Method for synthesizing OMS-2 manganese oxide octahedral molecular sieve

An octahedral molecular sieve, OMS-2 technology, applied in molecular sieve compounds, chemical instruments and methods, manganese oxide/manganese hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

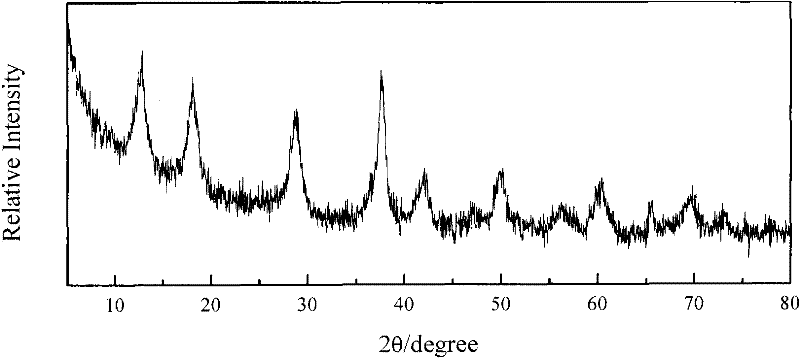

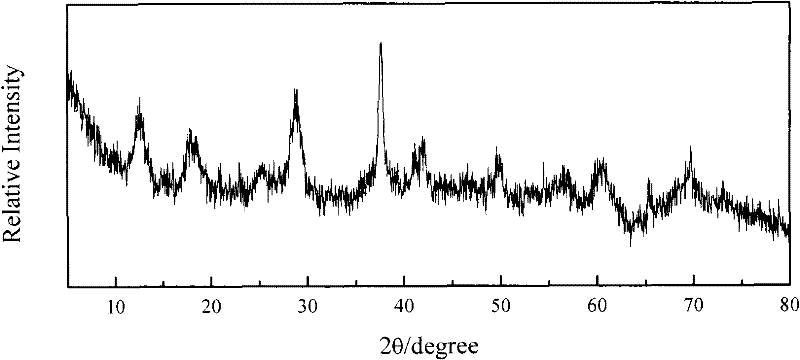

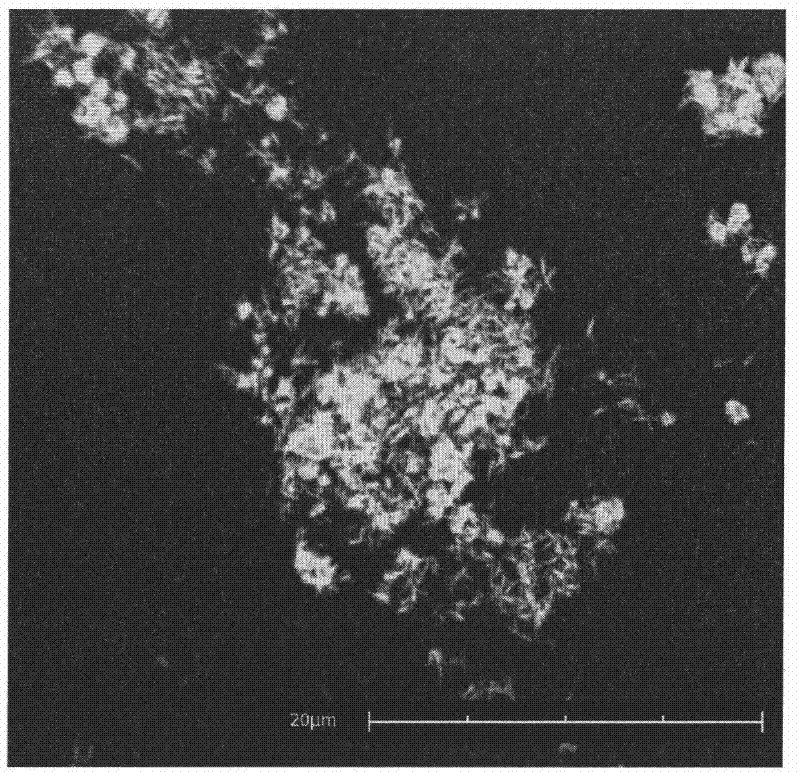

Image

Examples

Embodiment 1

[0030] Put 30.00g of 1-methyl-3-butylimidazole bromide in a 250mL two-necked flask, and add 0.79g of KMnO 4 . Continue stirring until the reactants are well mixed.

[0031] The reaction mixture was transferred to an oven at 150° C., and allowed to stand at a constant temperature for crystallization for 10 h.

[0032] The reaction mixture was poured into ethanol, sonicated and filtered. The filter cake was washed with ethanol. The product was dried overnight in an oven at 110°C. The obtained product is OMS-2 manganese oxide octahedral molecular sieve.

Embodiment 2

[0034] Put 65.00g of 1-methyl-3-ethylimidazolium bromide ionic liquid in a 250mL two-necked bottle, and add 0.79g of KMnO 4 . Continue stirring until the reactants are well mixed.

[0035] The two-neck bottle containing the reaction mixture was transferred to a MARS5 microwave reactor, and the reaction temperature was measured using a RPT-300plus temperature sensor. Set the reaction temperature to 120°C and the heating time to 20min. Stand at constant temperature for 30min to crystallize.

[0036] The reaction mixture was poured into ethanol, sonicated and filtered. The filter cake was washed with ethanol. The product was dried overnight in an oven at 110°C. The obtained product is OMS-2 manganese oxide octahedral molecular sieve.

Embodiment 3

[0038] Put 20.00g of 1,2-dimethyl bromide, 3-ethylimidazolium ionic liquid in a 250mL two-necked flask, and add 0.34g of KNO to it under vigorous stirring at 70°C 3 , 2.37g KMnO 4 . Continue stirring until the reactants are well mixed.

[0039] The reaction mixture was transferred to an oven at 150° C., and left at constant temperature for crystallization for 24 h.

[0040] The reaction mixture was poured into ethanol, sonicated and filtered. The filter cake was washed with ethanol. The product was dried overnight in an oven at 110°C. The obtained product is OMS-2 manganese oxide octahedral molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com