Method for preparing rutile phase hypovanadic oxide powder

A technology of vanadium dioxide and rutile phase, which is applied in the direction of vanadium oxide, etc., can solve the problems that the rutile phase vanadium dioxide powder has not been seen yet, and achieve the effects of good product crystallinity, simple preparation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

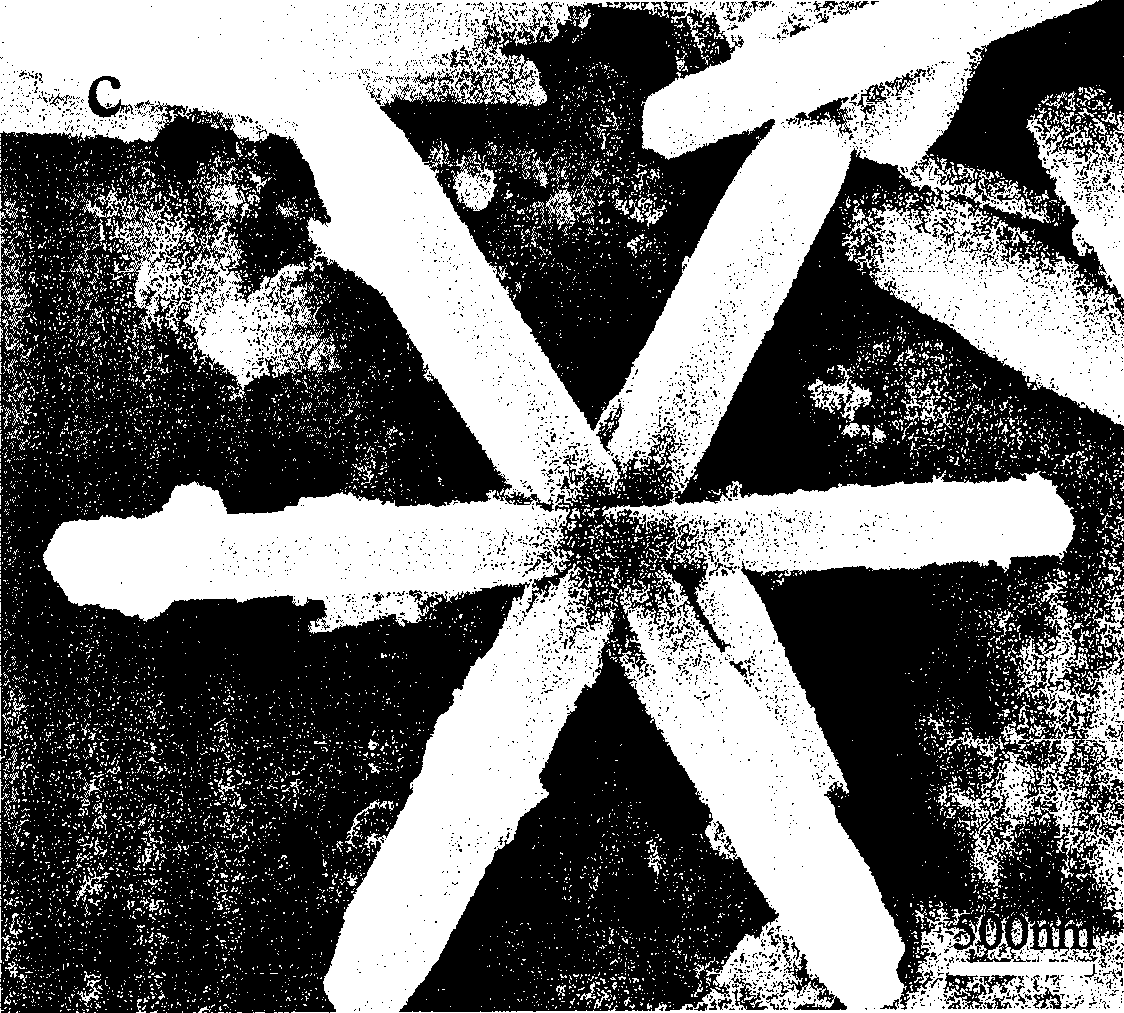

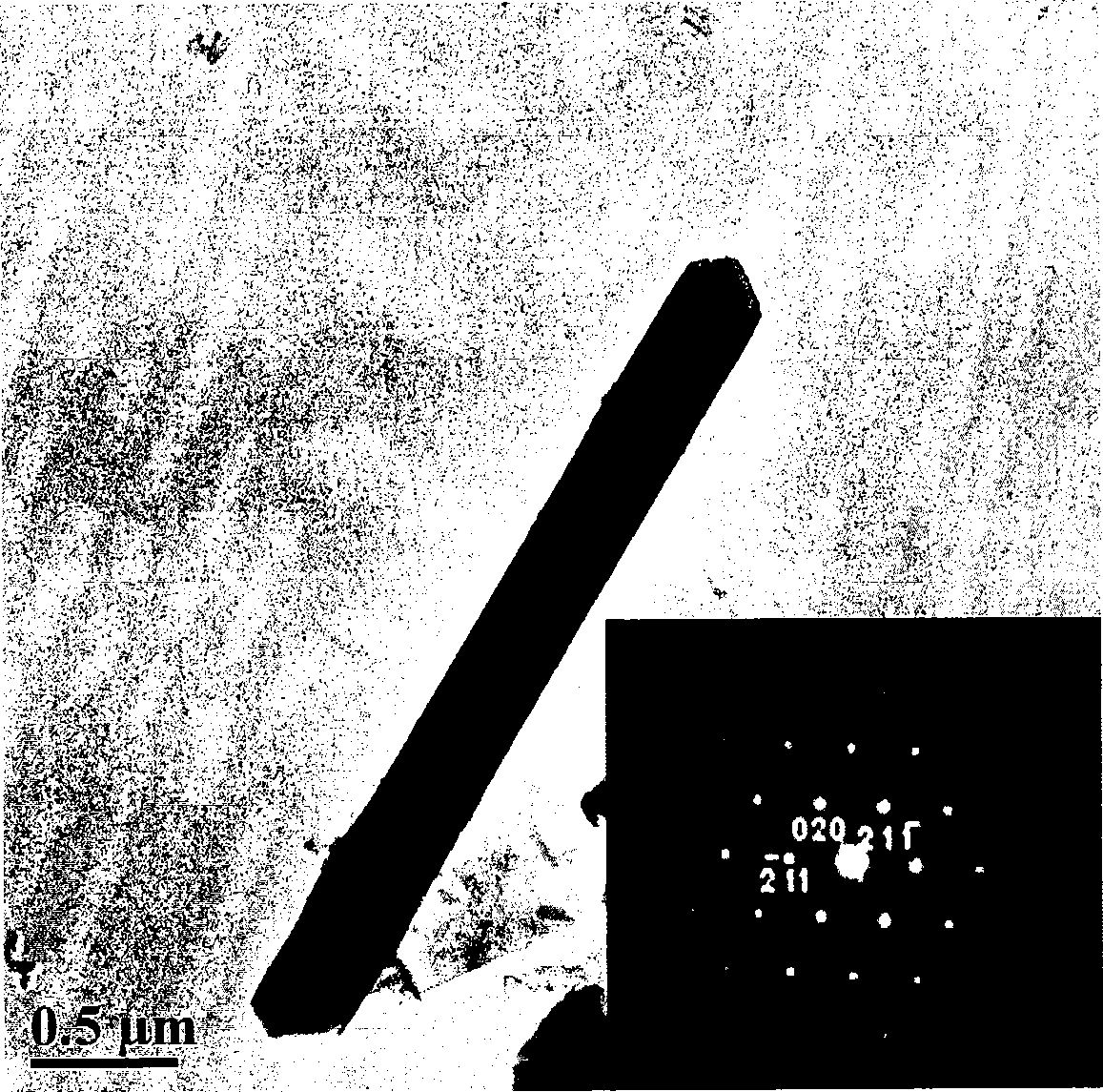

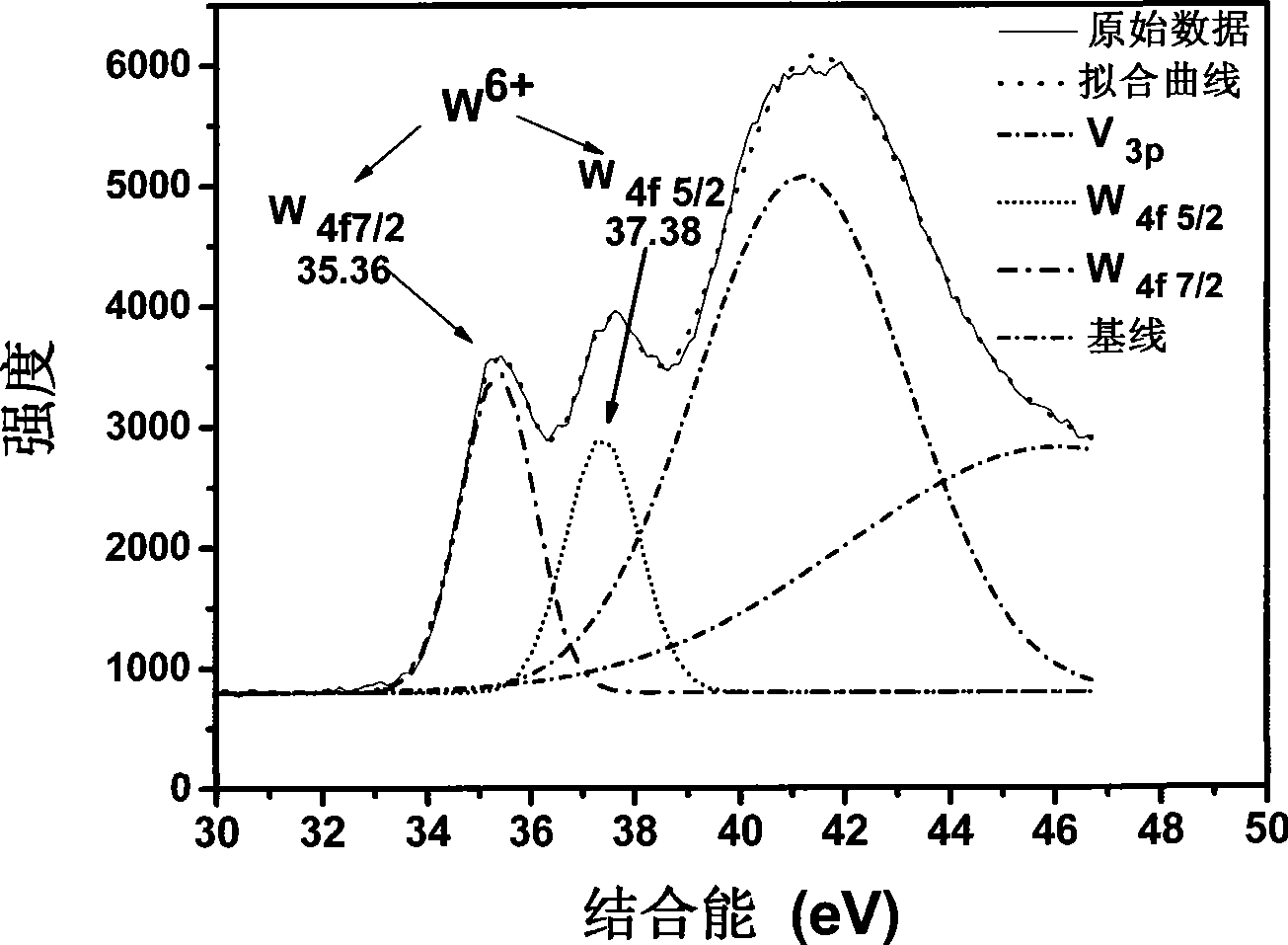

Image

Examples

Embodiment 1

[0029] Disperse the vanadium pentoxide powder in the oxalic acid solution, weigh white tungstic acid with a molar percentage of 1% vanadium ions, add the above solution to a 100ml polytetrafluoroethylene-lined hydrothermal kettle, and the filling amount is volume Percentage 50%, hydrothermal reaction at 240 degrees Celsius for 7 days, cooling, centrifugation, and drying in an oven at 70 degrees Celsius for 24 hours.

Embodiment 2

[0031] Disperse the vanadium pentoxide powder in the oxalic acid solution, weigh the sodium tungstate with a molar percentage of 8% vanadium ions, add the above solution into a 100ml polytetrafluoroethylene-lined hydrothermal kettle, and the filling volume is 85% , 240 degrees centigrade hydrothermal reaction for 7 days, then centrifuged after cooling, and dried in an oven at 70 degrees centigrade for 24 hours.

Embodiment 3

[0033] Configure the mixed solution of vanadyl sulfate and oxalic acid, take by weighing molybdic acid with a molar percentage of 4% of vanadium ions, the filling amount is 50% by volume, add the above solution to a 100ml polytetrafluoroethylene lined hydrothermal kettle, and the filling amount is volume Percentage 75%, hydrothermal reaction at 240°C for 3 days, cooling, centrifugation, and drying in an oven at 70°C for 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com