Asymmetrical fast thyristor

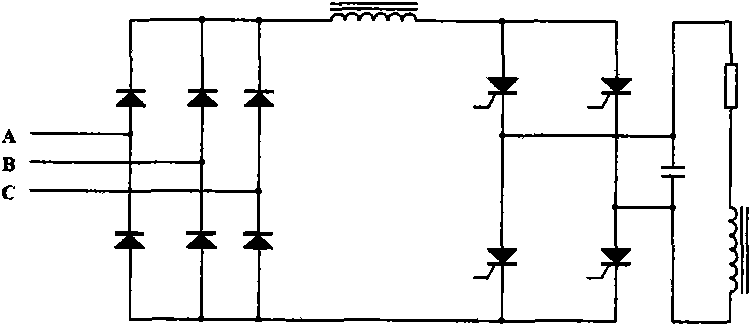

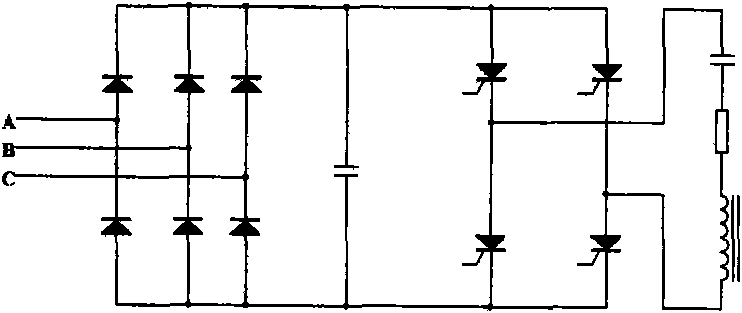

A thyristor, asymmetric technology, applied in the direction of thyristor, electrical components, circuits, etc., can solve the problems of overall device stability and reliability adverse effects, flow capacity limitation, poor dynamic characteristics, etc., to improve the on-state capacity and reduce Store charge, improve the effect of restoring softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

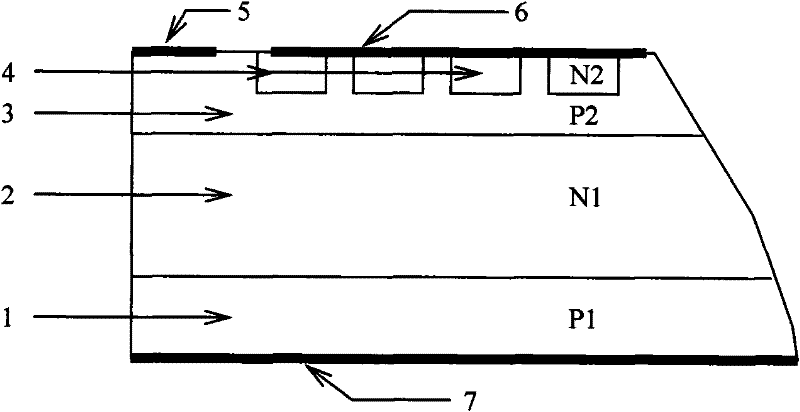

Embodiment 1

[0017] Example 1 as Figure 4 shown. The asymmetric thyristor includes a tube shell and a PNPN four-layer three-terminal semiconductor chip packaged in the tube shell. The junction depth of P1 anode area 1 is 15-80 μm; the junction depth of P2 area 3 at the cathode end is 45-130 μm, and the surface concentration is 1.5-8×10 17 cm -3 ; The thickness of the long base region 2 of N1 is 110-350 μm; the P in the anode region 1 of P1 + The surface concentration of the high concentration region 8 is 2×10 19 ~9.5×10 20 cm -3 . The junction depth of the P1 anode region 1 of the semiconductor chip is 20% to 70% of the junction depth of the P2 region 3 at the cathode end, and the thickness of the N1 long base region 2 is 20% to 30% thinner than that of a general thyristor. The P in the P1 anode region 1 + High concentration region 8 is formed by single window diffusion, P + The junction depth of the high concentration region 8 is smaller than the junction depth of the anode regio...

Embodiment 2

[0035] Example 2 as Figure 5 shown. The difference from Example 1 is that the P+ high-concentration region 9 in the P1 anode region 1 is formed by multi-window diffusion, and the P + The junction depth of the high concentration region 9 is smaller than the junction depth of the anode region 1 of P1.

Embodiment 3

[0036] Example 3 as Figure 6 shown. The difference from Example 1 is that the P+ high-concentration region 10 in the anode region of P1 is formed by multi-window diffusion, and the P + The junction depth of the high concentration region 10 is greater than the junction depth of the anode region of P1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com