Bipolar non-punch-hrough power semiconductor device

A semiconductor and power-through technology, which is applied in the field of bipolar non-through power semiconductor devices and manufactures such power semiconductor devices, can solve problems such as slowness and high loss, and achieve the goals of reducing thermal budget, short diffusion time, and saving thermal budget Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

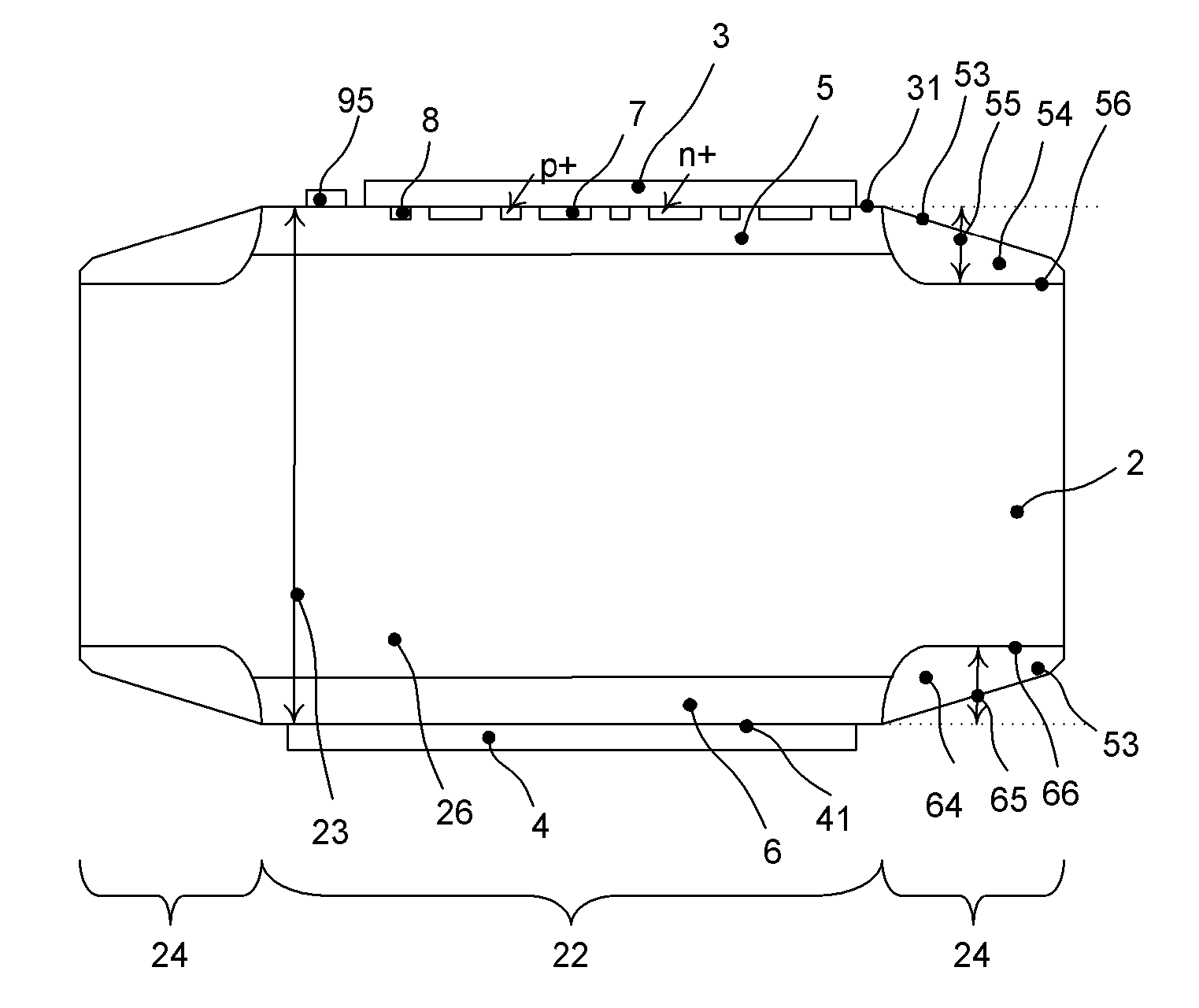

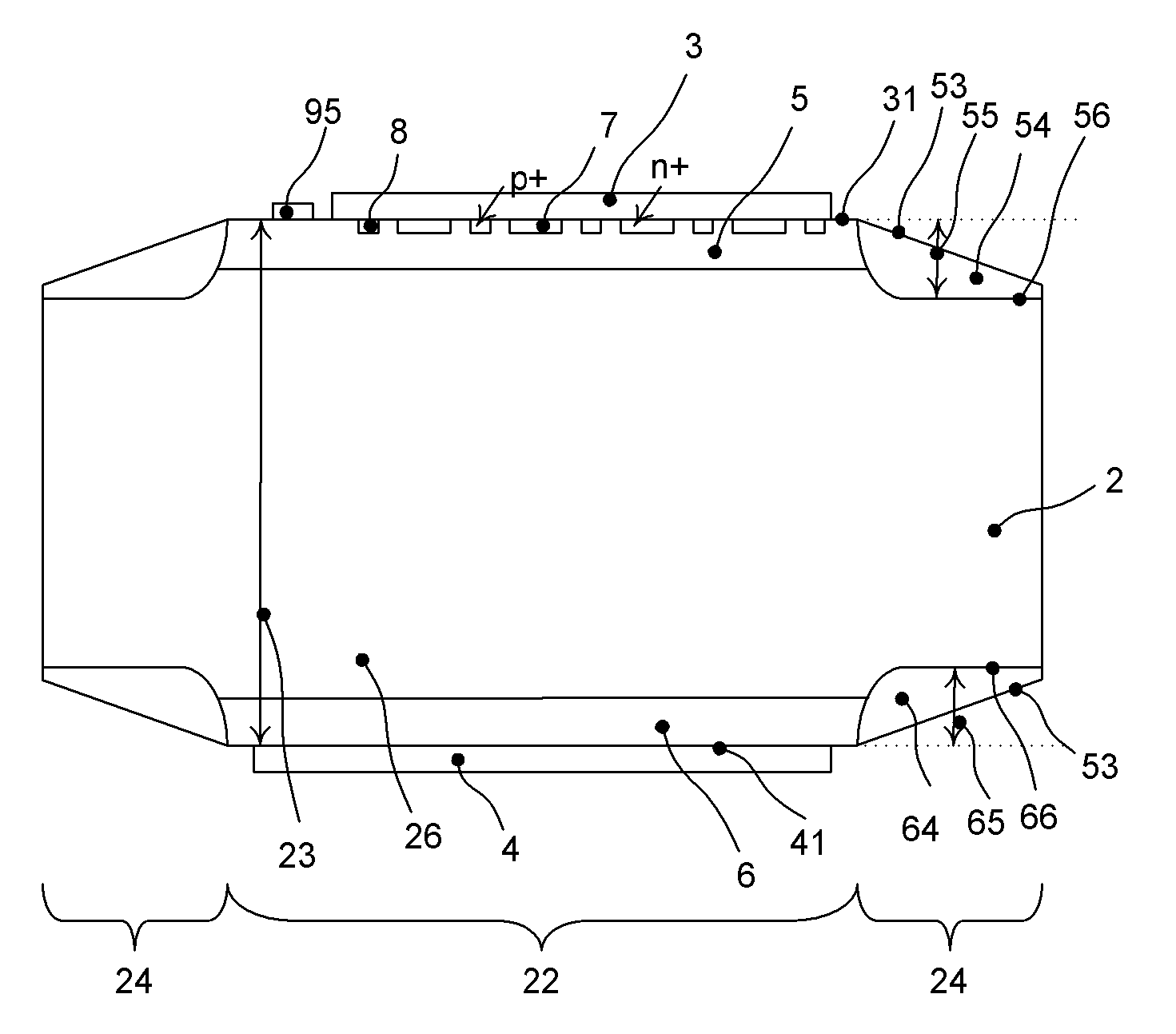

[0041] A bipolar non-punch-through power semiconductor arrangement according to the invention in the form of a phase-controlled thyristor (PCT) 1 with a blocking voltage of at least 1000 V is shown in FIG. 2 . The device comprises a semiconductor wafer 2 having layers of different conductivity types on which a cathode contact 3 is formed on a cathode side 31 of the wafer and an anode contact 4 is formed on an anode side 41 of the wafer opposite to the cathode side 31 . An (n-)doped drift layer 26 is formed in the wafer. A p-doped base layer 5 is arranged on this drift layer 26 towards the cathode side 31 . It touches the cathode contact 3. The base layer 5 is arranged directly adjacent to the drift layer 26 , which means that no further intermediate layers of the second conductivity type are arranged between the base layer 5 and the drift layer 26 . The base layer 5 and the drift layer 26 are connected to each other, ie they touch each other. The base layer 5 extends in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com