PLA/PBAT biodegradable composite material and product thereof

A composite material and biodegradable technology, which is applied in the field of PLA/PBAT biodegradable composite materials and its products, can solve the problems of poor impact resistance and tear resistance, and achieve high impact strength, good environmental benefits, and good toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

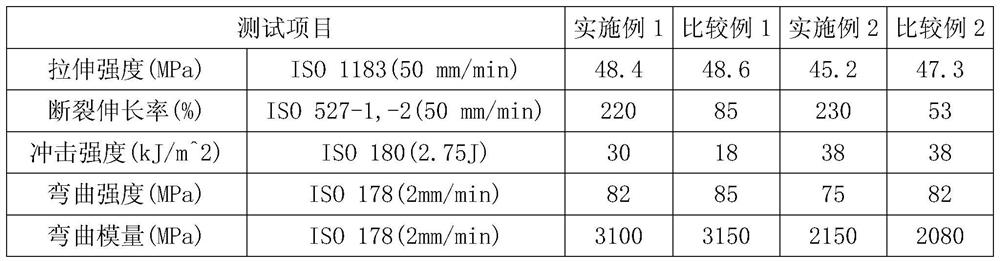

Embodiment 1

[0028] A PLA / PBAT biodegradable composite material, comprising 91.7 mass parts of polylactic acid (PLA), 5 mass parts of polybutylene adipate terephthalate (PBAT), 3 mass parts of polyethylene octene copolymer Graft maleic anhydride (POE-g-MAH) and 0.3 parts by mass of styrene-acrylate-epoxy acrylate copolymer.

[0029] Weigh the corresponding components according to the above proportions, mix and stir the components evenly, put them into a twin-screw extruder for melt blending, extrude and granulate, so as to obtain the PLA / PBAT biodegradable composite material.

Embodiment 2

[0034] A PLA / PBAT biodegradable composite material, comprising polylactic acid (PLA) of 63.7 mass parts, polybutylene adipate terephthalate (PBAT) of 30 mass parts, polyethylene octene copolymer of 3 mass parts Graft maleic anhydride (POE-g-MAH), 0.3 parts by mass of styrene-acrylate-epoxy acrylate copolymer and 3 parts by mass of talc.

[0035] Weigh the corresponding components according to the above proportions, mix and stir the components evenly, put them into a twin-screw extruder for melt blending, extrude and granulate, so as to obtain the PLA / PBAT biodegradable composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com