Forming method and forming system for straw pellets

A technology for particle forming and straw, which is applied in the field of straw particle forming method and particle forming system, can solve the problems of poor quality of straw briquetting, low briquetting efficiency, lack of a set of system for straw briquetting, etc. The effect of raising the selling price and beautiful shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0041] A method for forming straw granules, comprising the following steps:

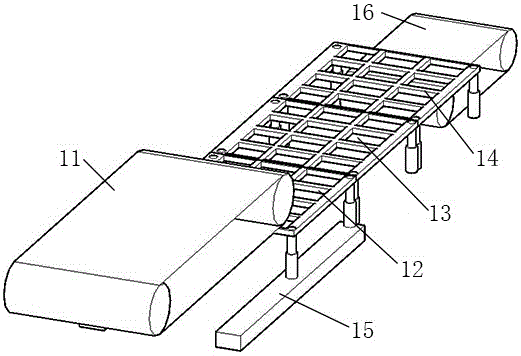

[0042] 1) Through the straw input device 11 in the straw cleaning device, the first straw cleaning frame 12, the second straw cleaning frame 13, the third straw cleaning frame 14, the straw output device 16, the moving mechanism 15 and the shaking parts, the straw in the straw Removal of impurities such as soil clods and gravel;

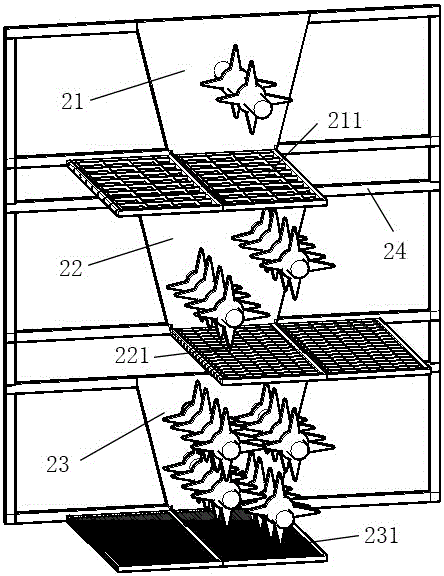

[0043] 2) Cut all the straw through the second straw input device, the second straw output device, and the first cutting box 21, the second cutting box 22, and the third cutting box 23 arranged in sequence from top to bottom in the straw crushing device into small pieces of straw below 5mm;

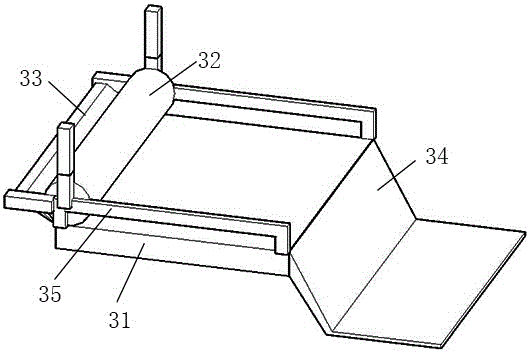

[0044] 3) Clean the dust in the straw section and drain the water in the straw section through the stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com