Processing method of sewage in oil fields by using film evaporator

A technology of oilfield sewage and membrane evaporator, which is applied in the direction of chemical instruments and methods, mining wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of unsatisfactory oilfield sewage effect, complicated process, waste of resources, etc., and achieve the reduction of wastewater Effects of treatment cost, large evaporation area, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

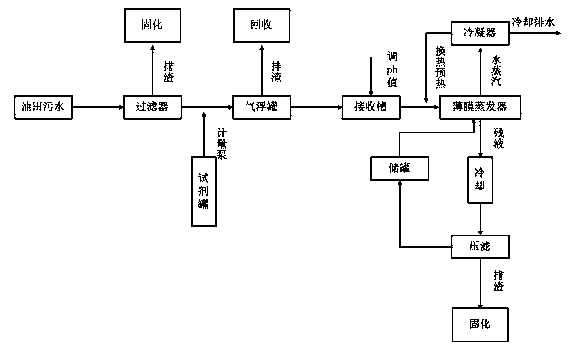

[0016] Example 1, such as figure 1 As shown, taking the oilfield sewage treatment as an example, the large-particle solid matter is removed through a vacuum ceramic filter. The pore size is selected according to the particle size distribution of the solid particles in the water, and the solid matter is solidified; Add medicaments, PAC100-500ppm or PAM5-50ppm alone, or mix and add, through the air flotation device, carry out air flotation treatment on waste oil, so that the oil in the waste water can be recovered and reused as refining raw materials; air flotation The final sewage is driven into the receiving tank through the water pump, and the pH value is adjusted in the tank. The pH value is 4-10. After preheating, it enters the thin film evaporator. The vapor pressure is higher than that of other electrolytes, so in the thin film evaporator, water will be vaporized first; due to the evaporation of water, the salts in the wastewater are concentrated, and after concentration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com