Method for producing cathode nickel by selective leaching-electrodeposition of high nickel matte

A cathode nickel, selective technology, applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of acid imbalance in the production system, increased waste water discharge, unfavorable environmental protection, etc., to solve the problem of excess acid in the production system, promote Leaching, the effect that is beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

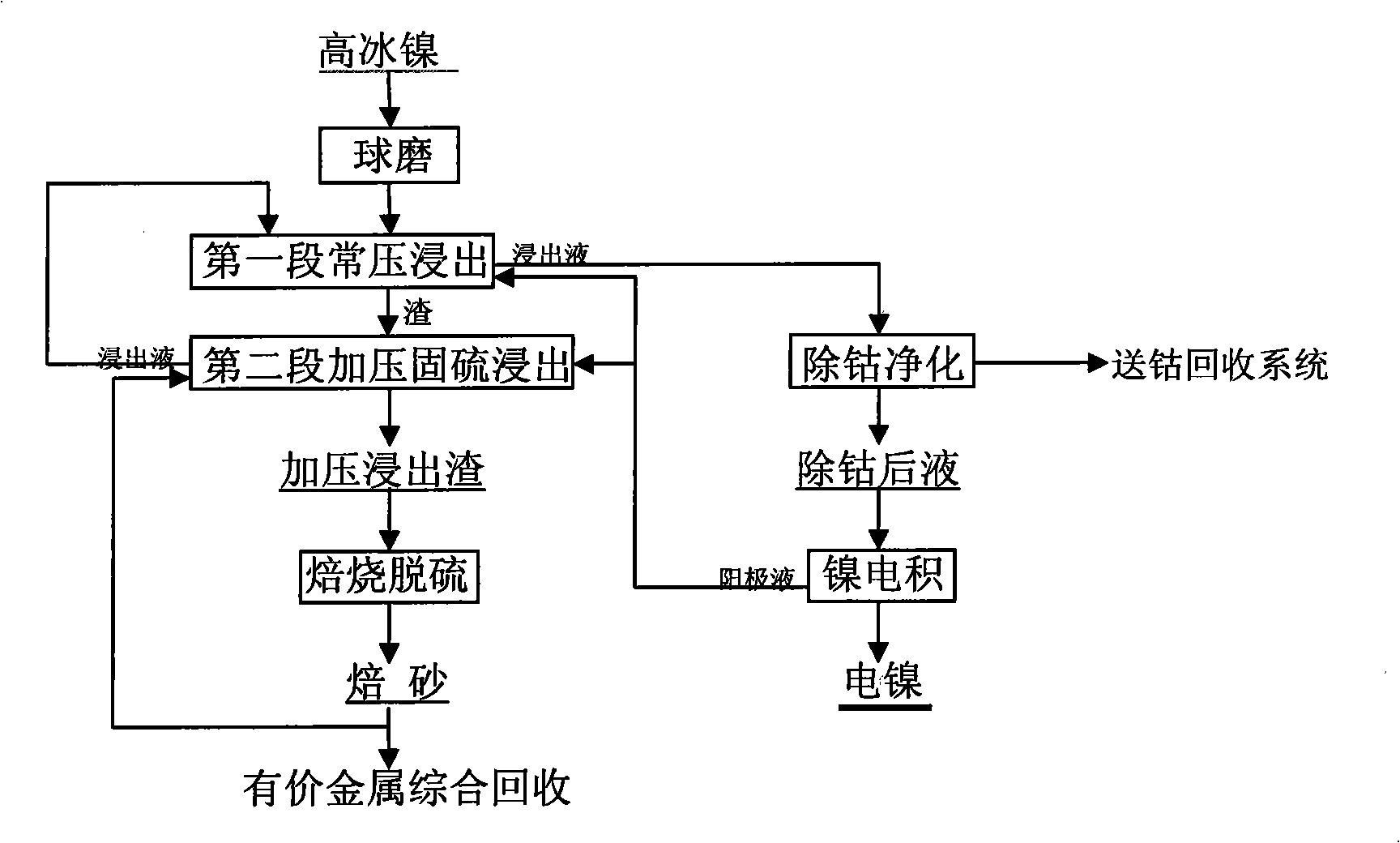

Method used

Image

Examples

Embodiment 1

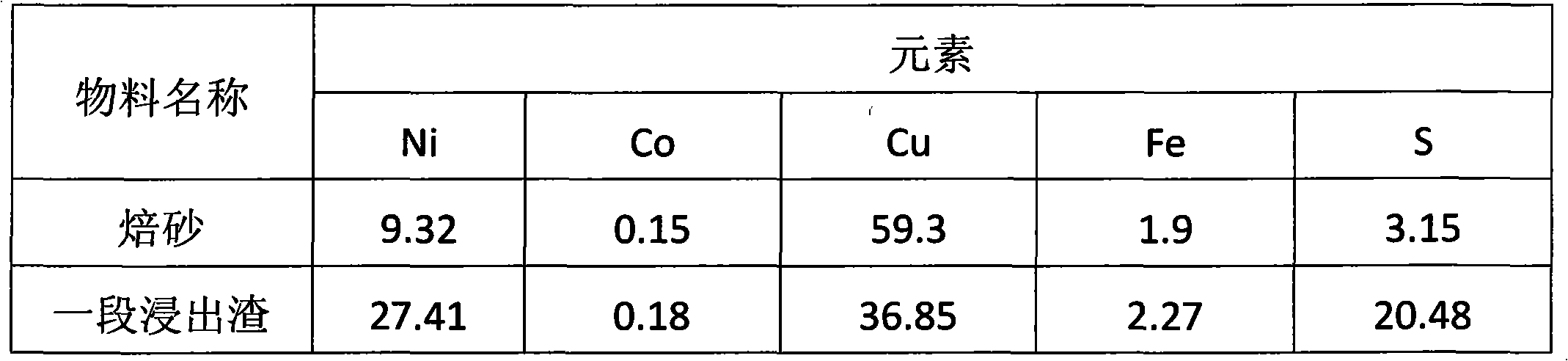

[0025] In the second-stage pressure-fixed sulfur leaching, the anolyte is used as the leaching agent, and the calcine of the second-stage pressure leaching slag is used as the sulfur-fixing agent. The composition of primary atmospheric pressure leaching slag, calcined sand and anolyte is listed in the following table.

[0026] Table 1 1st stage normal pressure leaching slag and calcined sand composition (%)

[0027]

[0028] Table 2 Anolyte composition (g / L)

[0029] Element

Ni

h 2 SO 4

Content (g / L)

60.44

51.9

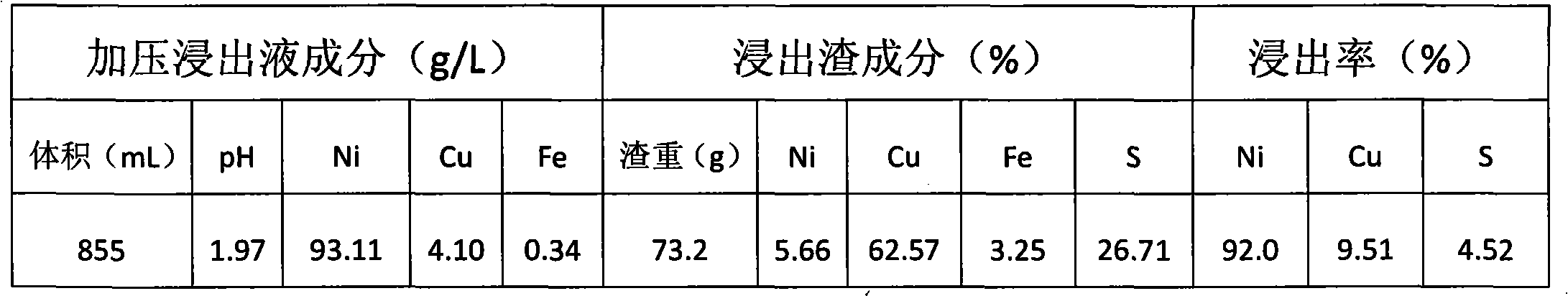

[0030] Add 100g of atmospheric pressure leaching residue, 21g of calcine and 900mL of anolyte into a 2L electromagnetically stirred autoclave, heat to 150°C, fill in air to control the oxygen partial pressure in the autoclave within the range of 0.02-0.06MPa, and pressurize the leaching 30min., cooling, and filtering to obtain 855mL of pressurized leaching solution and 73.2g of pressurized leaching residue. The results...

Embodiment 2

[0038] Put 100g of atmospheric pressure leaching residue, 25g of calcine and 900mL of anolyte into a 2L electromagnetically stirred autoclave, heat to 160°C, fill in air to control the oxygen partial pressure in the autoclave within the range of 0.02-0.06MPa, and pressurize for 30min ., cooled and filtered to obtain 850mL of pressurized leaching solution and 74.6g of pressurized leaching residue. The pressurized leaching results are listed in Table 5.

[0039] Table 5 Results of pressure-fixed sulfur leaching experiments

[0040]

Embodiment 3

[0042] Add 100g of atmospheric pressure leaching residue, 10g of calcine and 900mL of anolyte into a 2L electromagnetically stirred autoclave, heat to 180°C, fill in air to control the oxygen partial pressure in the autoclave within the range of 0.02-0.06MPa, and pressurize the leaching 30min., cooled, and filtered to obtain 840mL of pressurized leaching solution and 70.4g of pressurized leaching residue. The pressurized leaching results are listed in Table 6.

[0043] Table 6 Results of pressure-fixed sulfur leaching experiments

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com