Benzyl benzoate waste mixed modified asphalt and preparation method thereof

A technology of benzyl benzoate and modified asphalt, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of unavailable treatment methods, environmental pollution, etc., and achieve environmental protection, reduce costs, and solve coal tar pitch excess effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

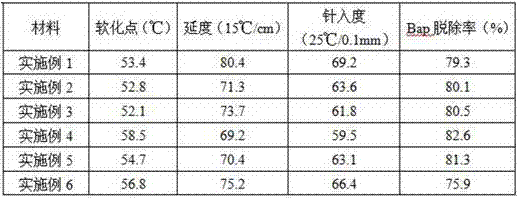

Examples

Embodiment 1

[0025] A benzyl benzoate waste mixed modified asphalt, characterized in that: the modified asphalt is made of the following raw materials in parts by weight: 60 parts of 10# petroleum asphalt, 30 parts of low-temperature coal tar pitch, 40 parts of benzyl benzoate waste , 30 parts of ethylene glycol monomethyl ether, 10 parts of ethylene glycol, 3 parts of alkylphenol polyoxyethylene ether, 3 parts of aluminum isopropoxide, and 3 parts of zinc stannate.

[0026] The preparation method of benzyl benzoate scrap mixed modified asphalt comprises the following processing steps:

[0027] (1) First put the two kinds of asphalt into the reaction kettle with reflux device, heat it to 60-110°C, then add ethylene glycol monomethyl ether and ethylene glycol into the kettle, stir for 20-30min, and the stirring speed is 300- 500r / min;

[0028] (2) Then add benzyl benzoate waste, alkylphenol polyoxyethylene ether, aluminum isopropoxide and zinc stannate to the reaction kettle in sequence, s...

Embodiment 2

[0031] A kind of benzyl benzoate leftover mixed modified asphalt is characterized in that: the modified asphalt is made of the following raw materials in parts by weight: 60 parts of 10# petroleum asphalt, 15 parts of low temperature coal tar pitch, 15 parts of medium temperature coal tar pitch, benzene 50 parts of benzyl formate scrap, 30 parts of ethylene glycol monomethyl ether, 12 parts of ethylene glycol, 5 parts of alkylphenol polyoxyethylene ether, 2 parts of aluminum isopropoxide, and 3 parts of zinc stannate.

[0032] The preparation method of benzyl benzoate scrap mixed modified asphalt comprises the following processing steps:

[0033] (1) First put the two kinds of asphalt into the reaction kettle with reflux device, heat it to 60-110°C, then add ethylene glycol monomethyl ether and ethylene glycol into the kettle, stir for 20-30min, and the stirring speed is 300- 500r / min;

[0034] (2) Then add benzyl benzoate waste, alkylphenol polyoxyethylene ether, aluminum is...

Embodiment 3

[0037] A benzyl benzoate waste mixed modified asphalt, characterized in that: the modified asphalt is made of the following raw materials in parts by weight: 60 parts of 10# petroleum asphalt, 30 parts of medium temperature coal tar pitch, 60 parts of benzyl benzoate waste , 25 parts of ethylene glycol monomethyl ether, 15 parts of ethylene glycol, 5 parts of alkylphenol polyoxyethylene ether, parts of isopropanol,

[0038] The preparation method of benzyl benzoate scrap mixed modified asphalt comprises the following processing steps:

[0039] (1) First put the two kinds of asphalt into the reaction kettle with reflux device, heat it to 60-110°C, then add ethylene glycol monomethyl ether and ethylene glycol into the kettle, stir for 20-30min, and the stirring speed is 300- 500r / min;

[0040] (2) Then add benzyl benzoate waste, alkylphenol polyoxyethylene ether, aluminum isopropoxide and zinc stannate to the reaction kettle in sequence, stir for 1-2 hours, and the stirring spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com