Gas-solid phase catalytic reactor

A catalytic reactor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

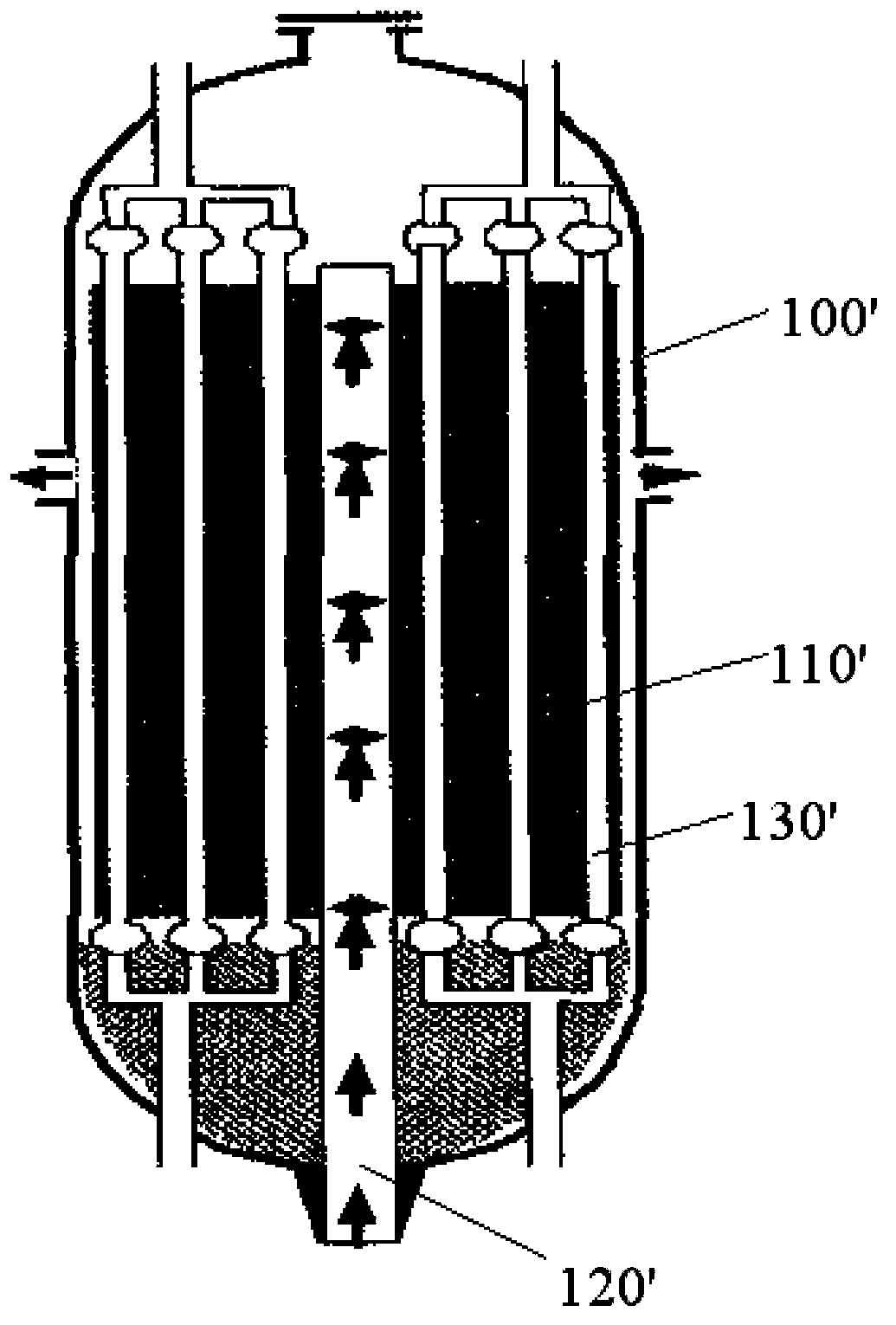

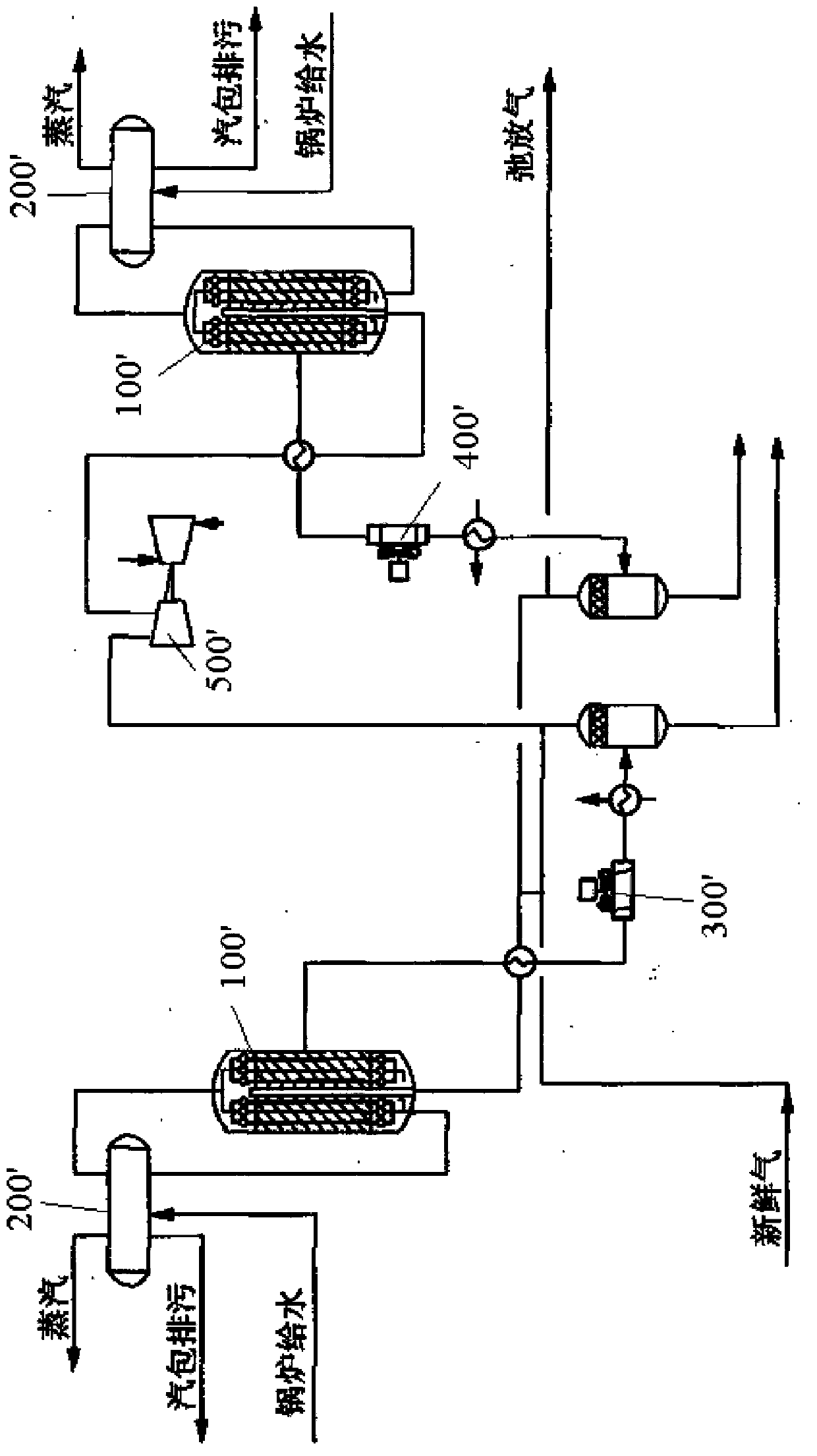

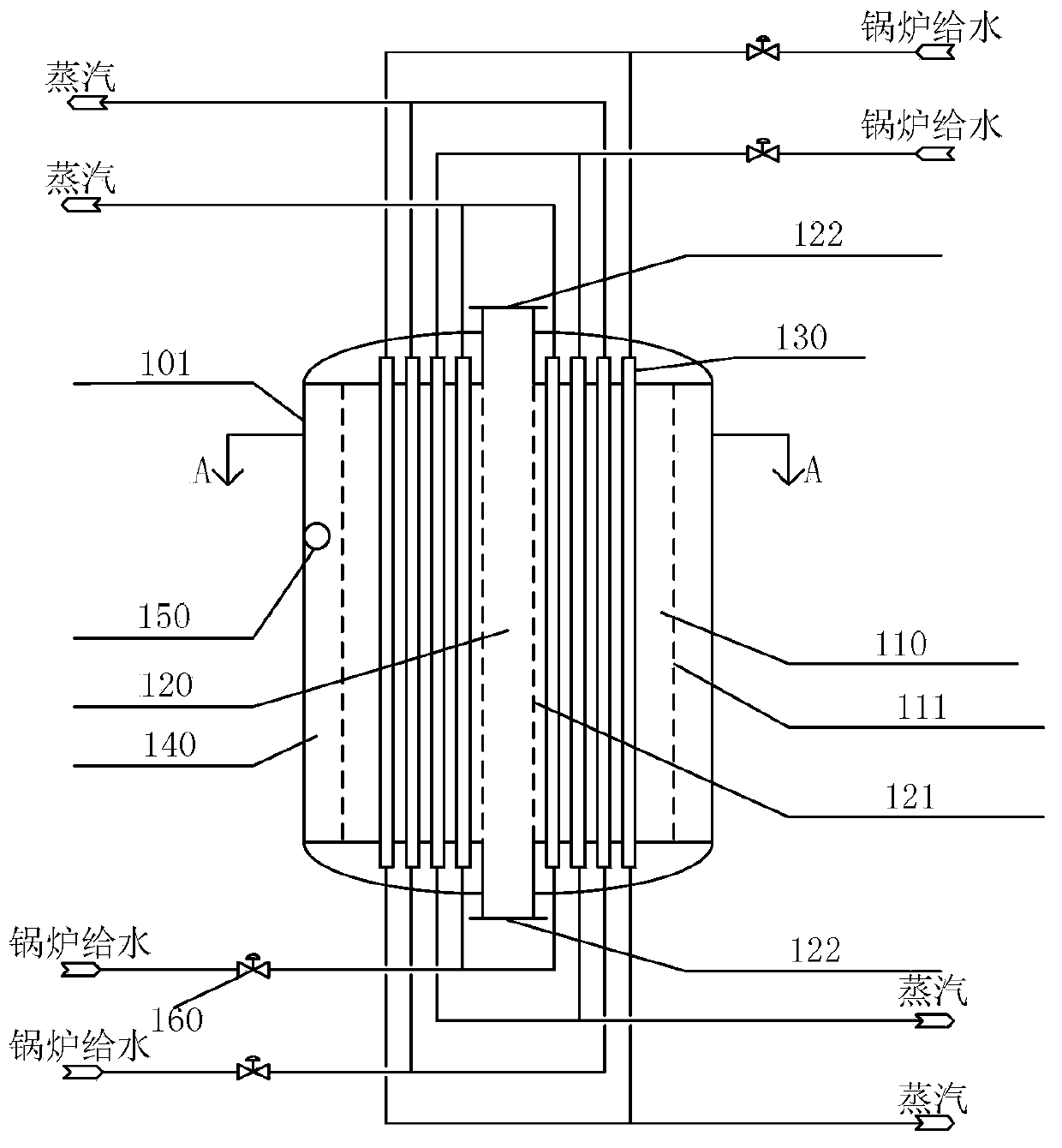

[0032] According to a typical embodiment of the present invention, such as image 3 As shown, the gas-solid phase catalytic reactor includes a reactor shell 101, a catalyst bed 110 and a heat exchange device, wherein a gas inlet pipeline 150 extending along the tangential direction of the side wall is formed on the side wall of the reactor shell 101; The catalyst bed 110 is arranged in the reactor shell 101, and an annular swirl chamber 140 is formed between the reactor shell 101. The catalyst bed 110 is a hollow cylinder, and the shell of the catalyst bed 110 is provided with a The catalyst bed 110 communicates with through holes 111 , and the heat exchange device is arranged in the catalyst be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com