Modified carbon products, their use in bipolar plates and similar devices and methods relating to same

a technology of bipolar plates and carbon products, which is applied in the field of bipolar plates, can solve the problems of increasing the brittleness of bipolar plates and the performance of fuel cells, and achieve the effect of increasing the hydrophobicity of the first carbonaceous surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

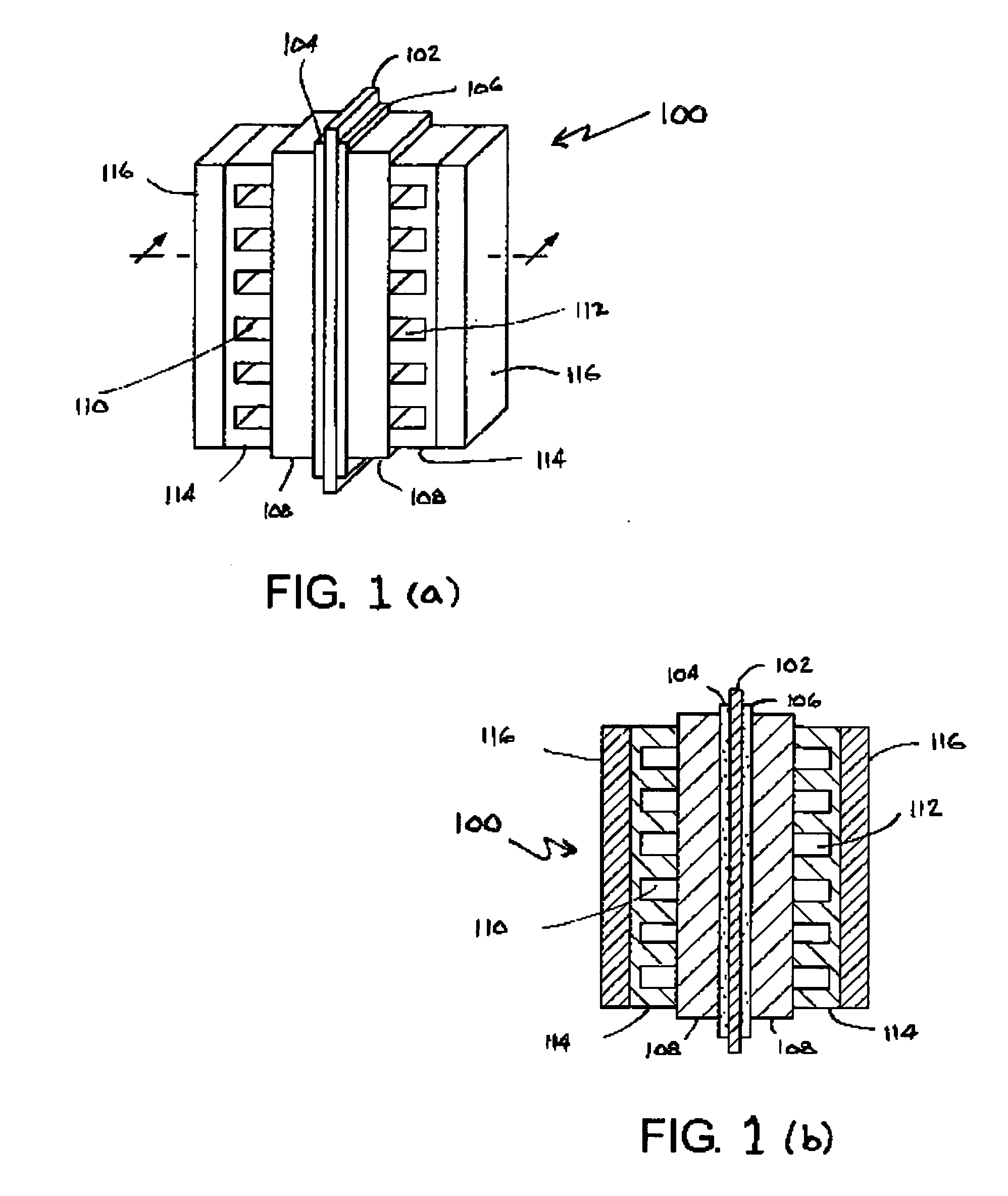

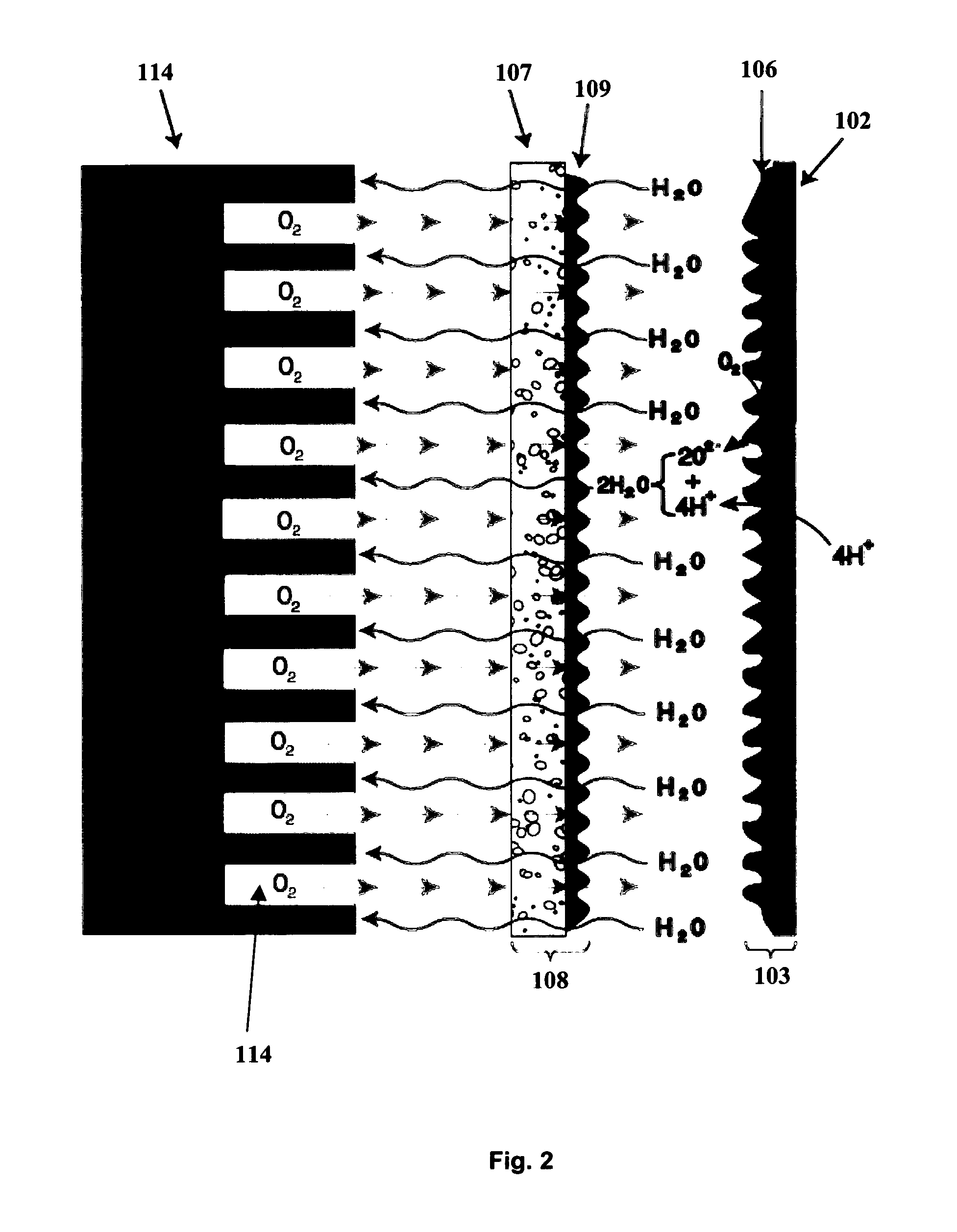

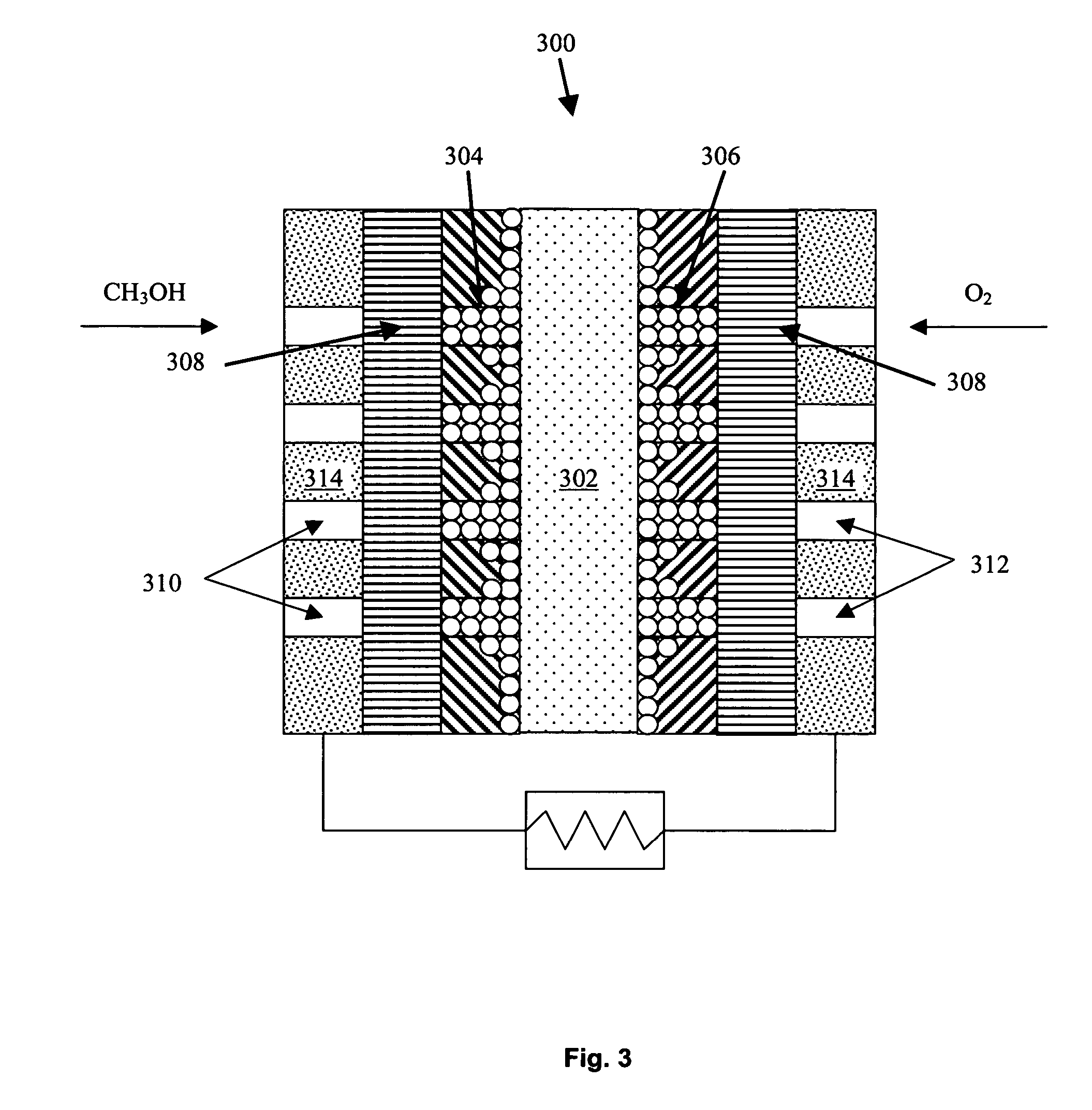

Image

Examples

examples

1. Surface Modification of a Machined Graphite Bipolar Plate with a Hydrophilic Modifying Group

[0177] 270 ml of deionized water, 6.48 g of a functionalizing (treating) agent (H2NC6H4SO3H) and 6.75 g of a 70% aqueous solution of nitric acid are added to a beaker and slowly mixed. The temperature is slowly raised to 40° C. using a hot plate. When the temperature reaches 40° C., a machined graphite bipolar plate is immersed into the solution and the solution is continually stirred and heated to 50° C. When the temperature reaches 50° C., 12.9 g of a 20 wt. % aqueous sodium nitrite solution is added slowly dropwise. The mixture is then allowed to react at 50° C. for 24 hours. The graphite plate is removed and washed with deionized water three times and dried at 50° C. overnight.

2. A Polymer / Resin Type Bipolar Plate Incorporating a Peg Modified Carbon

[0178] 90 ml of deionized water, 26.5 g treating agent (aminophenylated polyethylene glycol ether (MW 2119) (H2N—C6H4—CO—[O—(C2H4O)n—C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| volume average particle size | aaaaa | aaaaa |

| volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com