Straw briquetting machine

A technology of straw briquetting machine and pressing wheel, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as uneven distribution of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

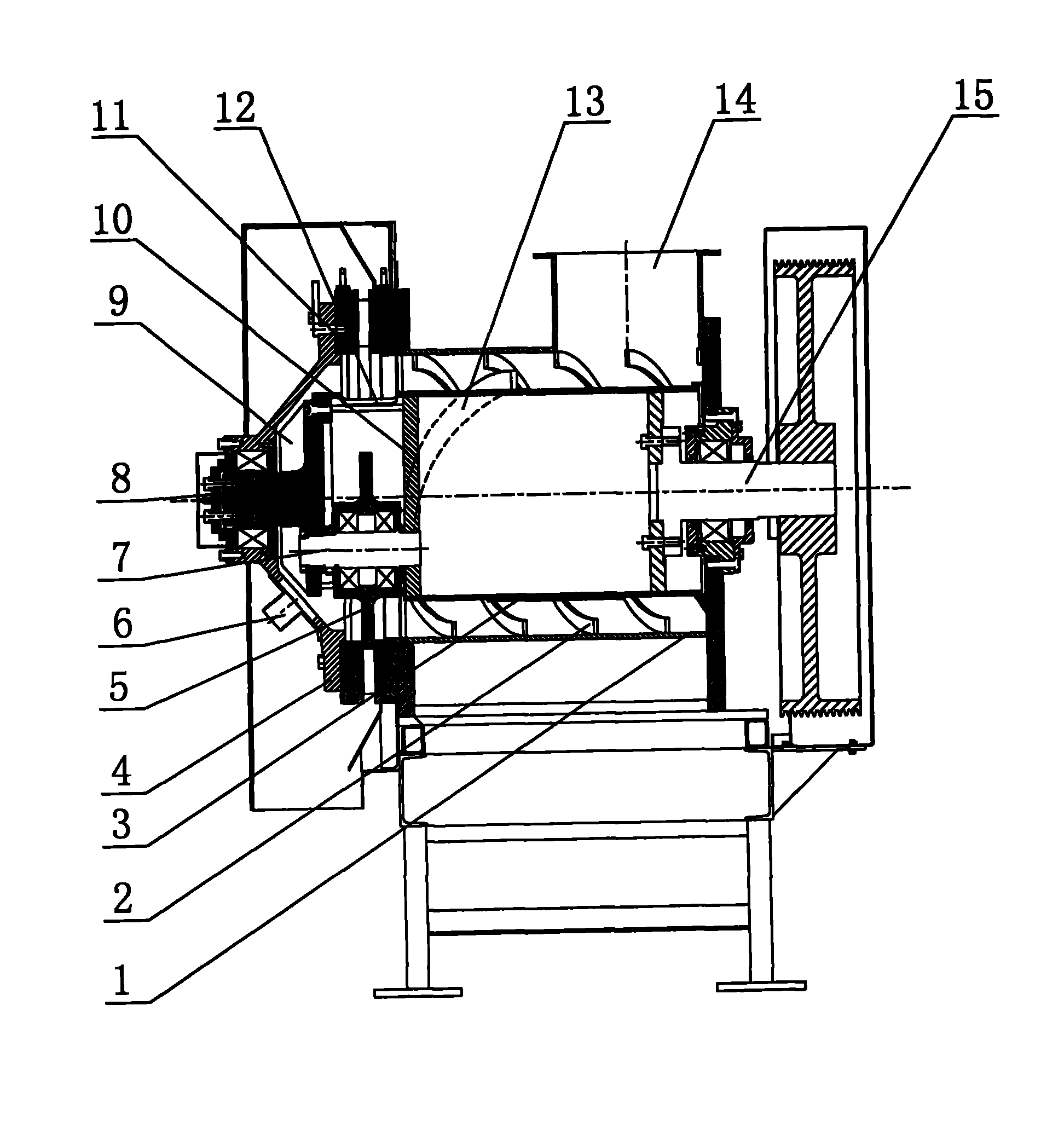

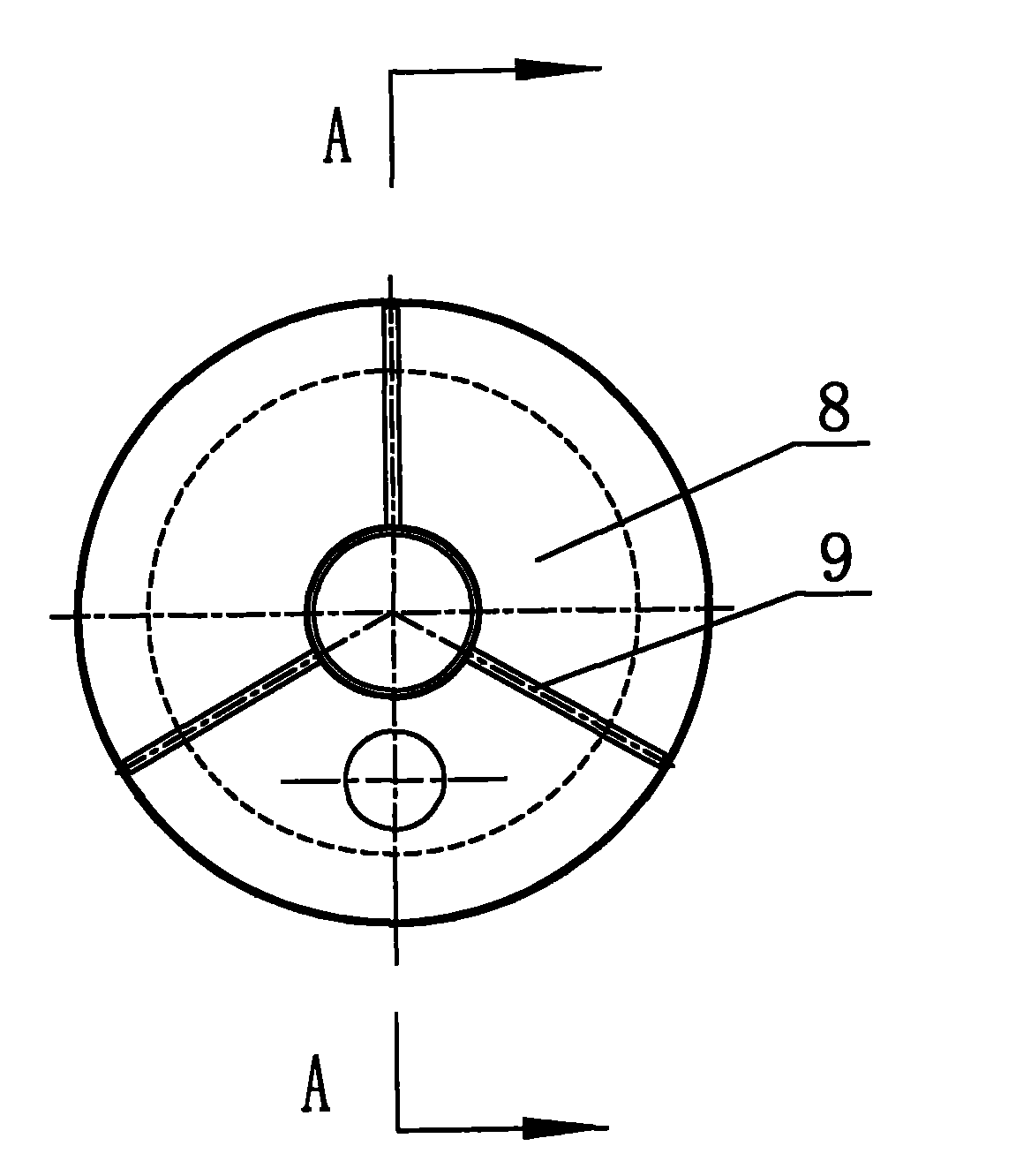

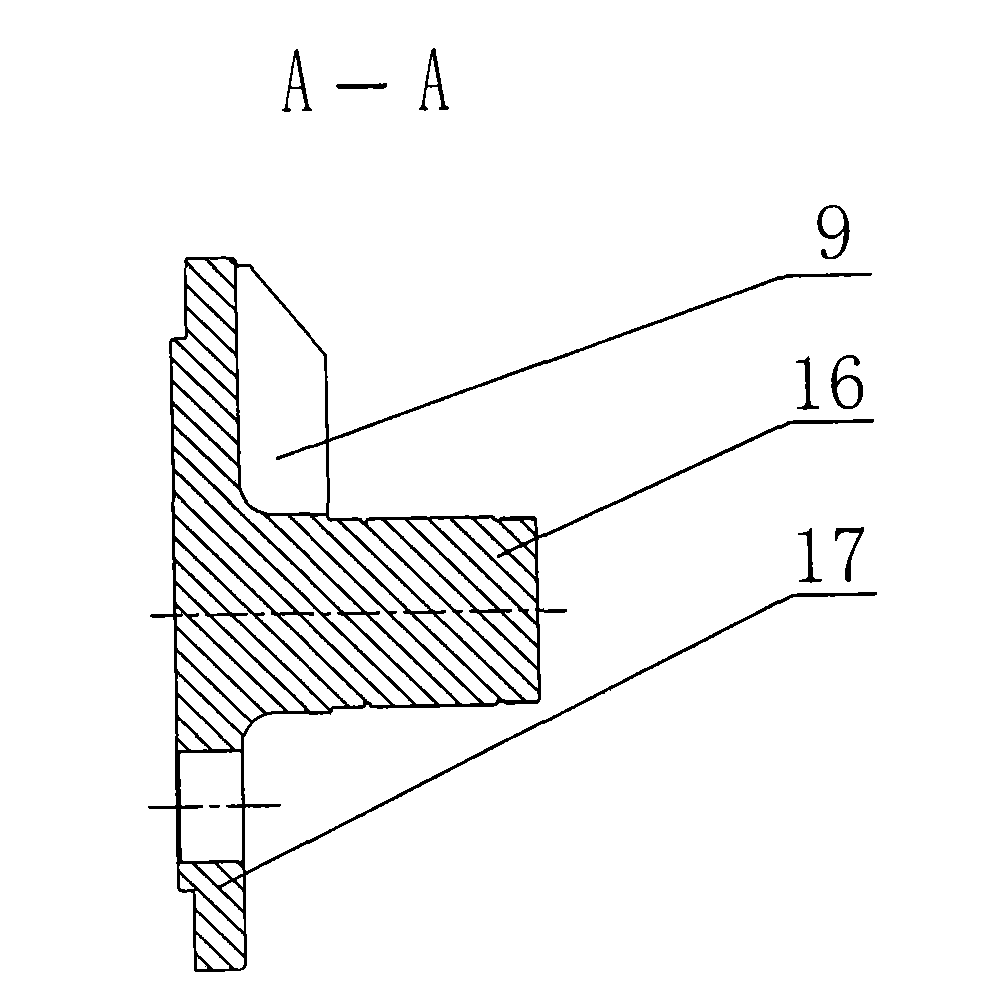

[0016] As shown in the figure, it is a straw briquetting machine, which includes an outer cylinder 1 with a feeding port 14 above one end, and an annular template assembly 11 is fixed on the other end of the outer cylinder 1, and the module assembly 11 includes an annular Front end plate 18 and back splint 21, be provided with some monolithic modules 20 between front end plate 18 and rear splint 21, monolithic module 20 is distributed in the form of ring die cavity in the form of circular ring, each monolithic module 20 and front end plate 18 and The rear splints 21 are fixedly connected by bolts. The single block module 20 is composed of two parallel baffle plates 2001, 2003 and a connecting plate 2002 between the two baffle plates 2001, 2003. The connecting plate 2002 is connected with the baffle plate 2001, A material forming groove is formed between 2003, and two adjacent forming grooves form a discharge channel 22; the outer side of the template assembly 11 is fixedly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com