Carbon nano tube surface functionalization method

A technology of surface functionalization and carbon nanotubes, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as carbon nanotube structure damage, improve interface stability, simple steps, and improve adhesion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

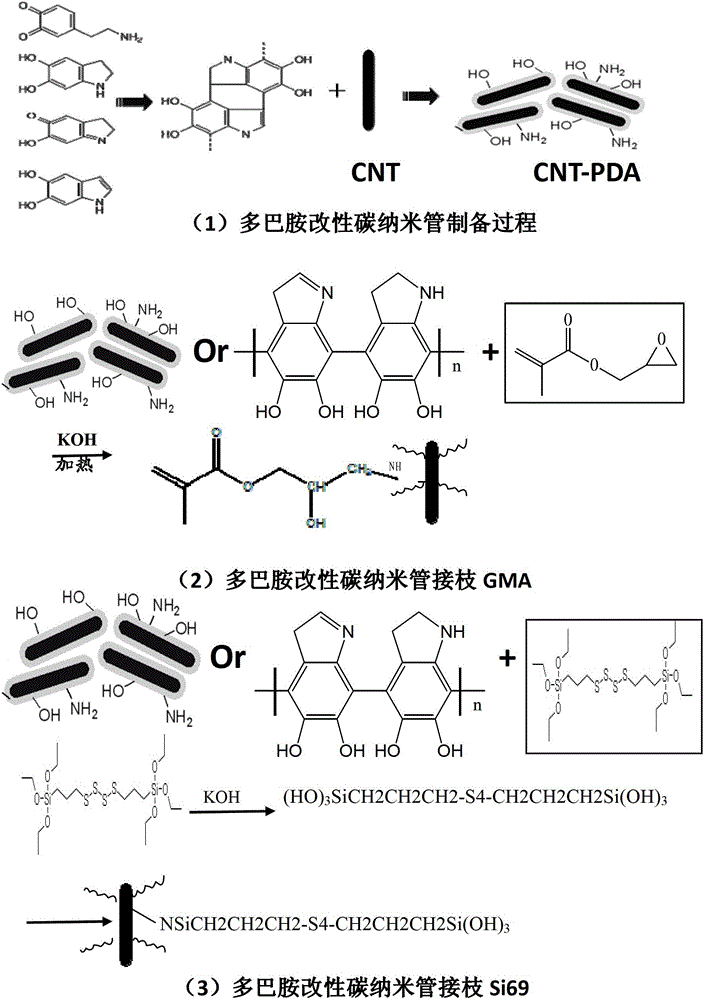

[0031] Such as figure 1Shown in (1), a preparation method of dopamine-coated carbon nanotubes, the method comprises the following steps:

[0032] Prepare a dopamine hydrochloride solution with a concentration of 2.0g / L, add tris (trishydroxymethylaminomethane) buffer substance, adjust the pH of the solution to about 8.5, wash a certain amount (0.2g / 100mL) and dry it Place the carbon nanotubes in the prepared solution, stir and ultrasonically disperse for 20mins, then stir for 24 hours to prepare dopamine-coated carbon nanotubes (CNTs-PDA), and the obtained CNTs-PDA is washed 4 times with deionized water Then dry for future use.

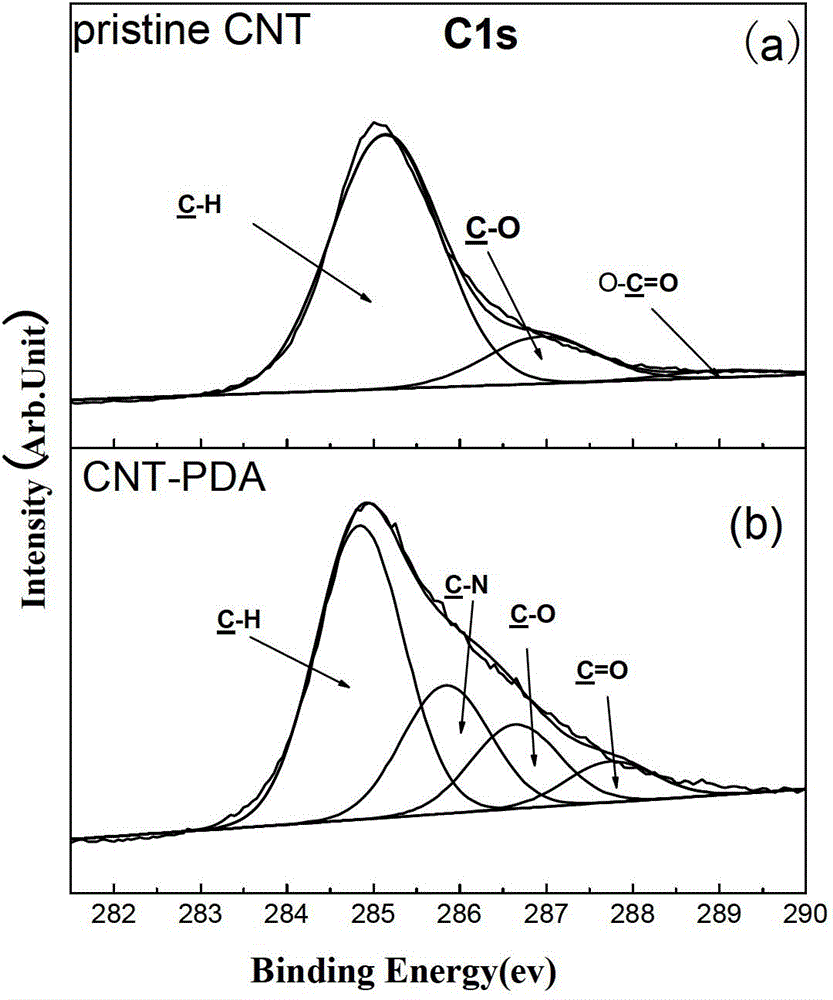

[0033] From figure 2 The analysis of the sample C1s before and after dopamine deposition shows that before and after the deposition of dopamine, the carbon nanotube surface C element binding state has a unique C-N structure of dopamine, and the disappearance of carboxyl bound carbon and the appearance of carbonyl carbon all indicate that dopamine h...

Embodiment 2

[0035] After the carbon nanotubes are coated with dopamine, the preparation method of the functionalized carbon nanotubes CNTs-PDA-GMA which is further functionalized by GMA:

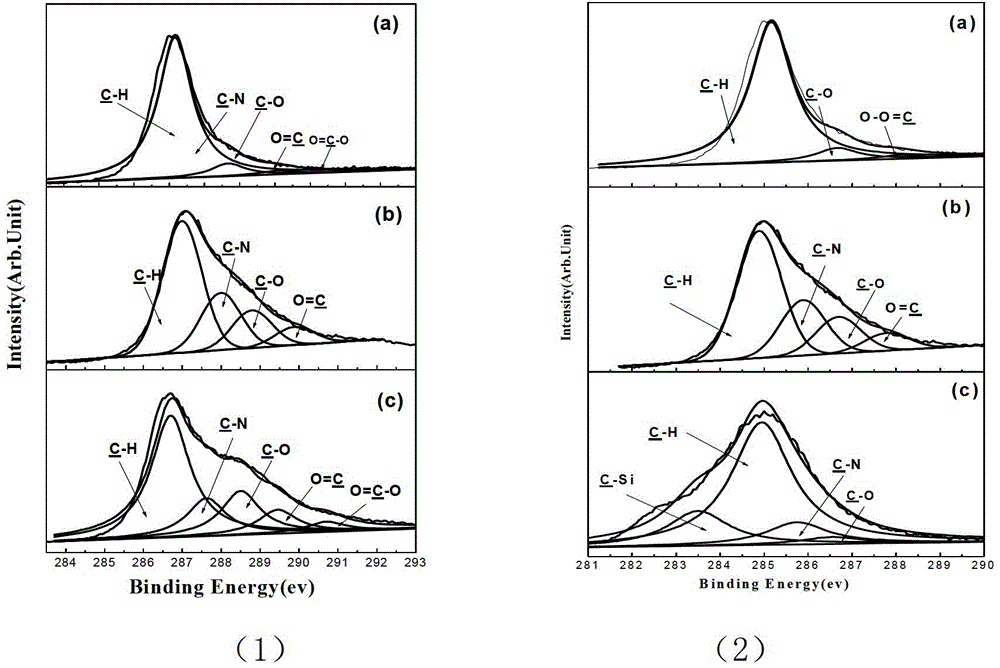

[0036] Such as figure 1 As shown in (2), prepare a reaction solution with a volume ratio of water and N-N dimethylformamide (DMF) of 2:1, and add the dry dopamine-coated carbon nanotubes obtained in Example 1 at a rate of 0.1 g / 100 mL, After ultrasonic dispersion for 10 minutes, add the secondary functionalized monomer GMA, the monomer addition amount is 5 g / L, adjust the pH value of the reaction solution to 8.5, and react at the temperature of 60, 80, 100, and 120 degrees Celsius respectively After 4 hours, the obtained secondary functionalized carbon nanotubes were washed three times with ethanol and three times with deionized water, and then dried to obtain the final product.

[0037] Such as figure 1 As shown in (2), prepare a reaction solution with a volume ratio of water and N-N dimethylformamid...

Embodiment 3

[0043] Such as figure 1 As shown in (3), prepare a reaction solution with a volume ratio of water and ethanol of 2:1, add the dry dopamine-coated carbon nanotubes obtained in Example 1 at a rate of 0.1 g / 100 mL, and ultrasonically disperse for 10 minutes. Secondary functionalized monomeric silane coupling agent, the amount of monomer added is 1, 2.5, 5 g / L respectively, adjust the pH value of the reaction solution to 8, react for 5 hours, and the obtained secondary functionalized carbon nanotubes are washed with ethanol in turn 3 times, washed with deionized water for 3 times and then dried to obtain the final product.

[0044] Such as figure 1 As shown in (3), prepare a reaction solution with a volume ratio of water and ethanol of 2:1, add the dry dopamine-coated carbon nanotubes obtained in Example 1 at a rate of 0.1 g / 100 mL, and ultrasonically disperse for 10 minutes. Secondary functionalized monomeric silane coupling agent, the amount of monomer added is 2.5g / L, the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com