New method for repairing waste tyre

A technology of waste tires and a new method is applied in the field of repairing waste tires, which can solve the problems of insufficient repair rate, unrepairable utilization, black pollution, etc., and achieve the effects of reducing costs, good resources, and improving the utilization rate of repairs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

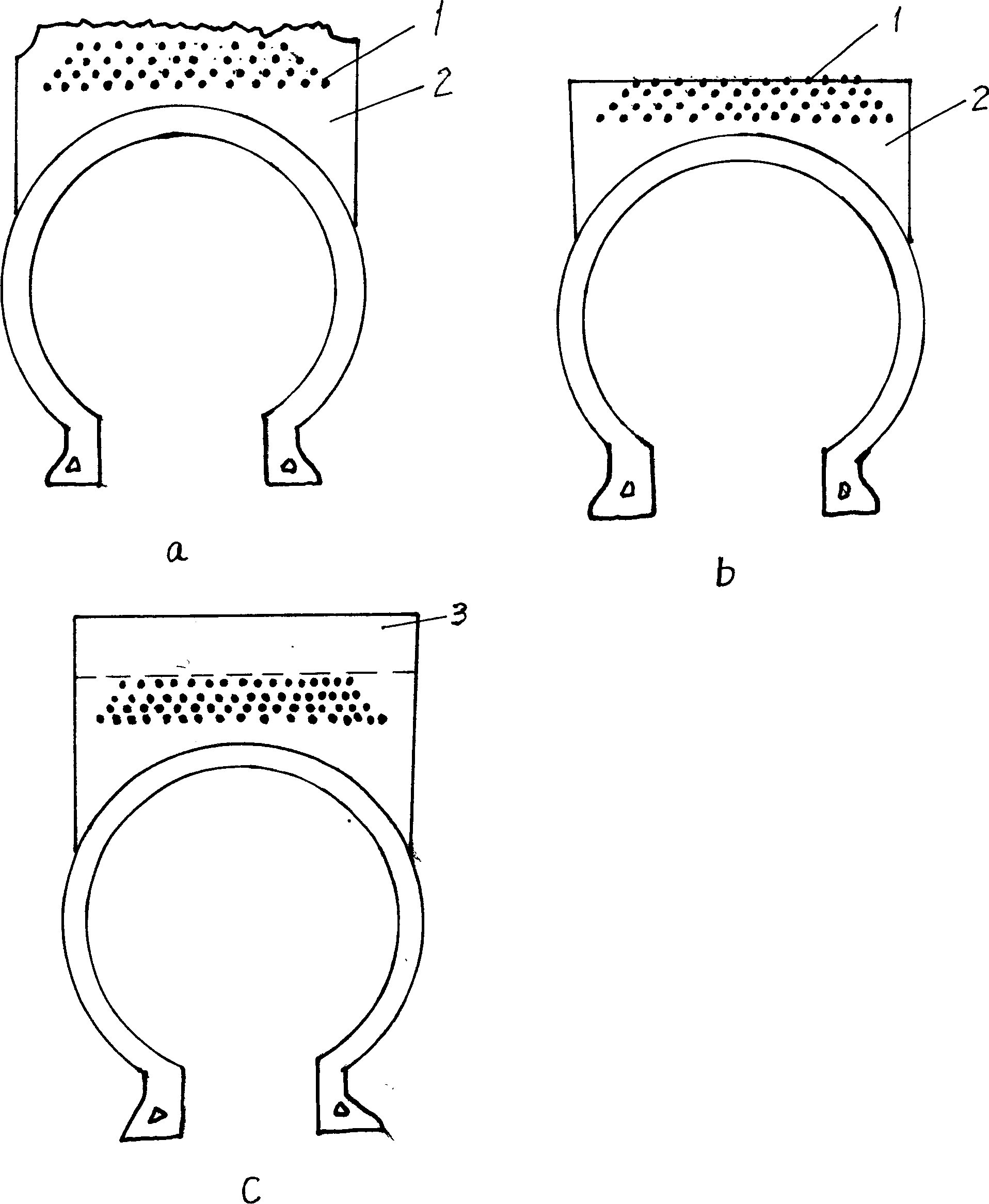

[0049] 1. Carry out carcass selection first, and waste carcasses can be divided into four grades: A, B, C and D.

[0050] 1. The tread surface is normally worn to no pattern is a grade A carcass.

[0051] 2. If the tread surface pattern is worn normally and the tread wire is damaged for 1-3 layers, it is a Class B carcass.

[0052] 3. Regardless of the depth of the pattern wear, the carcass that is obliquely blasted at the top of the tire and cracks appear in the transverse skeleton of the steel wire is a Class C carcass (referred to as a single seam carcass).

[0053] 4. Regardless of the depth of pattern wear, the tire with horizontal steel wire blasting is called D-grade carcass.

[0054] 2. Repair

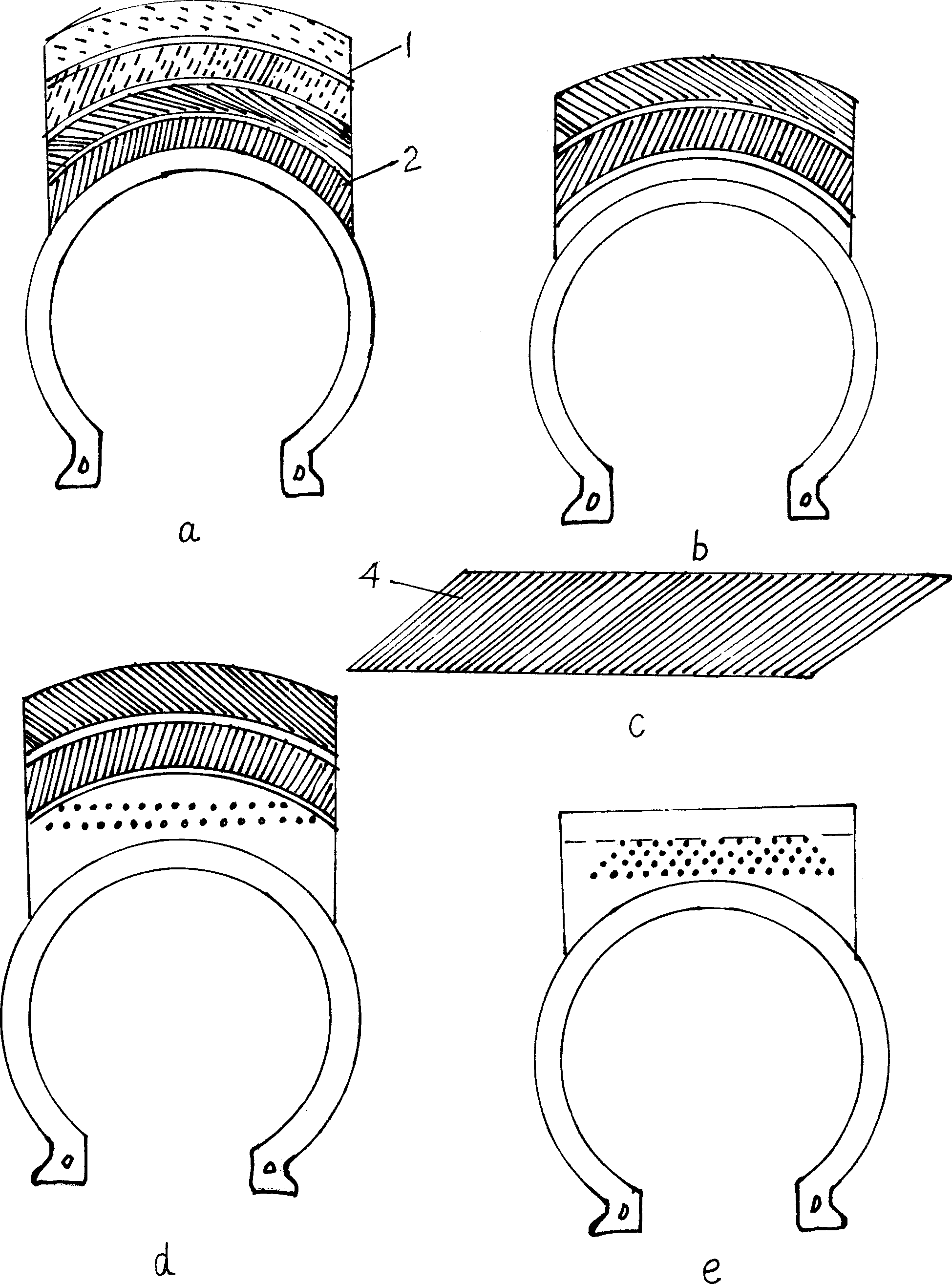

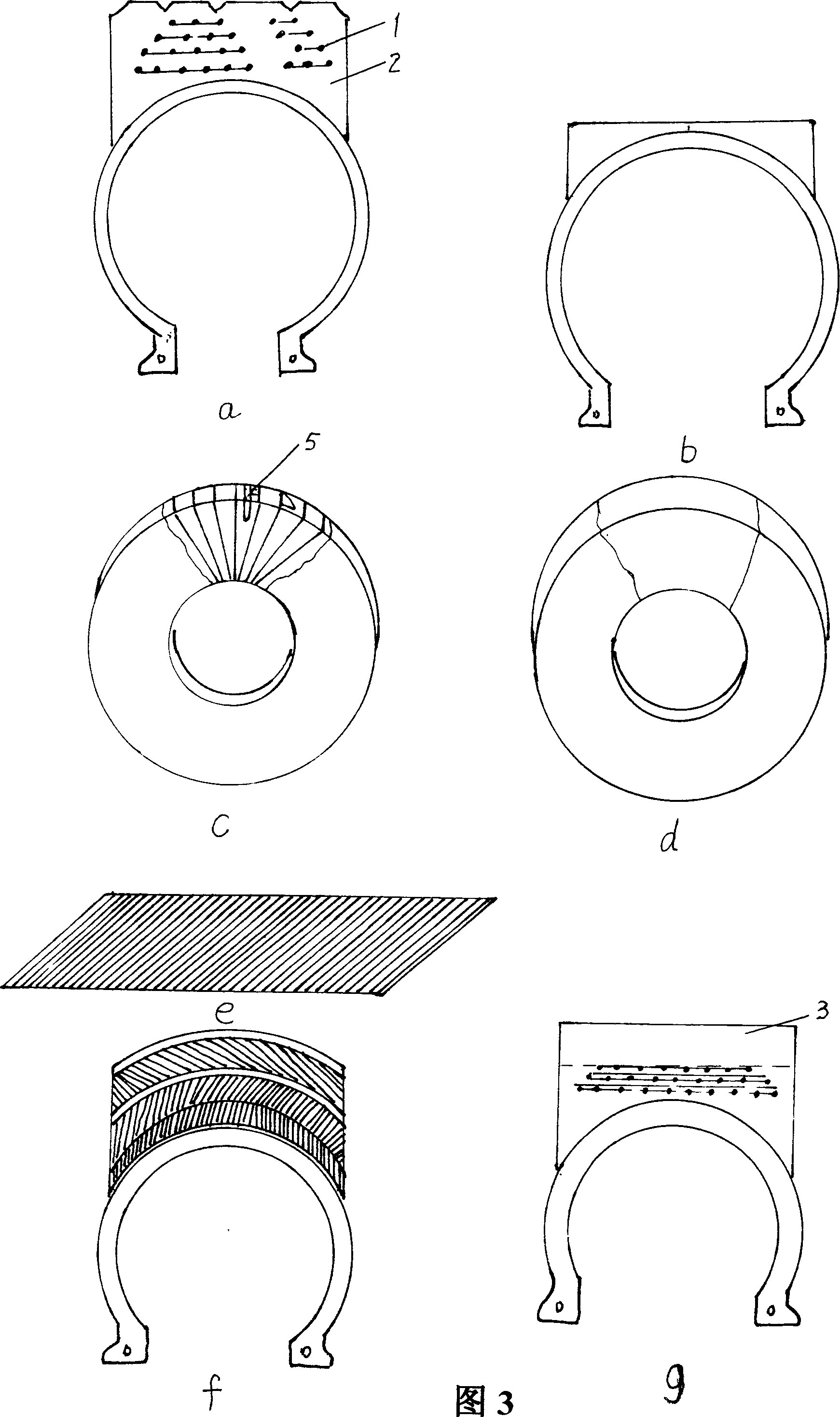

[0055] 1. The repair process of Grade A carcass: see figure 1 a, b, first, the carcass is imitated and polished, and the old skin on the surface is carefully treated until the new oblique steel wire mesh surface 1 is exposed.

[0056] Then place the carcass 2 in the drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com