Gas drainage method and equipment with alternative drainage

A technology of gas drainage and extraction, which is applied in the field of total gas drainage, can solve the problems of not being able to increase the amount of gas drainage, not being able to accelerate the desorption of gas, and reducing air permeability, etc., achieving wide practicability, low cost, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

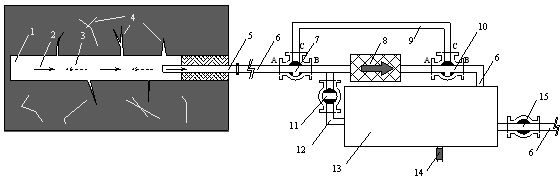

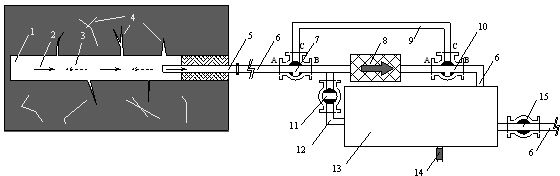

[0020] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

[0021] The gas drainage method with alternate suction and pressure of the present invention, because after the construction of the gas drainage borehole 1 is completed, the coal in a certain range around it is deformed due to pressure relief, and a large number of cracks 4 are generated at the same time, which is the desorption and flow of gas Provide conditions. First, pass the front and rear three-way ball valves 10, 7 in parallel with the bypass pipeline 9 on the main drainage pipeline 6 before and after the gas pump 8 in the underground coal mine, and connect the high-pressure storage pipeline to the drainage main pipeline 6 in front of the front three-way ball valve 10. Gas tank 13, the front part of the high-pressure gas storage tank 13 is connected to the outlet control ball valve 15, the rear part of the high-pressure gas storage tank 13 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com