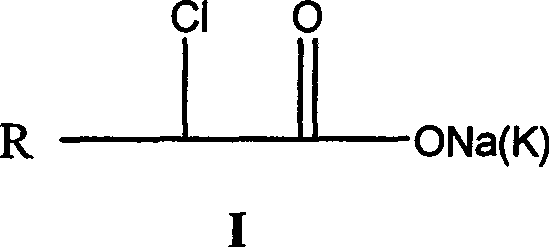

Chloro-sodium soap/sylvite flotation agent and method for producing the same

A technology of chlorinated sodium fatty acid and sodium fatty acid, which is applied in the preparation of carboxylate, flotation, solid separation, etc., can solve the problem that the price of phosphate concentrate is not competitive, the cost of waste liquid treatment is difficult, and the amount of flotation agent increases, etc. problems, to achieve the effect of improving surface activity, increasing solubility, and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

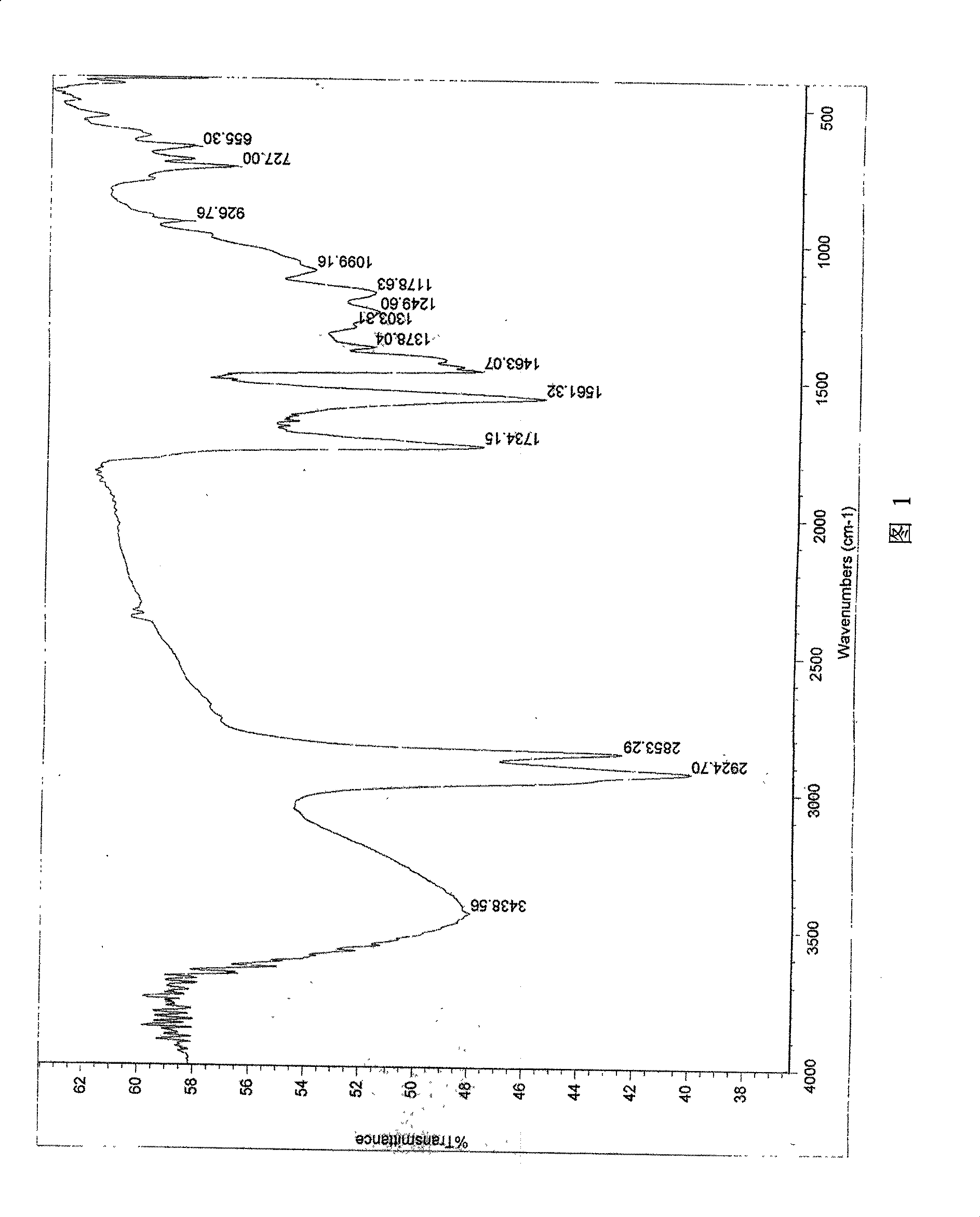

Image

Examples

Embodiment 1

[0023] Add 0.3 mol of rapeseed oil to a 1L beaker, mechanically stir and heat, add 1.2 mol (15 mol / L) of NaOH solution at 80°C, and keep warm at 90-100°C until a small amount of product is taken in cold water without oily flowers to obtain a saponified product , add 100ml of 80°C water and 0.1mol of NaOH solution and continue to keep warm for half an hour. Add 1.5 mol (12 mol / L) of concentrated sulfuric acid to the product at room temperature, heat and mechanically stir at 90-100°C for 3 hours, let stand to separate the liquid, take the upper oily matter, wash it twice at 80°C, and dry to obtain anhydrous fatty acid;

[0024] The obtained anhydrous fatty acid is placed in a 1L three-necked flask, the catalyst thionyl chloride is added, heated to 90-100°C, and 3 mol of chlorine gas (0.1L / min) is passed through. After the reaction is completed, the chlorinated fatty acid is obtained, and 2 mol of NaOH solution is added thereto. Keep warm and reflux for 2 hours, add NaCl and let ...

Embodiment 2

[0026] Add 0.6 mol of rapeseed oil to a 2L beaker, mechanically stir and heat, add 2 mol (12 mol / L) of NaOH solution at 90°C, and keep warm at 90-100°C until a small amount of product is taken in cold water without oily flowers to obtain saponified product. Add 200ml of 80°C water and 0.6mol of NaOH solution and continue to keep warm for half an hour, add NaCl and let it stand for salting out for 5 hours, take the upper saponified product and wash it with water (the amount of water should not be too much to produce jelly) to obtain the saponified product, the obtained saponified product Add 2.7 mol (8 mol / L) of concentrated sulfuric acid at room temperature, heat and mechanically stir at 90-100°C for 3 hours, let stand to separate the liquid, take the upper oily matter, wash it twice with water at 70-90°C, and dry to obtain anhydrous fatty acid;

[0027] The obtained anhydrous fatty acid is placed in a 2L three-necked flask, a catalyst is added, and the temperature is heated to...

Embodiment 3

[0029] Add 0.6 mol of rapeseed oil to a 2L beaker, mechanically stir and heat, add 2 mol of KOH solution (18mol / L) at 90°C, and keep warm at 90-100°C until a small amount of product is taken in cold water without oily flowers to obtain a saponified product. Add 200ml of 80°C water and 0.3mol of KOH solution and continue to keep warm for half an hour, add NaCl and let it stand for salting out for 5 hours, take the saponified product in the upper layer and wash it with water (the amount of water should not be too much to produce jelly) to obtain the saponified product, the obtained saponified product Add 3.2 mol (10 mol / L) of concentrated sulfuric acid at room temperature, heat and mechanically stir at 90-100°C for 3 hours, let stand to separate the liquid, take the upper oily matter, wash it twice at 70-90°C, and dry to obtain anhydrous fatty acid;

[0030] The obtained anhydrous fatty acid is placed in a 2L three-necked flask, a catalyst is added, and the temperature is heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com