A drilling method of upward pressure and downward drainage for steeply inclined coal seam penetration and drainage

A technology of piercing drilling and steep inclination, applied in the direction of earthwork drilling, mining fluid, mining equipment, etc., can solve the problems of aggravating the risk of coal and gas outburst, increasing the gas pressure of extended horizontal coal seams, and no fracturing , to achieve the effects of increasing the air permeability of the coal seam, increasing the radius of gas drainage, and being easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described further below:

[0025] A steeply inclined coal seam piercing drilling method for upward pressure and downward drainage, permeability enhancement and extraction, comprising the following steps:

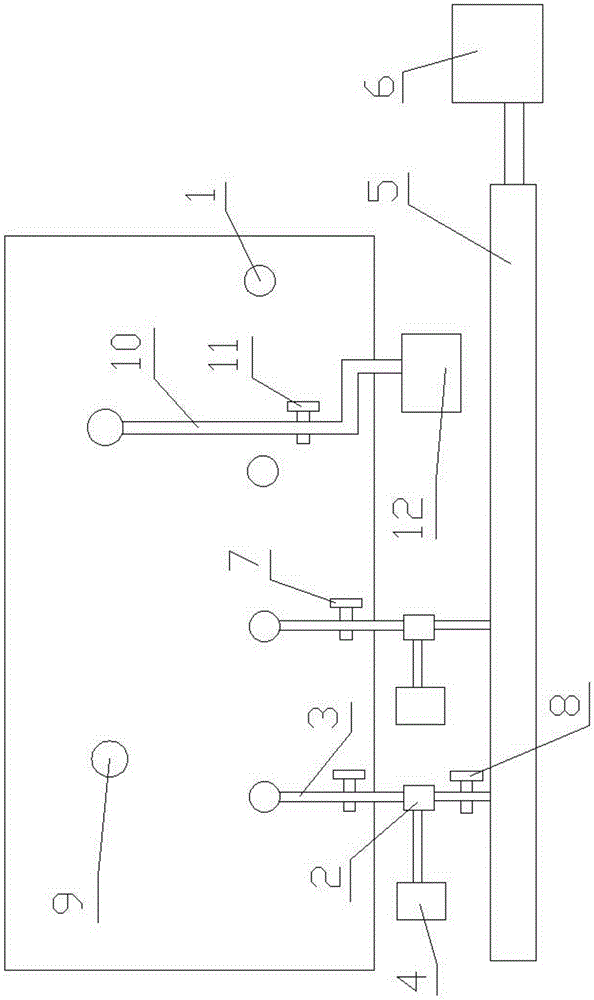

[0026] (1) In the floor roadway or the roadway adjacent to the mining coal seam, construct a number of cross-layer drainage drilling holes 1 to the coal seam to be enhanced in permeability, and carry out sealing operation on the rock hole part of each cross-layer drainage drilling hole 1, and use three The through pipe 2 connects the extraction pipe 3 drawn out of the drilling hole through the layer drainage with the drainer 4 and the extraction main pipe 5 respectively, and the extraction main pipe 5 is connected with the extraction pump 6, and the extraction pipe 3 is provided with Drainage pipeline valve 7, the connecting pipeline between the tee pipe 2 and the extraction main pipe 5 is provided with a drainage main pipe valve 8; 1 hole for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com