Method for producing milk wine

A technology of milk wine and fresh milk, which is applied in the field of wine making, can solve the problems of increasing the pressure on milk suppliers, prolonging the production cycle of milk wine, and the growth of lactic acid bacteria, and achieve the effects of shortening the fermentation time, no suspended matter, and stable properties of milk wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

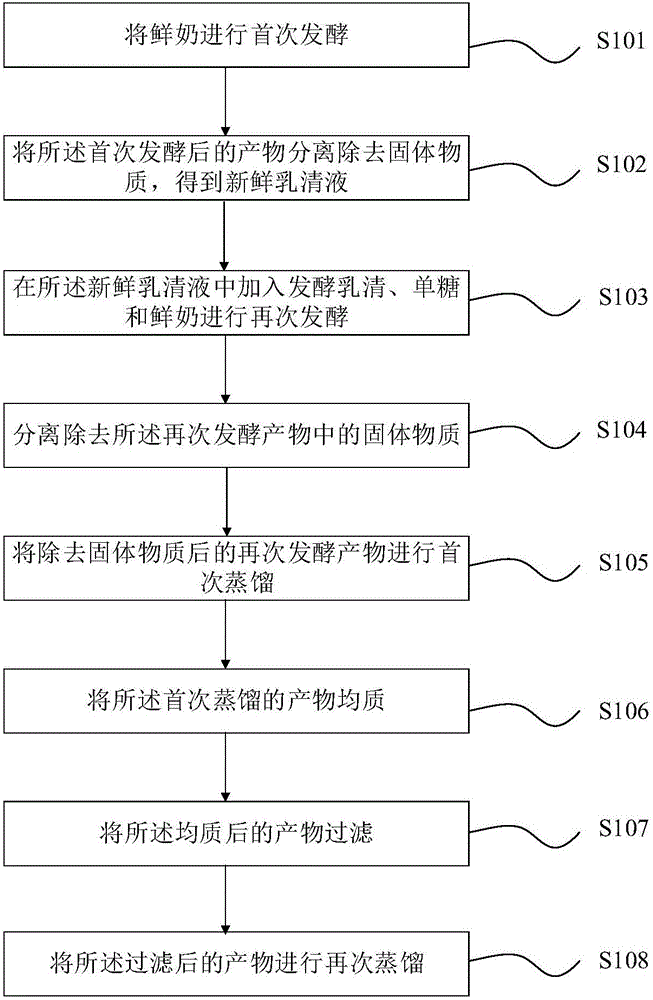

Method used

Image

Examples

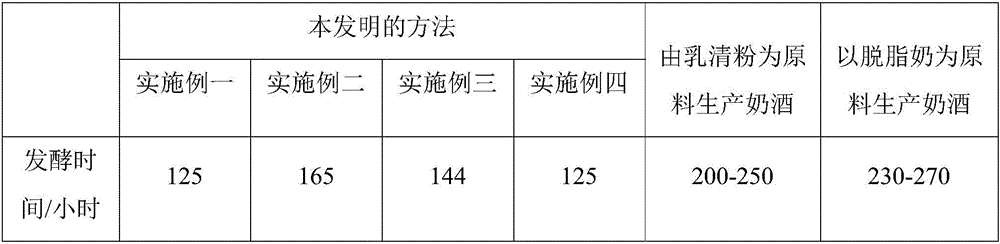

Embodiment 1

[0029] Ferment fresh milk at 20°C for 40 hours, separate and remove fat and other solid substances to obtain fresh whey liquid; the weight ratio of fresh whey liquid and fermented whey is 4:1, and the weight ratio of fresh whey liquid and simple sugar is The ratio is 10:1, fresh whey liquid and fresh milk are mixed at a weight ratio of 3:1, and then the mixed solution is fermented at 20°C for 85 hours to obtain a re-fermented product; the re-fermented product is separated and removed After solid matter, distill it for the first time at 90°C for 1 hour to obtain milk wine with an alcohol content of 11%; homogenize and filter the product after the first distillation, and distill the filtered product at 90°C for 2 hours to obtain the alcohol content It is 30% milk wine.

Embodiment 2

[0031] Ferment fresh milk at 25°C for 60 hours, separate and remove fat and other solid substances to obtain fresh whey liquid; the weight ratio of fresh whey liquid and fermented whey is 10:1, and the weight ratio of fresh whey liquid and simple sugar is The ratio is 30:1, fresh whey liquid and fresh milk are mixed at a weight ratio of 10:1, and then the mixed solution is fermented at 25°C for 105 hours to obtain a re-fermented product; the re-fermented product is separated and removed After the solid matter, distill it for the first time at 100°C for 3 hours to obtain milk wine with an alcohol content of 28%; homogenize and filter the product after the first distillation, and distill the filtered product at 100°C for 1 hour to obtain the alcohol content It is 70% milk wine.

Embodiment 3

[0033] Ferment fresh milk at 23°C for 48 hours, separate and remove fat and other solid substances to obtain fresh whey liquid; the weight ratio of fresh whey liquid and fermented whey is 6:1, and the weight ratio of fresh whey liquid and simple sugar is The ratio is 20:1, fresh whey liquid and fresh milk are mixed at a weight ratio of 8:1, and then the mixed solution is fermented at 23°C for 96 hours to obtain a re-fermented product; the re-fermented product is separated and removed After solid matter, distill it for the first time at 95°C for 2 hours to obtain milk wine with an alcohol content of 20%; homogenize and filter the product after the first distillation, and distill the filtered product at 95°C for 3 hours to obtain the alcohol content It is 50% milk wine.

[0034]Certainly, except the situation enumerated in embodiment one to embodiment three, other ratios of each material in other fermentation temperature, fermentation time, distillation temperature, distillation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com