Garbage leachate reverse-osmosis concentrate treatment method

A technology for reverse osmosis concentrate and landfill leachate, which is applied in the treatment of polluted groundwater/leachate, chemical instruments and methods, multi-stage treatment of water/sewage, etc. , large amount of dosing and other problems, to achieve the effect of reducing investment and operating costs, improving concentration and crystallization efficiency, and reducing scale inhibition costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

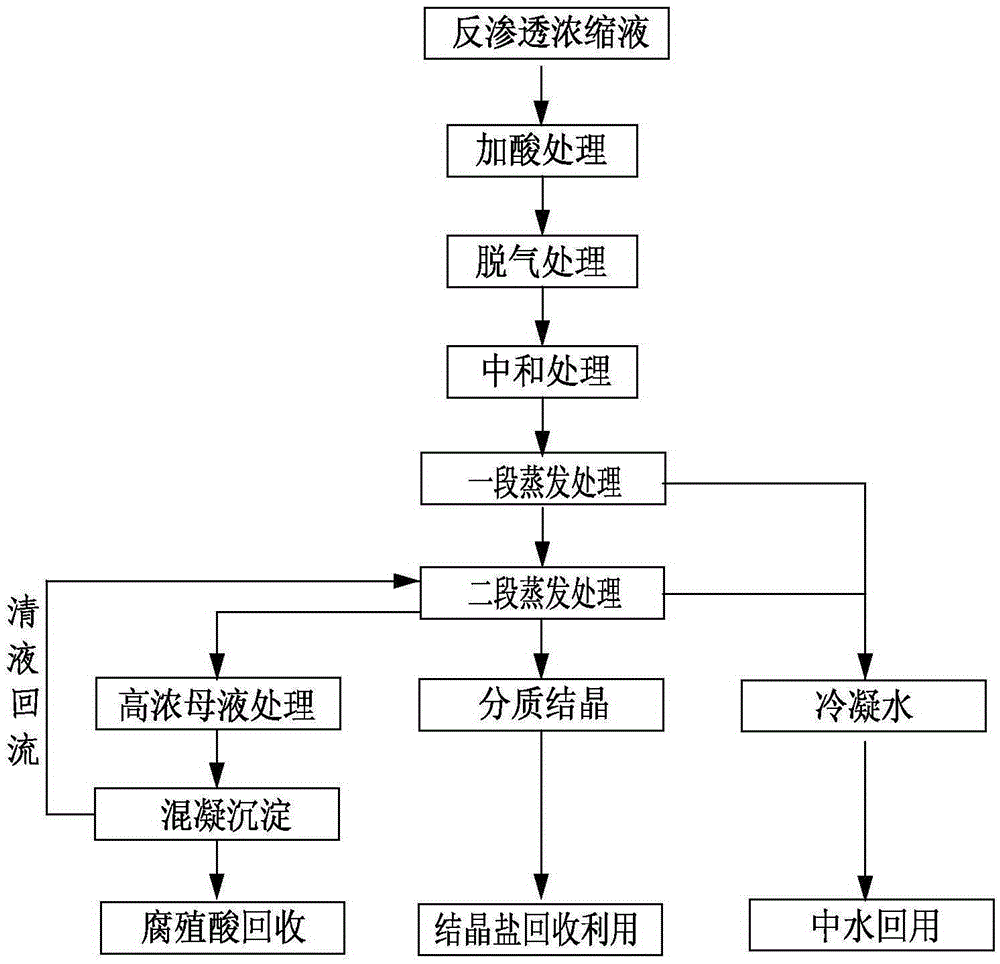

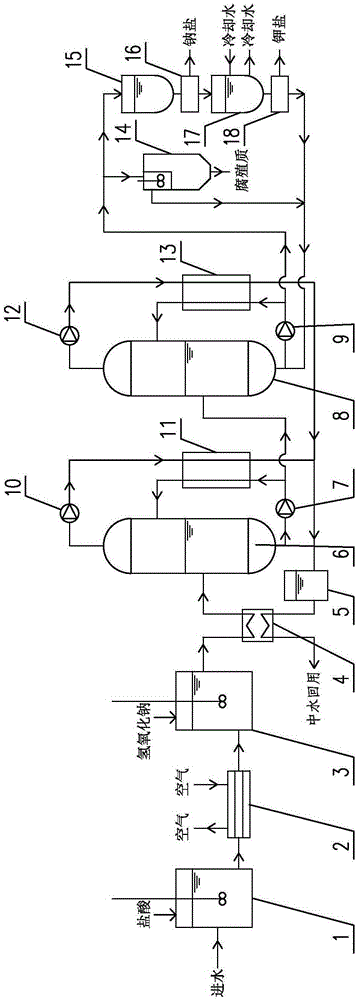

[0023] See figure 1 , 2 Shown, landfill leachate reverse osmosis concentrated solution processing method of the present invention, carry out according to the following steps,

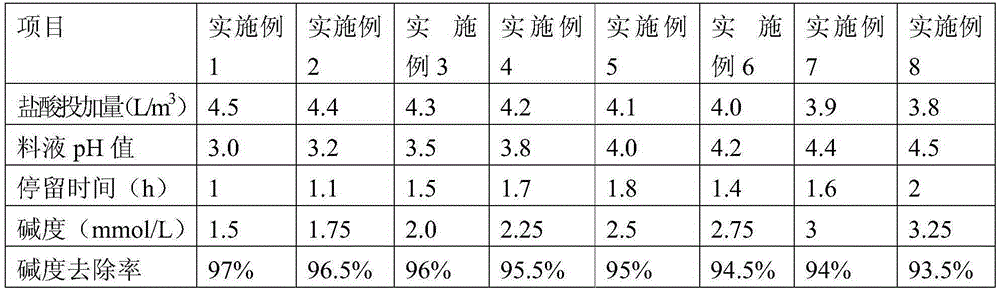

[0024] (1) Acid addition treatment: Add the reverse osmosis concentrated solution into the acid adding pool 1, add hydrochloric acid to the reverse osmosis concentrated solution, mix and stir, adjust the pH value of the reverse osmosis concentrated solution to 3.0-4.5, and the residence time is 1 After -2h, treat the reverse osmosis concentrated solution into a feed solution containing calcium and magnesium salts and carbon dioxide gas, and use the concentrated solution to add acid to release carbon dioxide gas to reduce the alkalinity of the concentrated solution, so that the formed calcium and magnesium salts are difficult to scale. The following reactions take place in Pool 1:

[0025] Ca(HCO 3 ) 2 +HCl→CaCl 2 +CO 2 ↑+H 2 o

[0026] Mg(HCO 3 ) 2 +HCl→MgCl 2 +CO 2 ↑+H 2 o

[0027] After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com