Cuprous oxide base antibacterial fibers and preparation method thereof

A cuprous oxide-based, antibacterial fiber technology, applied in the direction of one-component polyamide rayon, one-component polyester rayon, etc., can solve the problems of difficult cost control, low antibacterial activity, skin irritation or damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

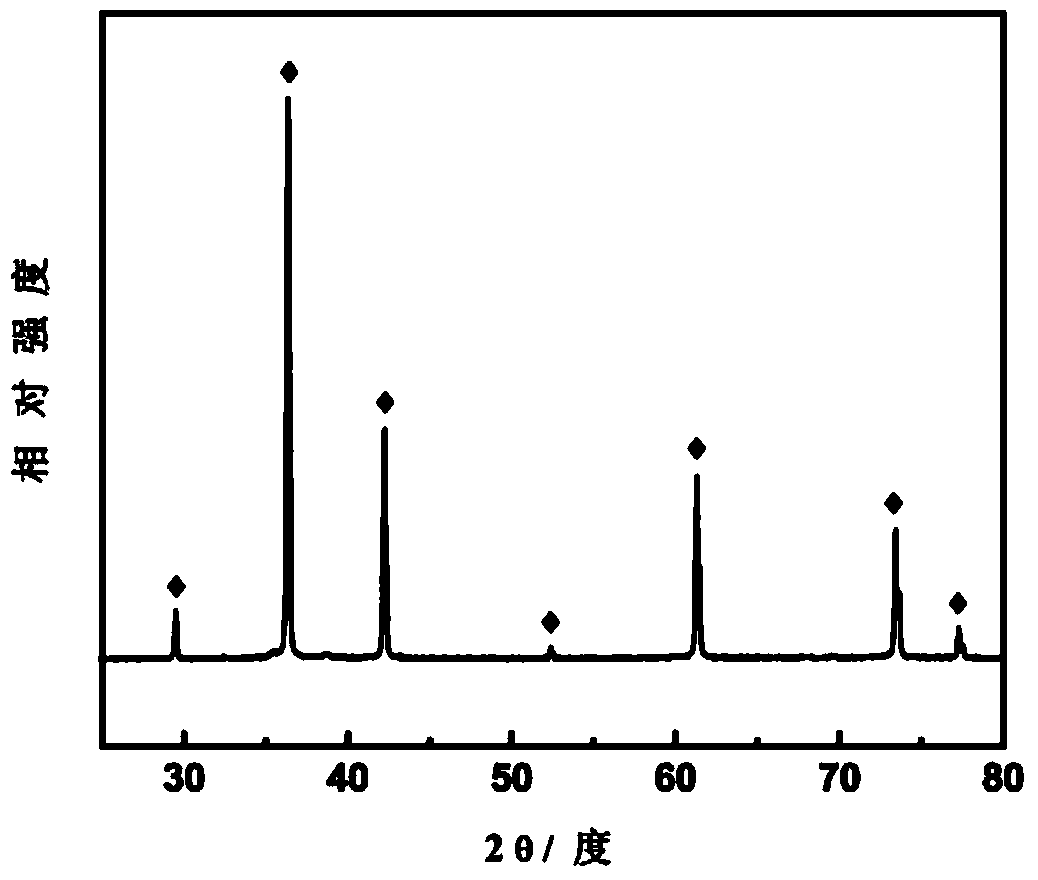

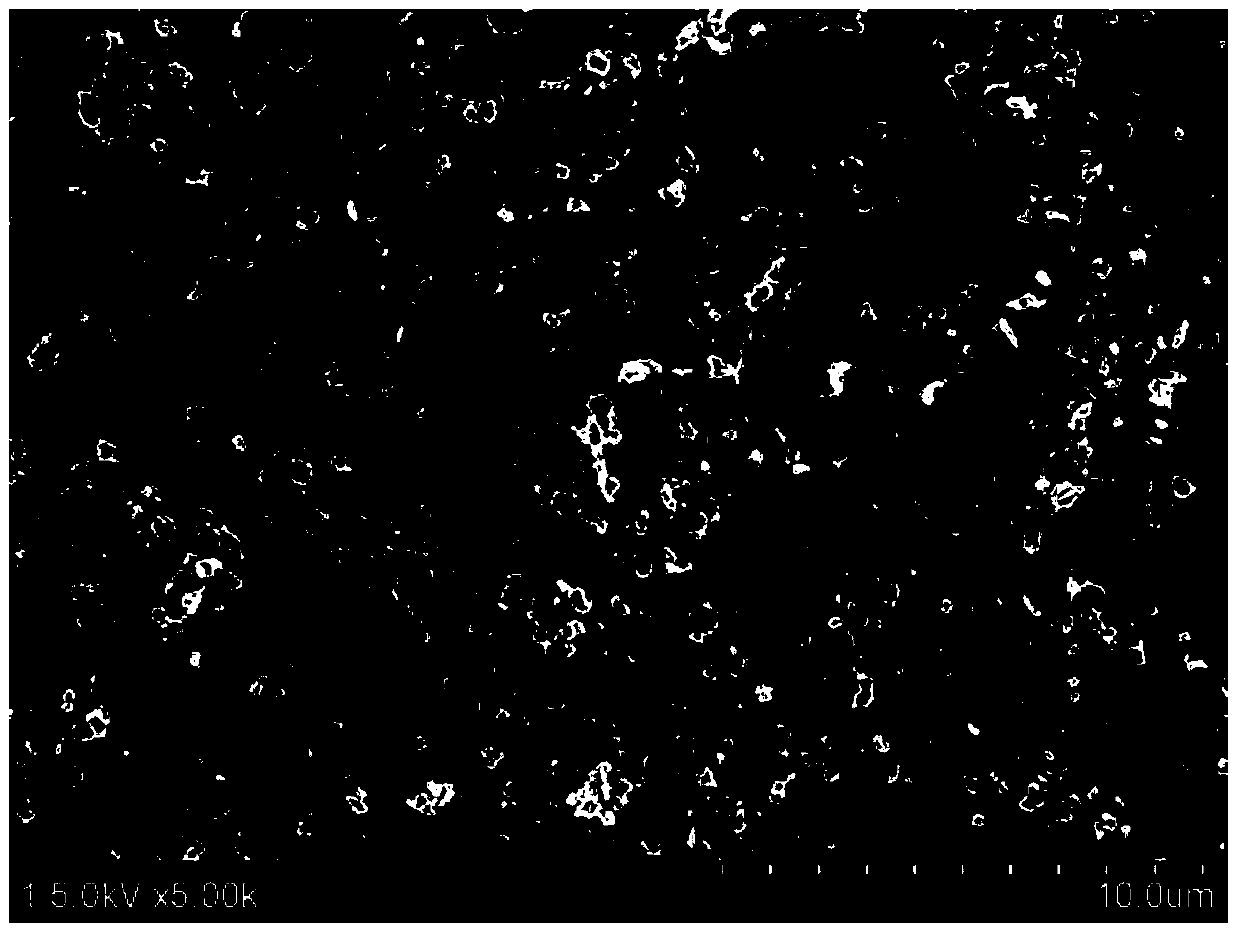

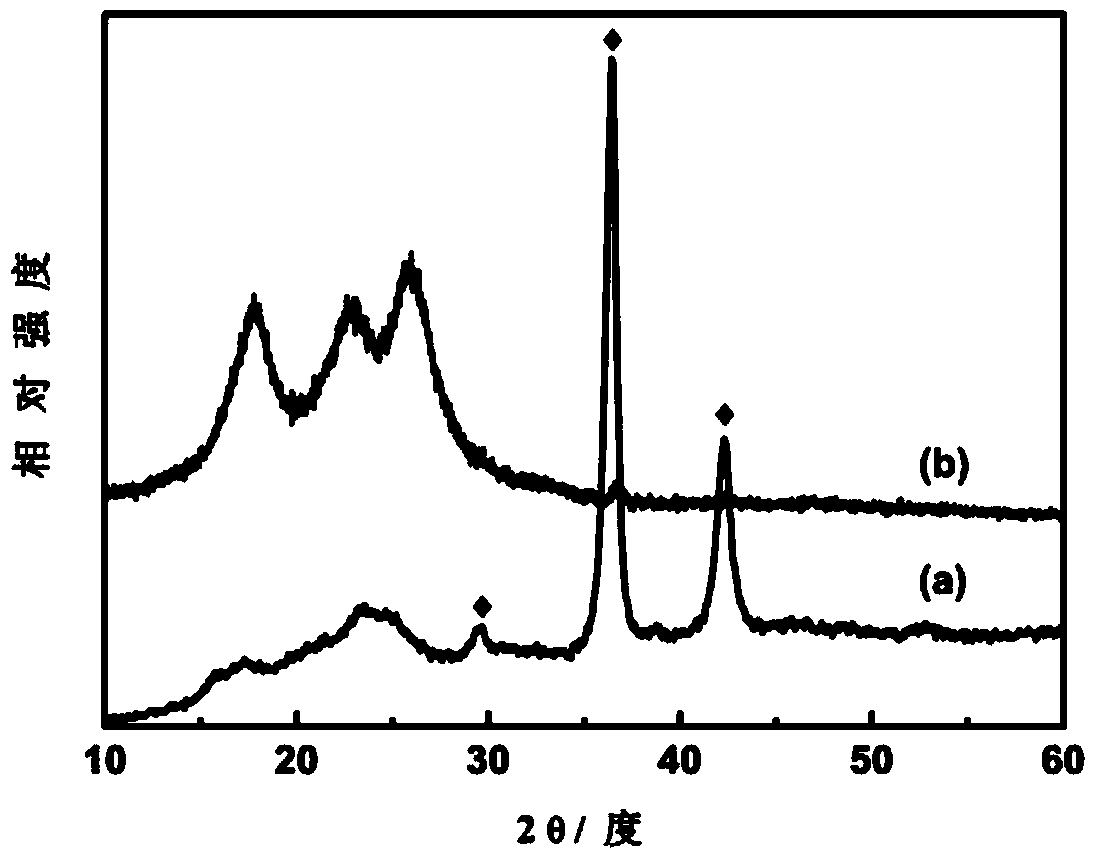

Method used

Image

Examples

Embodiment 1

[0015] After mixing 100g of modified cuprous oxide powder with 400g of polyester masterbatch, melt granulation to obtain cuprous oxide-based antibacterial polyester masterbatch, and mix 100g of the obtained antibacterial polyester masterbatch with 1900g of polyester masterbatch After uniformity, the cuprous oxide-based antibacterial polyester fiber is obtained by melt spinning at high speed.

Embodiment 2

[0017] After mixing 100g of modified cuprous oxide powder with 400g of polyester masterbatch, melt granulation to obtain cuprous oxide-based antibacterial polyester masterbatch, and mix 100g of the obtained antibacterial polyester masterbatch with 1000g of polyester masterbatch After uniformity, the cuprous oxide-based antibacterial polyester fiber is obtained by melt spinning at high speed.

Embodiment 3

[0019] Mix 100g of modified cuprous oxide powder with 400g of nylon masterbatch evenly, then melt and granulate to obtain cuprous oxide-based antibacterial nylon masterbatch, and mix 100g of the obtained antibacterial nylon masterbatch with 1900g of nylon masterbatch After uniformity, cuprous oxide-based antibacterial nylon fibers are obtained by melt spinning at high speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com