Method for preparing lithium salt ore from plateau sulfate type salt lake brine

一种硫酸盐型、盐湖卤水的技术,应用在锂硫酸盐/亚硫酸盐、可持续制造/加工、气候可持续性等方向,能够解决自然环境恶劣、影响盐湖卤水开发利用、没有化工企业等问题,达到降低生产成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0029] The present invention utilizes plateau sulphate type salt lake brine to prepare the method concrete step-by-step description of lithium salt ore as follows:

[0030] Step 1: Import the raw brine of the plateau sulfate-type salt lake into the pre-drying tank for evaporation, and adjust the content of sodium ions and sulfate ions in the brine by controlling the inflow of brine, so that the concentration of sodium ions in the brine reaches saturation with sodium chloride State, and the concentration of sulfate ions is 5g / L~25g / L.

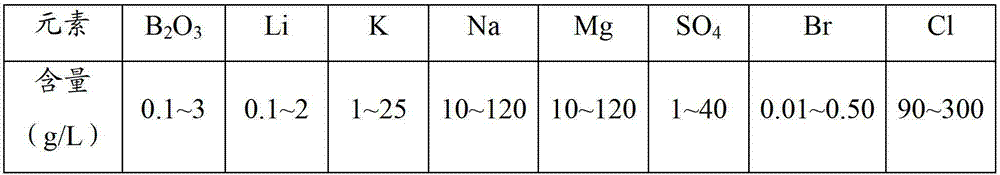

[0031] The sulfate-type salt lake brine used in the present invention can be any plateau ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elevation | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com