Method for removing carbon deposition on turbine blade of aircraft engine through magnetic needle grinding

An aircraft engine, turbine blade technology, applied in machine tools, grinders, grinding/polishing equipment suitable for grinding workpiece edges, etc., can solve problems such as poor applicability, residual impurities, etc., achieve low material surface roughness, avoid environmental Contamination problems, the effect of achieving a high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

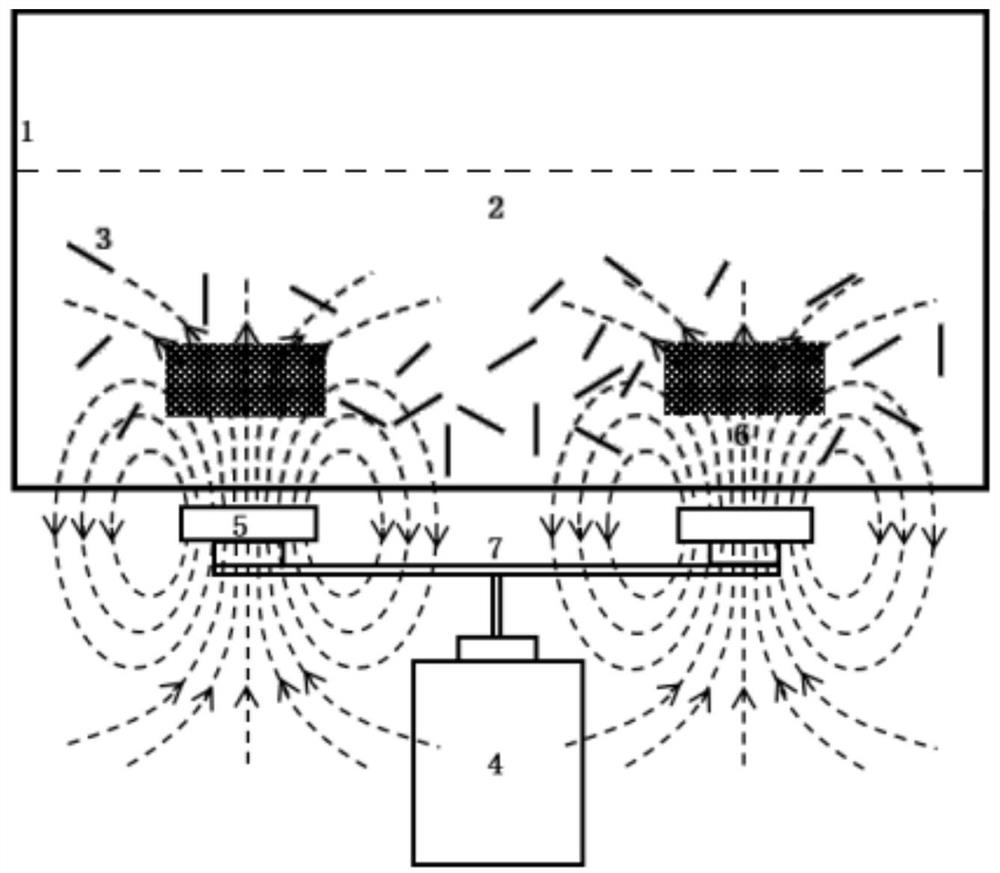

[0032] A device for grinding and removing carbon deposits on turbine blades with magnetic needles, which includes a cleaning tank 1 for placing cleaning liquid 2 and magnetic needles 3, a cooling circulation system for adjusting the temperature of the cleaning liquid, two permanent magnets 5 for driving magnetic needles 3, two The block permanent magnet 5 is connected with the output end of the motor 4 through a support beam 7 . The specifications of the magnetic needle 3 are: diameter 0.2-1.5mm, length 8-20mm, material is ferromagnetic material containing stainless steel, alloy containing any several elements of iron, cobalt and nickel. This implementation case is mainly aimed at the turbine guide vane of an aircraft engine. The diameter of the air hole is about 1 mm, and the inside of the air hole has a radian. According to the shape of the air hole, it is ensured that the magnetic needle does not enter the interior of the turbine blade. Therefore, the material of the magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com