add 10 g of conductive carbon black and 10 g of non-conductive titanium dioxide, and stir for 2 hours at a speed of 2000 rpm, then put the material into a conical mill for grinding, and adjust the fineness to less than 50 μm. After grinding, add 60g water-based polyurethane resin (), 1.0g dispersant SN5027, 0.6g defoamer BYK024, 4.4g film-forming aid Texanol, 0.6g rheological additive RM8W, 30g aqueous dispersion containing graphene 1, 50g The aqueous dispersion 1 containing carbon nanotubes was stirred at a speed of 1200 rpm for 30 minutes and then discharged to obtain the electrothermal nano-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com