Process for solving coal gas desulfuration liquid expansion in coking industry and system for process

A desulfurization liquid and gas technology, applied in the chemical industry, can solve the problems of desulfurization liquid expansion and difficult to solve, so as to avoid secondary pollution and solve the effect of uncontrollable water balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

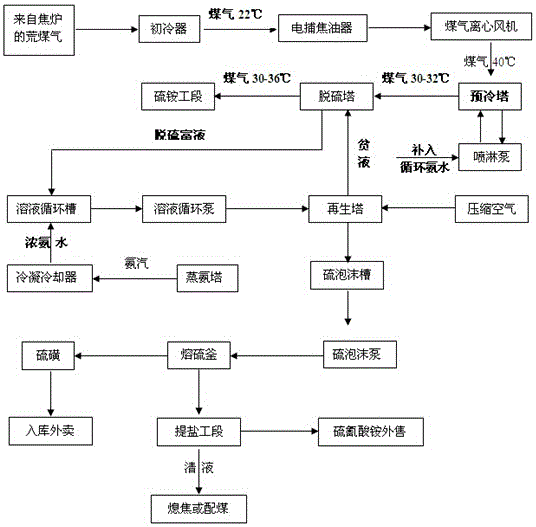

Method used

Image

Examples

Embodiment 1

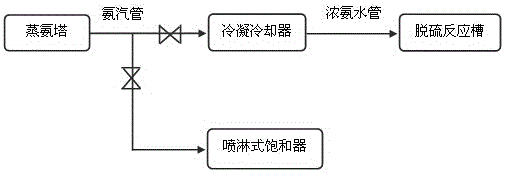

[0099] The technique for solving the expansion of gas desulfurization liquid in the coking industry of the present invention specifically includes the following steps:

[0100] (1) The gas (500-1200m 3 / h) Enter the ammonia blowing tower from bottom to top, and contact with the concentrated ammonia water entering from the top of the tower in reverse. source, this part of the gas is desulfurized and then ammonium desulfurized and circulated in this way;

[0101] (2) The concentrated ammonia water at about 45-55°C from ammonia distillation enters the ammonia blowing tower from top to bottom, and contacts with the gas entering from the bottom of the ammonia blowing tower in reverse, the ammonia in the concentrated ammonia water is taken away with the gas, and the remaining water is It is discharged from the bottom of the tower and pumped to the cold drum tar tanker. After sedimentation and separation, the upper ammonia water enters the circulating ammonia water system, and then ...

Embodiment 2

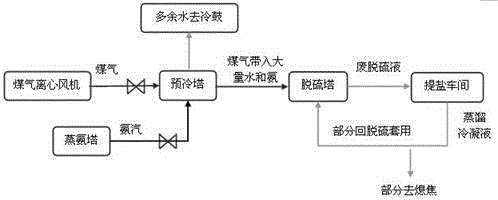

[0132] The technique for solving the expansion of gas desulfurization liquid in the coking industry of the present invention specifically includes the following steps:

[0133] (1) Gas (500-1200m 3 / h) The gas is sent to the pre-cooling tower for pre-cooling through the gas centrifugal fan, and the pre-cooled gas enters the desulfurization tower for desulfurization. The desulfurized gas passes through ammonium sulfate to remove crude benzene, and then enters the ammonia blowing tower;

[0134] (2) After the concentrated ammonia water is discharged from the ammonia distillation tower, it enters the ammonia blowing tower, contacts and fully mixes with the gas entering the ammonia blowing tower, the ammonia in the concentrated ammonia water is taken away by the gas, and the remaining water is discharged from the bottom of the ammonia blowing tower Discharge, coal gas and ammonia are transported to the desulfurization tower as the alkali source of desulfurization through the gas b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com