Production method of potassium salt

A production method and technology of potassium salt, applied in the field of potassium chloride, can solve problems such as reducing the grade of minerals in mining areas, endangering salt lake resources, and destroying the balance of water and salt systems, so as to relieve the pressure on water resources, reduce non-point source pollution, The effect of reducing the amount of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

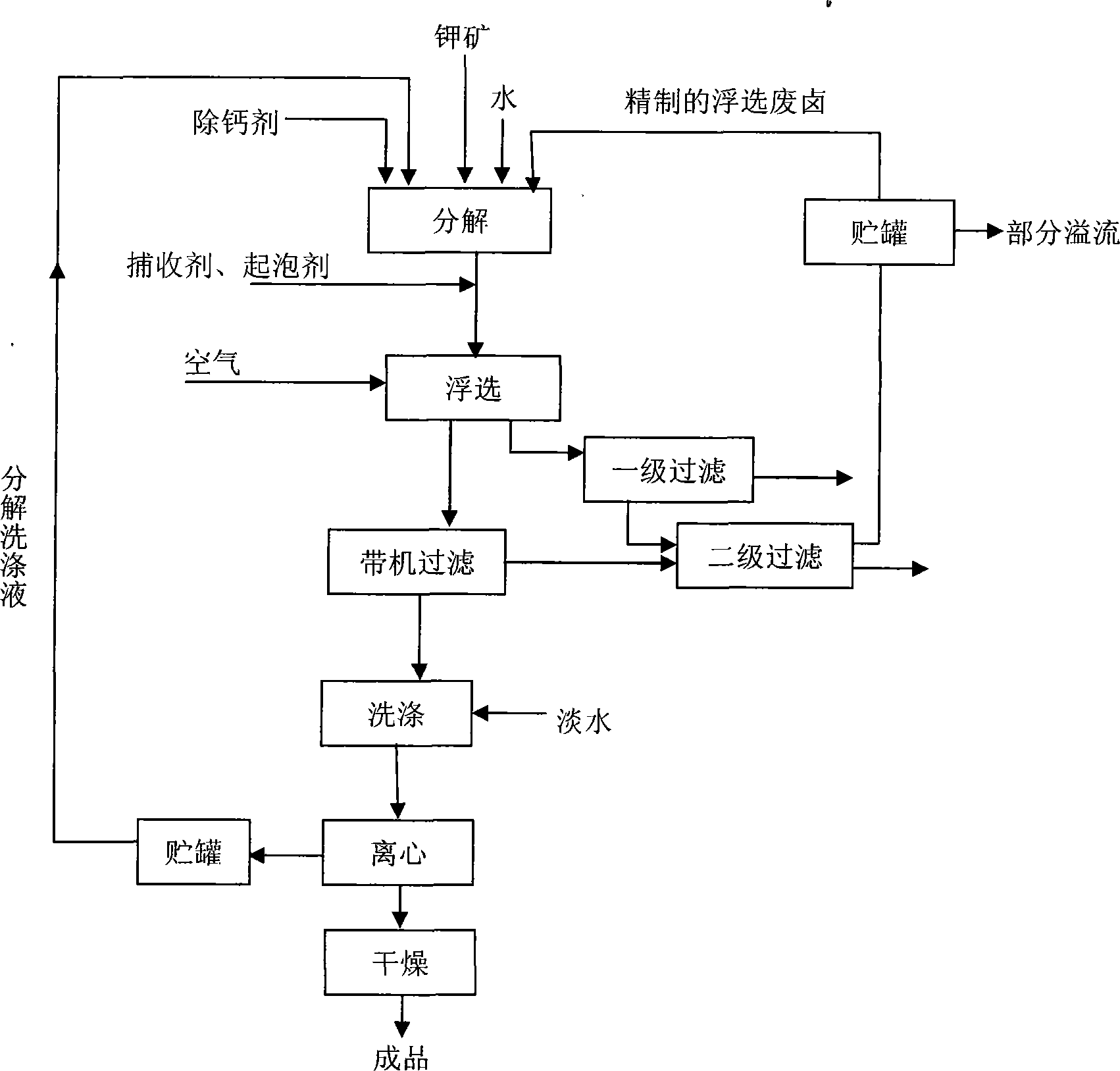

[0024] according to figure 1 A kind of potassium salt production process shown in the experiment is carried out. The experimental raw material comes from Qinghai Chaerhan Salt Lake. The production experiment steps:

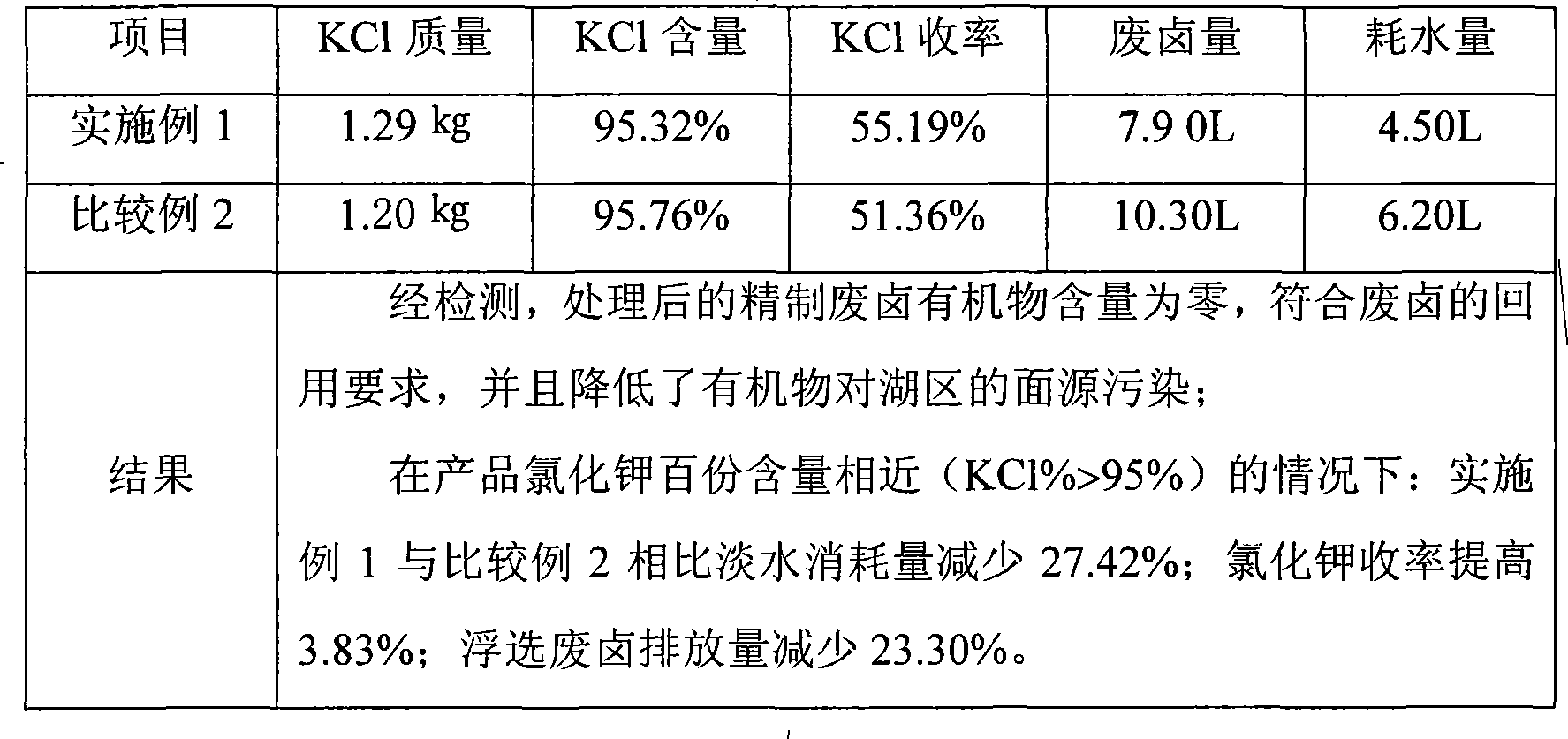

[0025] 1. Weigh 10kg raw carnallite (KCl: 19.07%, NaCl: 18.32%, MgCl 2 : 27.51%, CaSO 4 : 0.42%) and put 3.20L of fresh water into the decomposition tank, and add 5‰ aqueous solution prepared with 500mg carboxymethyl cellulose into the decomposition tank to remove impurities such as calcium sulfate and clay in the raw material carnallite , and measure 1.60L decomposed washing solution (KCl: 11.06%, NaCl: 2.04%, MgCl 2 : 1.11%, CaSO 4 : 0.35%, ρ=1.26g / ml) and 3.20L of refined flotation waste halogen (KCl: 4.22%, NaCl: 4.84%, MgCl 2 : 18.06%, CaSO 4 : 0.14%, ρ=1.40g / ml) adds in the decomposition tank, and stirring speed is 320rpm, and raw material generates containing potassium chloride and sodium chloride crystal particle after decomposing 30 minutes at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com