Sweet potato beverage preparation method

A sweet potato and beverage technology, applied in the field of food and beverage processing, can solve the problems of waste of resources, short processing cycle, high organic content, etc., and achieve the effect of increasing environmental protection load, increasing solid content, and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

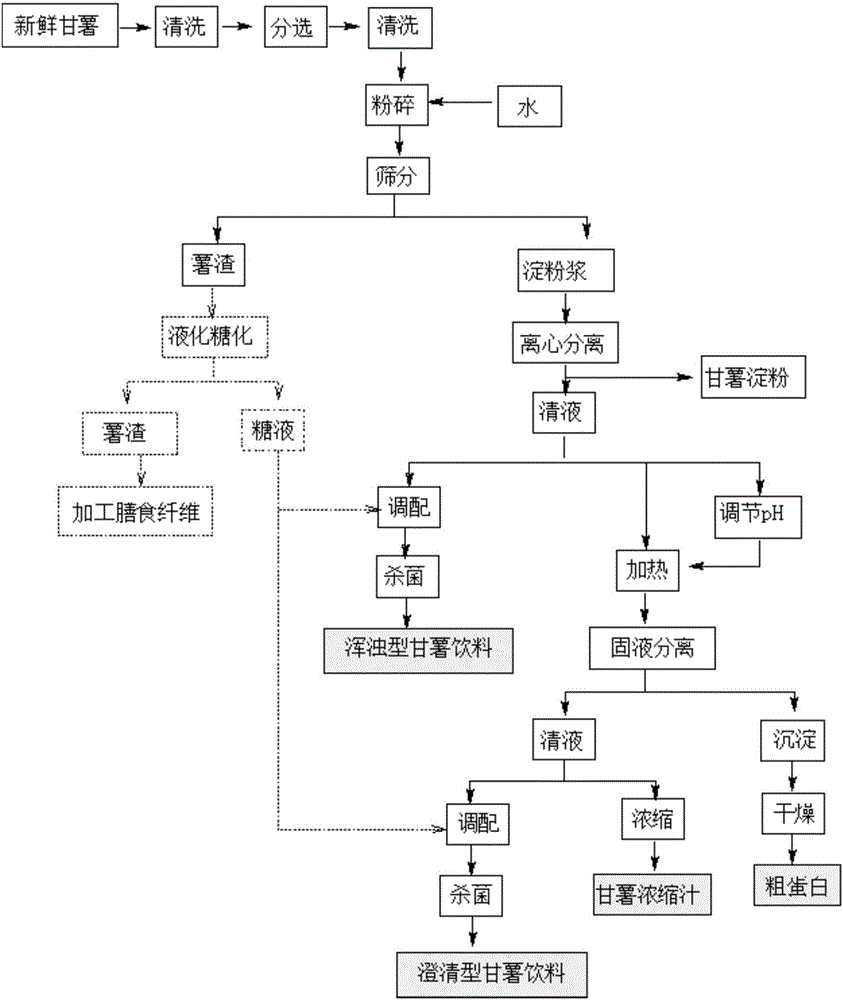

Image

Examples

Embodiment 1

[0039] 1 sweet potato processed

[0040] Select fresh and complete Jishu-21 sweet potatoes, after preliminary cleaning, then cut off the roots and pedicles, and clean them further; weigh 2kg of fresh sweet potatoes that have been processed, cut them into small pieces of about 1*1*1cm, add 3L of water, and use a beating Machine further crushed, filtered with a 200-mesh filter cloth, the filtered potato residue was washed once with 2L of water, filtered with a 200-mesh filter cloth, and the two filtrates were combined for starch separation. Add water to the potato residue after twice washing to adjust the appropriate concentration, and use it for the preparation of starch sugar and dietary fiber.

[0041] The obtained starch slurry was filtered and separated, stirred and mixed evenly, then centrifuged at 3000 rpm for 5 seconds, and the centrifuged sediment was washed with clear water, separated and dried to obtain 420 g of sweet potato starch. The centrifugal supernatant is use...

Embodiment 2

[0046] 1 sweet potato processed

[0047] Select fresh and complete Jishu-21 sweet potatoes, preliminarily clean them, then cut off the roots, and clean them further; weigh 2 kg of fresh sweet potatoes that have been processed, cut them into small pieces, add 3.5 L of water, and further smash them with a beater. Filter with a 200-mesh filter cloth, wash the obtained potato residue with 2L of water once, filter with a 200-mesh filter cloth, and combine the two filtrates for starch separation. Add water to the potato residue after twice washing to adjust the appropriate concentration, and use it for the preparation of starch sugar and dietary fiber.

[0048] The obtained starch slurry is filtered and separated, stirred and mixed evenly, then centrifuged at 3000 rpm for 5 seconds, and the centrifuged sediment is washed with clear water, separated and dried to obtain sweet potato starch. The centrifugal supernatant is used in sweet potato beverage processing.

[0049] 2 Sweet Pot...

Embodiment 3

[0053] 1 sweet potato processed

[0054] Select fresh and complete Jishu-21 sweet potatoes, after preliminary cleaning, then peeled, and further cleaned; weigh 2 kg of fresh sweet potatoes that have been processed, cut them into small pieces, add 4 L of water, further crush them with a beater, and filter them through a 200-mesh filter. Cloth filtration, the potato residue obtained by filtration is washed once with 2L of water, filtered with a 200-mesh filter cloth, and the two filtrates are combined for starch separation. Add water to the potato residue after twice washing to adjust the appropriate concentration, and use it for the preparation of starch sugar and dietary fiber.

[0055] The obtained starch slurry is filtered and separated, stirred and mixed evenly, then centrifuged at 3000 rpm for 5 seconds, and the centrifuged sediment is washed with clear water, separated and dried to obtain sweet potato starch. The centrifugal supernatant is used in sweet potato beverage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com