Oily sewage processing method

A treatment method and technology of sewage treatment plant, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Achieve the effect of low cost, low renovation cost, and improved electrical desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

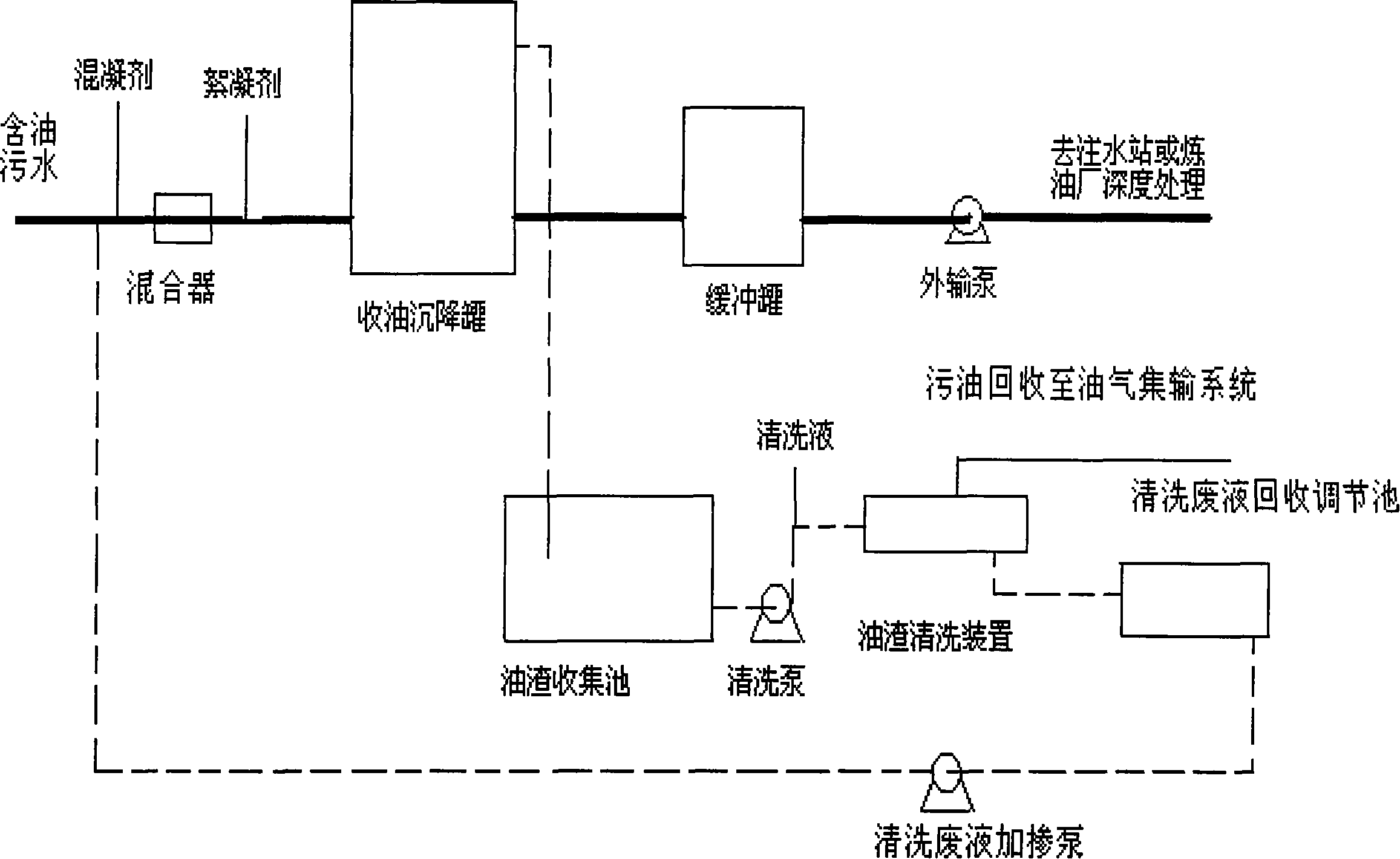

[0017] The method of the present invention effectively solves the problems of secondary pollution caused by discharge, high treatment cost and low recovery rate of waste oil in the existing oily sewage treatment technology. The specific operation steps and procedures are as follows:

[0018] (1) Add coagulant directly to the oily sewage pipeline after being transported to the sewage treatment plant, and transport the oily sewage mixed with coagulant into the mixer, and fully mix the coagulant and oily sewage in the mixer and The reaction occurs to break the gel and demulsify the sewage and form tiny oily alum flowers;

[0019] (2) After the oily sewage that has completed gel breaking and demulsification flows out of the mixer, polymer organic flocculants are added to the pipeline that transports the sewage, so that tiny oily particles are gradually formed under the action of flocculant adsorption and bridging Large alum flowers are oil residues;

[0020] (3) The sewage that h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com