Ion implantation method of substrate back of power device

A technology of power devices and ion implantation, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems that power devices cannot be used, power device leakage current, on-state voltage drop switching time becomes larger, etc., to achieve Reduced on-state voltage drop, reduced switching time, and reduced contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

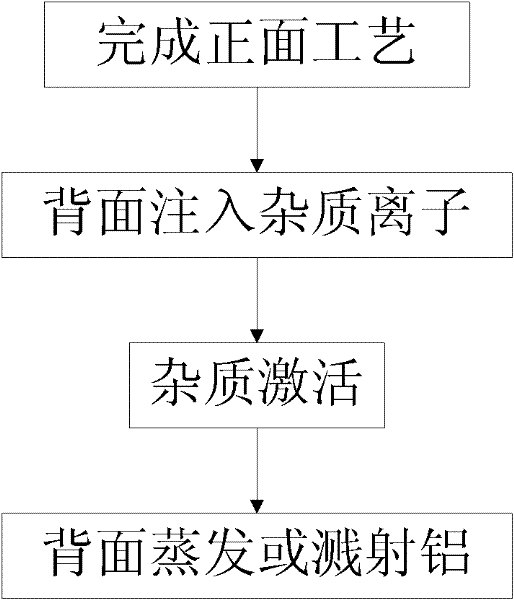

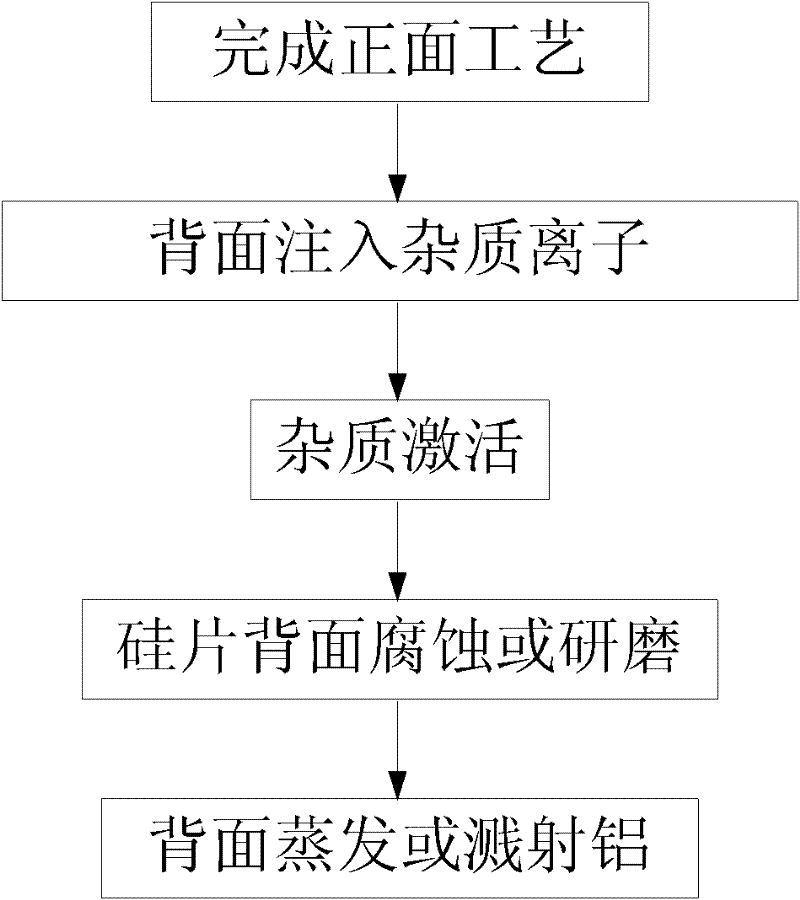

[0023] A method of ion implantation on the backside of a power device substrate, such as figure 2 As shown, after completing the front-side process steps of the power device, an operation including the following steps is performed:

[0024] Step 1: Implanting boron or phosphorus impurity ions on the back of the power device substrate;

[0025] Step 2: Activation of impurity ions;

[0026] Step 3: The back side of the power device substrate is thinned to the impurity injection layer;

[0027] Step 4: growing a metal aluminum layer on the back of the power device substrate by sputtering or evaporation.

[0028] In the above scheme, when implanting boron or phosphorus impurity ions on the back of the power device substrate in step 1, the implantation dose of the impurity ions is 1×10 13 ~2×10 15 cm -2 , the energy range is 30Kev~300Kev, and the injection depth is The present invention adopts a larger implantation energy than the usual ion implantation process, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com