Flame-retardant potassium ion battery electrolyte and preparation method thereof

A potassium ion and flame retardant technology, which is applied in the field of flame retardant potassium ion battery electrolyte and its preparation, can solve the problems of flammability, low boiling point and easy volatility of batteries, and achieves improved safety, wide application in the market, good The effect of flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

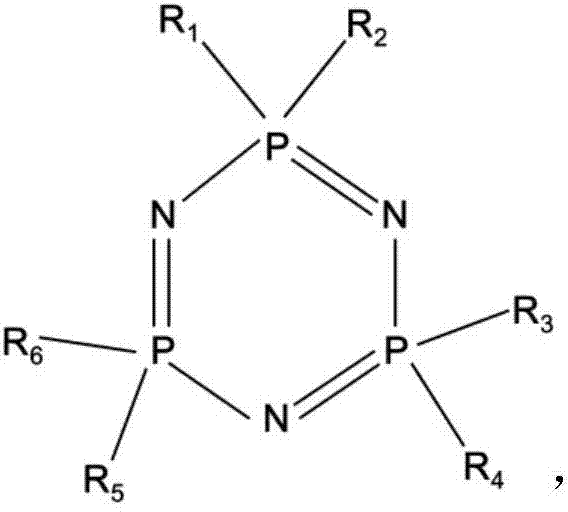

[0046] Preparation of siloxyfluorocyclotriphosphazene:

[0047] Dissolve 49.8g of hexafluorocyclotriphosphazene crystals in 200ml of tetrahydrofuran to form a hexafluorocyclotriphosphazene solution, add 12.9g of potassium trimethylsiliconate to the solution, stir until uniform, and react at 10°C for 20h , After filtration and vacuum distillation, the phosphazene derivative siloxyfluorocyclotriphosphazene was obtained.

Embodiment 2

[0049] The preparation process of methoxy pentafluorocyclotriphosphazene:

[0050] Methoxypentachlorocyclotriphosphazene was added to 200g of acetonitrile with constant stirring, and 110g of NaF was added. After a fluorination reaction at 60°C for 4 hours, methoxypentafluorocyclotriphosphazene was obtained by distillation.

Embodiment 3

[0052] The preparation process of triacetylbutanol-triethoxycyclotriphosphazene:

[0053] Put 49.8g of hexachlorocyclotriphosphazene crystals and hexane in a 500ml three-neck flask equipped with a stirrer, thermometer, and back distillation condenser, stir until it dissolves evenly, and react with 180g of sodium acetobutoxide at a temperature of 60°C 4 hours, then reacted with 40g sodium ethylate in 200 ethane for 4 hours, distilled, and refined to obtain a phosphazene derivative: triacetylbutanol-triethoxycyclotriphosphazene.

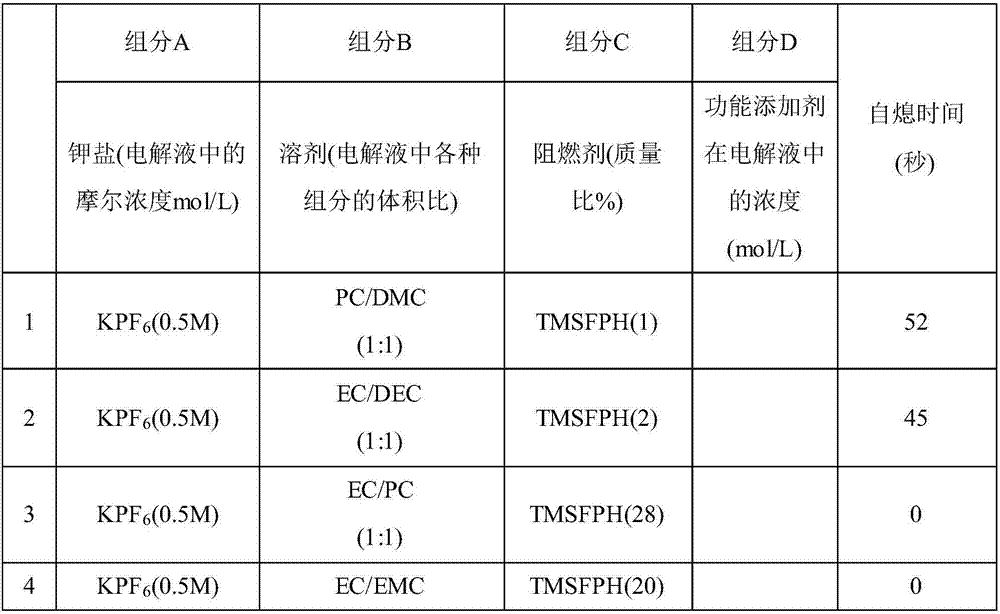

[0054] The present invention lists the compositions of 32 kinds of flame-retardant potassium-ion battery electrolytes and the test data of the self-extinguishing time of each flame-retardant potassium-ion battery electrolyte in tabular form, as shown in Table 1 below. The preparation method of the flame-retardant potassium ion battery electrolyte is as follows: the flame retardant uses 4A potassium molecular sieve to remove water for 40-55 hours, disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com