Testing device and measuring and calculating method for gas permeability of compact rock material

A technology for dense rock and material gas, applied in the direction of measuring devices, permeability/surface area analysis, and analyzing materials, can solve the problems of low liquid flow rate, large measurement error, and difficult test, etc., and achieve a wide range of confining pressure , simple operation and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

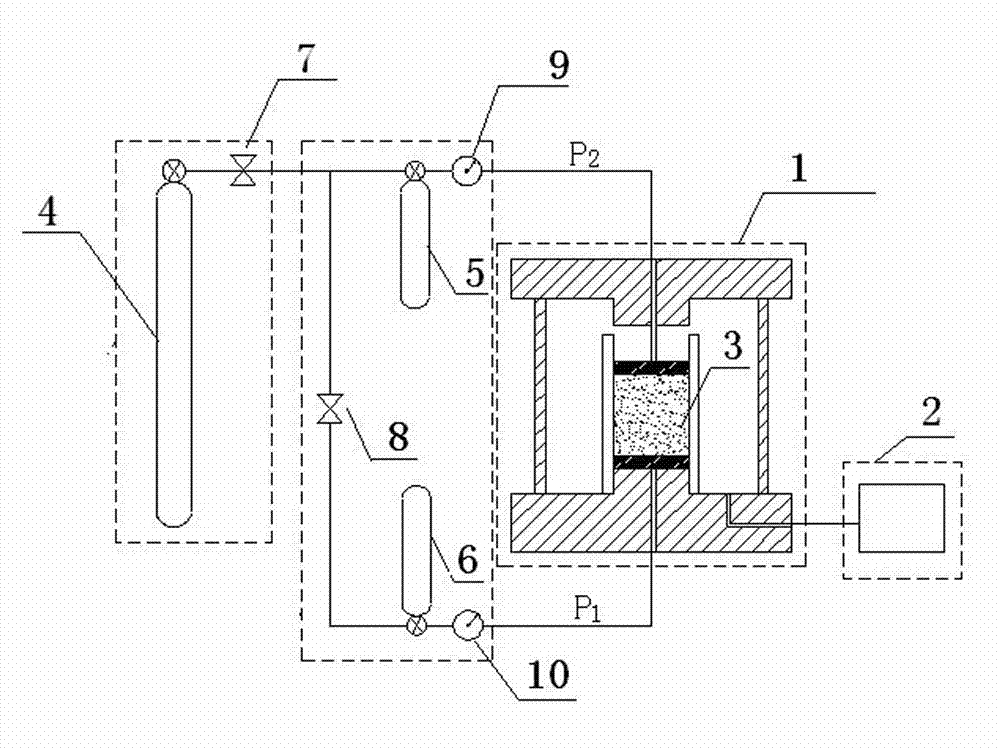

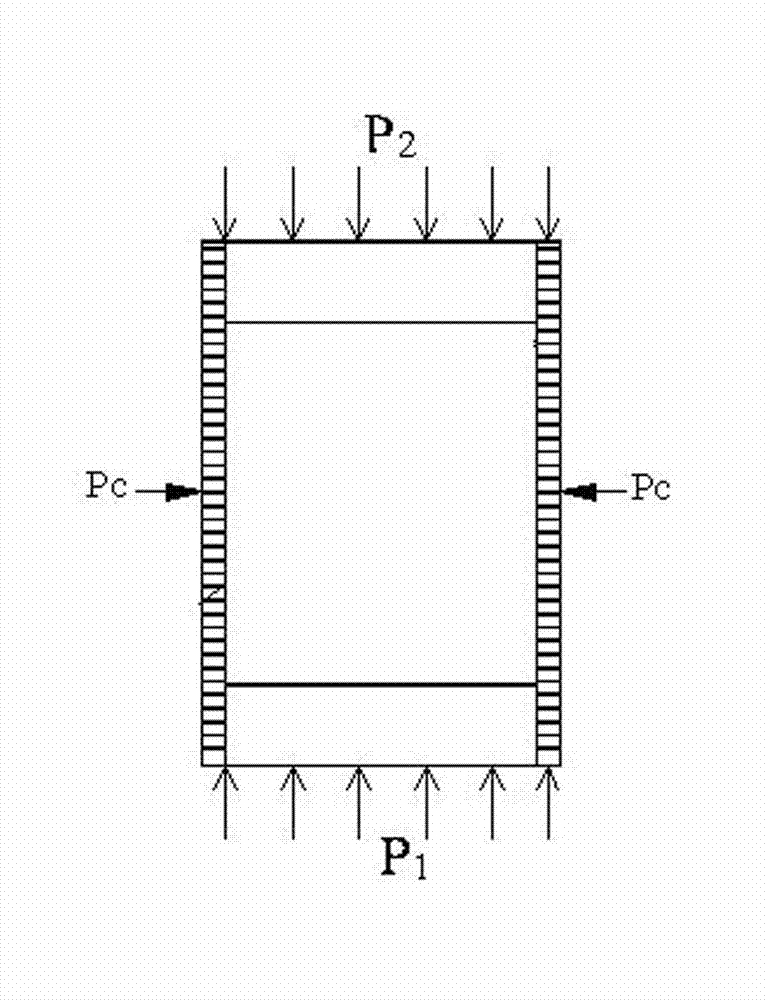

[0032] Example 1: like figure 1 As shown, a tight rock material gas permeability test device includes a pressure chamber 1, an air pressure loading system and a confining pressure loading system 2; a tight rock 3 to be tested is placed in the pressure chamber 1, and the tight rock 3 to be tested The surrounding area of the compact rock 3 is loaded with confining pressure through the confining pressure loading system 2, and the two ends of the tight rock 3 to be tested are loaded with air pressure through the air pressure loading system.

[0033] The air pressure loading system includes an inert gas source 4, an upper pressure gas storage tank 5, a lower pressure gas storage tank 6 and an air pressure control device, and the inert gas gas source 4 is connected with the upper and lower pressure gas storage tanks through connecting pipelines 5, 6, conveying inert gas for the upper and lower pressure gas storage tanks 5, 6; the air pressure control device is respectively conne...

Embodiment 2

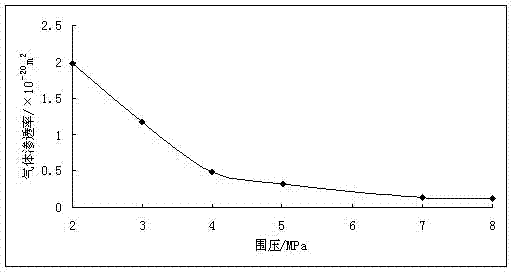

[0054] Example 2: The steps are the same as those in Example 1, except that: Step 1 selects different rock samples; Step 6 applies different pulse pressures; Step 4 applies greater confining pressure.

[0055] (1) Select Late Proterozoic granitic gneiss, process the rock sample into a cylindrical shape (see Table 3 for specific parameters), measure and record the diameter and height of the sample;

[0056] (2) Put the rock sample into the pressure chamber after being covered with high-performance rubber, and set porous metal backing plates at both ends of the rock sample, and adjust the position of the rock sample to make it balanced, so as to avoid the confining pressure not being fully effective due to uneven placement;

[0057] (3) Apply confining pressure P C When it reaches the predetermined value, close the valve of the confining pressure pump to stabilize the confining pressure at the predetermined value;

[0058] (4) Apply a small air pressure through the upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com