Array substrate, liquid crystal panel and manufacturing methods of array substrate and liquid crystal panel

A liquid crystal panel and array substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven distribution of common electrodes, afterimages, etc., and achieve the effect of solving uneven distribution and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

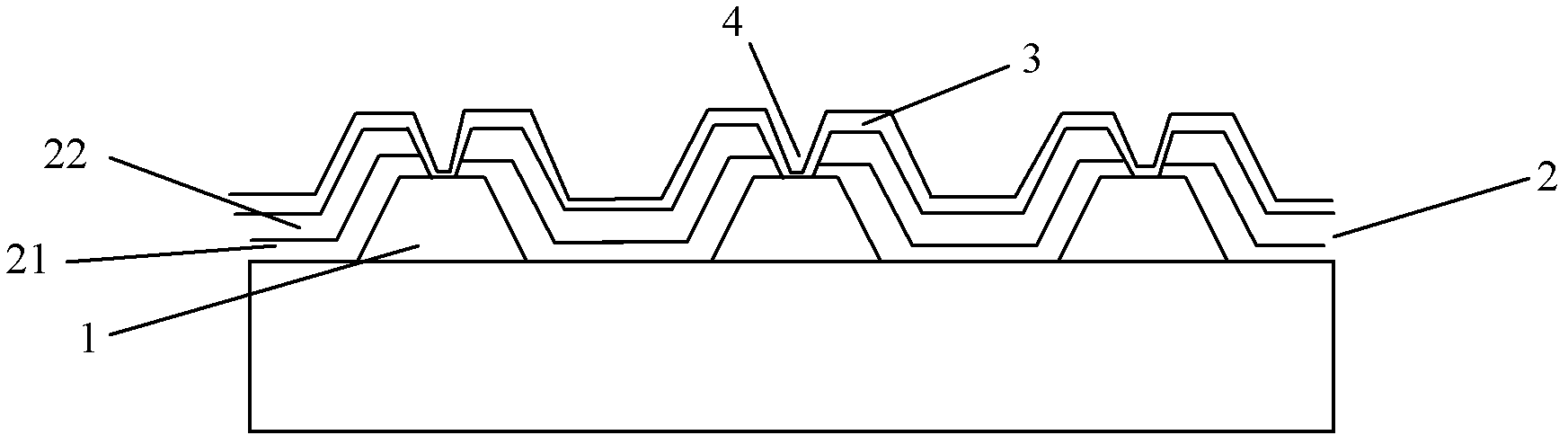

[0031] Such as figure 1 As shown, the embodiment of the present invention provides an array substrate, including a common electrode 1, a gate electrode (not shown in the figure), an insulating layer 2 and a transparent electrode layer 3; the insulating layer 2 covers the common electrode 1 and the gate electrode , and the insulating layer 2 has a via hole 4 at the position corresponding to the common electrode 1; the transparent electrode layer 3 covers the insulating layer 2, and the transparent electrode layer 3 forms an electrical connection with the common electrode 1 in the via hole 4. As a preferred solution, the transparent electrode layer 3 is formed by using indium tin oxide and using a masking process. The insulating layer 2 actually includes two layers of the gate insulating layer 21 and the insulating layer 22, but the present invention does not relate to the respective technical characteristics of the gate insulating layer 21 and the insulating layer 22, so the ga...

Embodiment 2

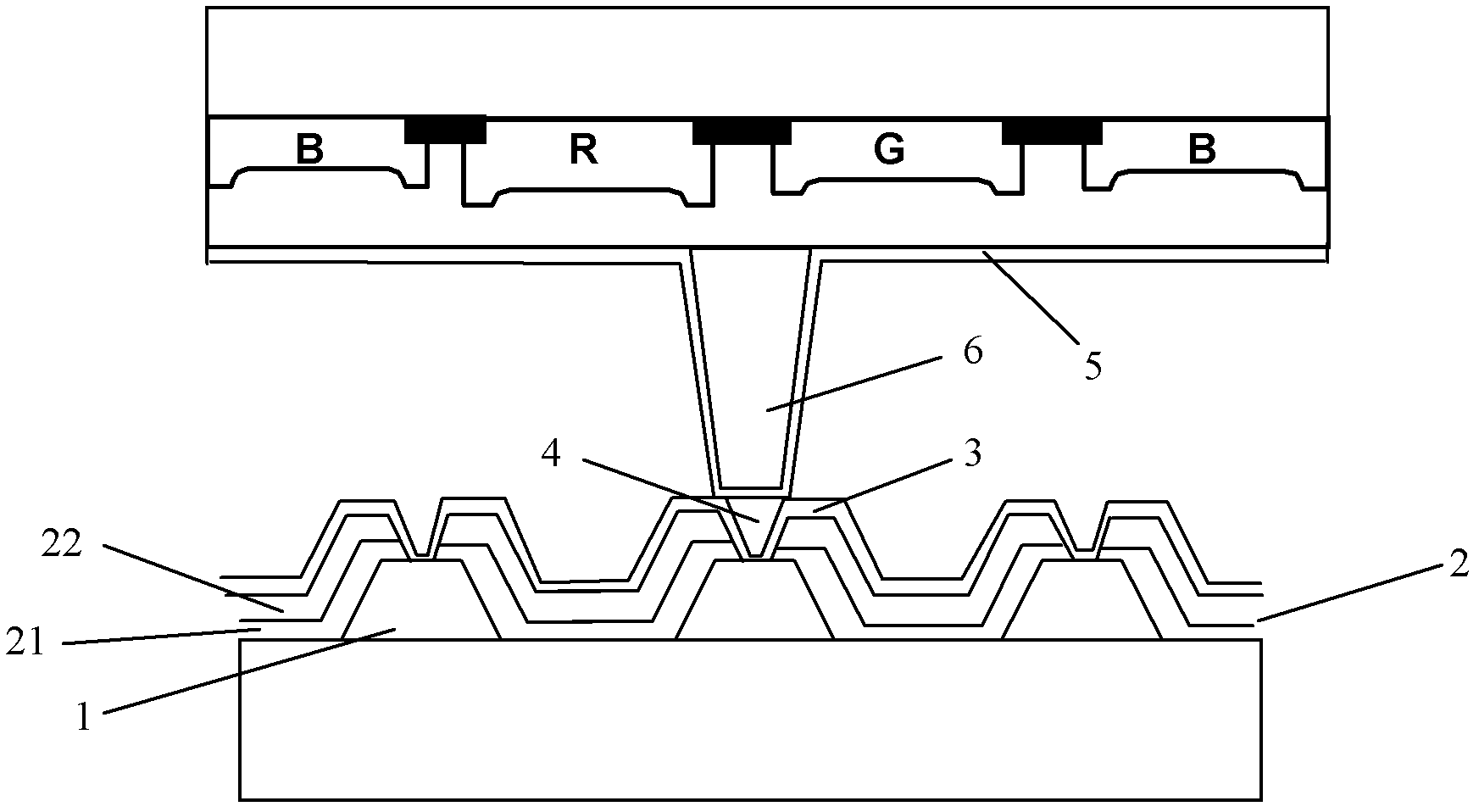

[0034] Such as figure 2 As shown, the embodiment of the present invention also provides a liquid crystal panel, including an array substrate and a color filter substrate; the array substrate includes a common electrode 1, a gate electrode, an insulating layer 2 and a transparent electrode layer 3; the insulating layer 2 covers the common electrode 1 and the gate electrode, and the insulating layer 2 has a via hole 4 at the position corresponding to the common electrode 1; the transparent electrode layer 3 covers the insulating layer 2, and the transparent electrode layer 3 forms an electrical connection with the common electrode 1 in the via hole 4 .

[0035] The transparent electrode layer of the array substrate is connected to the common electrode in the via hole, and a normal electrode is formed on the basis of the original planar electrode, thereby forming a common electrode with a three-dimensional structure. The distribution of voltage on the common electrode of the th...

Embodiment 3

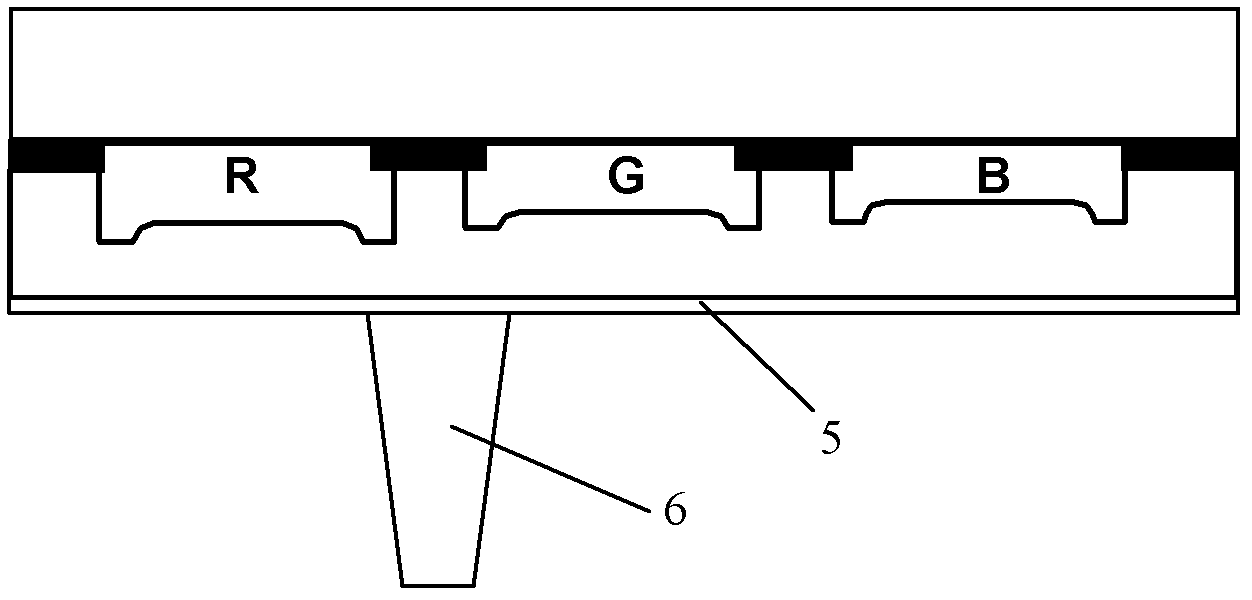

[0042] This embodiment is basically the same as Embodiment 2, the difference is: as Figure 4 As shown, in this embodiment, the color filter common electrode 5 covers the spacer 6 to form a conductive spacer. When the spacer 6 is first formed on the color filter substrate, and then the color filter common electrode layer 5 is formed, the color filter common electrode layer 5 will cover the spacer, so that the outer layer of the spacer is conductive, that is, conductive. spacer6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com