Glass ceramics and process for production thereof, process for producing sintered glass ceramics, process for producing complex, molded article having photocatalytic function, and hydrophilic molded article

A technology of glass-ceramics and manufacturing methods, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., capable of solving problems such as high manufacturing costs, insufficient photocatalytic properties, and photocatalytic property degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0395] A first embodiment of the method for producing glass ceramics is a method for producing glass ceramics characterized in that the raw material composition mixture is melted to form at least a part of the liquid phase, and then cooled and solidified. More specifically, predetermined starting materials are uniformly mixed, placed in a container made of platinum or a refractory, and heated and held at a predetermined temperature of 1250 or higher in an electric furnace to prepare a melt. Thereafter, the melt is poured into a mold and solidified to obtain the target crystallized glass. Here, formation and growth of crystal nuclei occur during the cooling of the melt. This method is effective, for example, when a large amount of desired crystal phases are precipitated and the state of the molten glass is relatively unstable.

[0396] Here, the liquid phase may be formed from at least one or more raw material compositions, and a decrease in the liquid phase formation temperat...

no. 2 Embodiment approach

[0399] A second embodiment of the method for producing glass ceramics is a method for producing glass ceramics comprising the following steps: a melting step of mixing raw materials to obtain the melt; a cooling step of cooling the melt to obtain a glass body; and a reheating step of raising the temperature of the above-mentioned glass body to a temperature range exceeding the glass transition temperature; and a crystallization step, maintaining the above-mentioned temperature within the above-mentioned temperature range to form crystals. Here, it is more preferable to include a recooling step, that is, to lower the above-mentioned temperature again after the crystallization step to obtain a crystal-dispersed glass.

[0400] (melting process)

[0401] The melting step is a step of mixing raw materials having the above-mentioned composition to obtain a melt thereof. More specifically, the raw materials are prepared so that the components of the glass-ceramics are within the sp...

Embodiment

[0542] Next, examples of the present invention are given below. It should be noted that the following examples are for illustrative purposes only, and the present invention is not limited to these examples.

[0543] [Formation of glass-ceramic moldings]

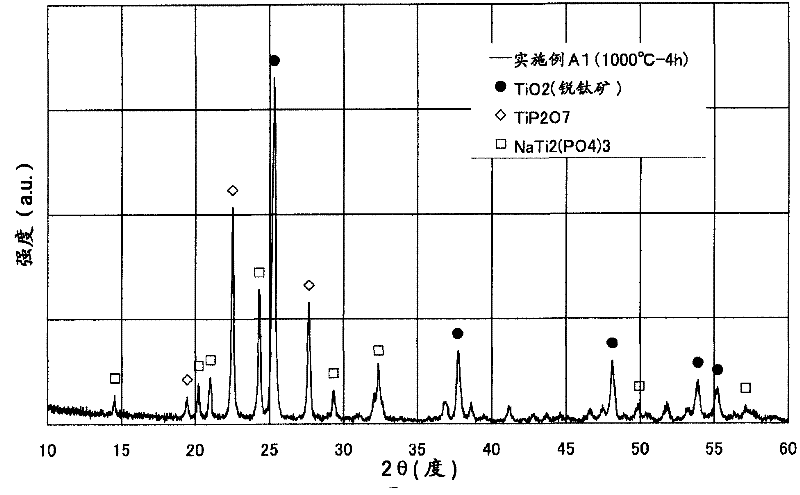

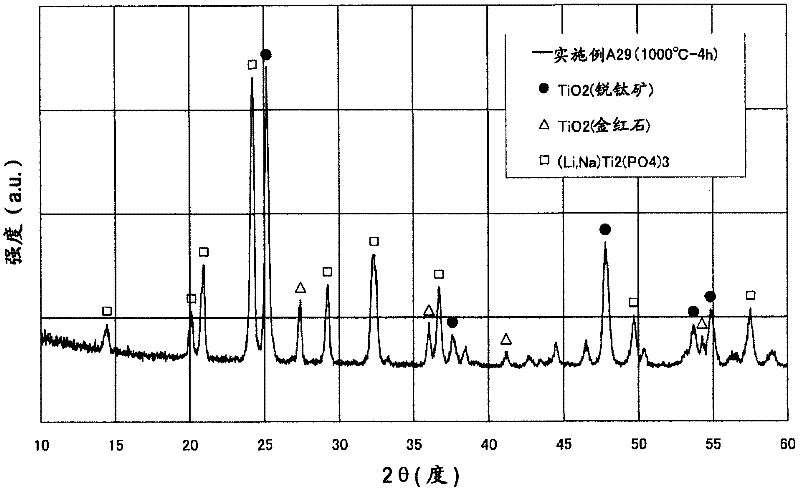

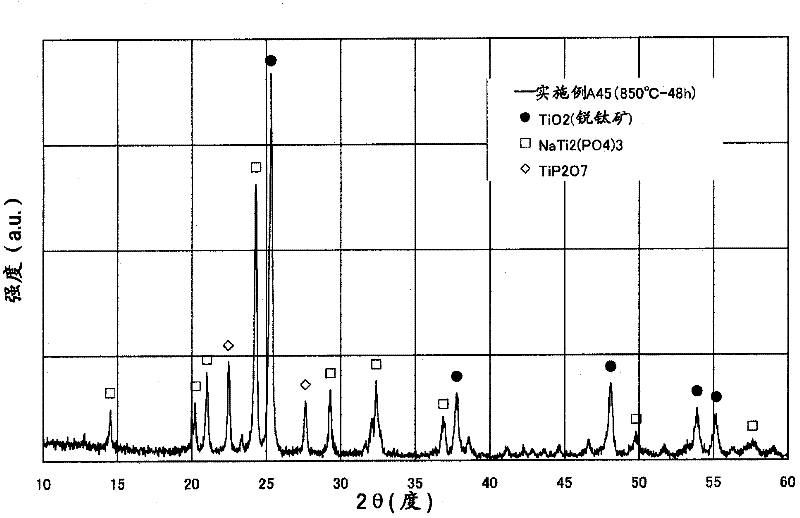

[0544] The composition and crystallization temperature of the glass-ceramic molded bodies of the examples (No.A1 to No.A122, No.B1 to No.B12) and comparative examples (No.a1, No.b1) of the present invention, and the above-mentioned crystallization temperature The types of precipitated crystal phases of the crystal glass molded body are shown in Tables 1 to 33.

[0545] The glass-ceramic molded bodies of Examples (No.A1-No.A122, No.B1-No.B12) and Comparative Examples (No.a1, No.b1) of the present invention are all selected as raw materials for each component. Oxides, hydroxides, carbonates, nitrates, fluorides, hydroxides, metaphosphoric acid compounds and other high-purity raw materials commonly used in glass, according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com