Fuel oil compositions with improved cold flow properties

a technology of cold flow and composition, applied in the direction of lubricant composition, liquid carbonaceous fuel, fuel, etc., can solve the problems of clogging of fuel filters in tanks and motor vehicles, including other fuel constituents, etc., and achieve the effect of improving performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 23

Preparative Examples 1 to 23

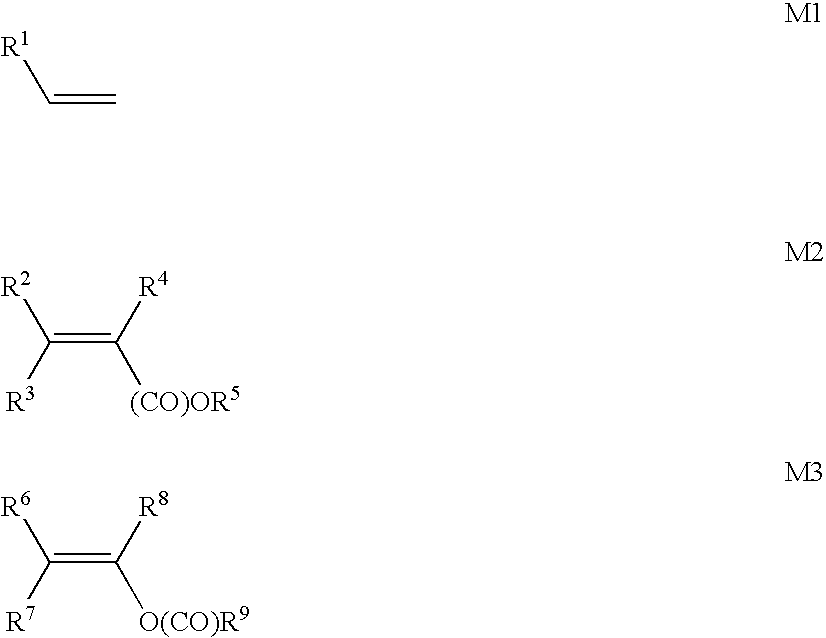

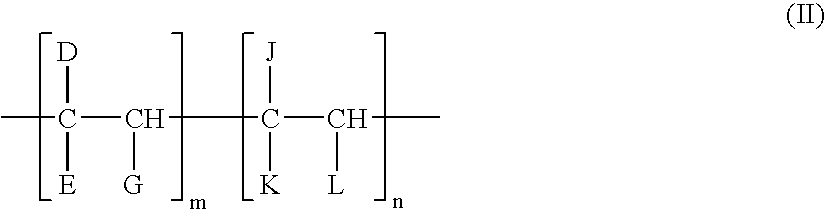

[0136] A total of 23 different inventive polymers were prepared by high-pressure polymerization of ethylene, 2-ethylhexyl acrylate (EHA) and vinyl acetate (VAC).

[0137] Table 1 compares the properties of the polymers used in the test examples which follow.

[0138] The content of ethylene, EHA and VAC in the resulting polymers was determined by NMR spectroscopy. The viscosities were determined to Ubbelohde DIN 51562.

TABLE 1PolymerEVACEHAViscosityNo.[Mol %][Mol %][Mol %][mm2 / s]MnMwMw / Mn188.04.27.860208841892.01288.04.47.6150295966662.25388.14.47.56054635128112.76486.63.99.560212442852.02586.44.39.3150302267542.23686.44.19.55954797132382.76783.84.112.160206442802.07883.24.412.4150299472032.41983.14.412.56004744145033.061080.24.515.3150303872792.401180.44.115.56004681156973.351289.68.02.460197739101.981389.87.92.3150283162122.191489.28.22.66053862110982.871589.88.44.860192839022.021686.58.45.1150292663372.171786.38.55.26204613120192.611884.28.17.760200340252...

example a

[0153] Middle distillate used: LGO, The Netherlands, CP=1.7° C., CFPP=−1° C., 25% n-paraffins, 90−20=70° C.

[0154] Dosage of the additives: 1500 ppm

TABLE 5AdditiveCFPP [° C.]Polymer No. 2−15Polymer No. 3−15Polymer No. 6−15Polymer No. 13−14Polymer No. 16−13Polymer No. 17−16Comparative product A−7Comparative product B−10Comparative product C−6Comparative product D−10

example b

[0155] Middle distillate used: diesel, Belgium, CP=−17° C., CFPP=−19° C., 19% n-paraffins, 90−20=89° C.

[0156] Dosage of the additives: 300 ppm

TABLE 6AdditiveCFPP [° C.]Polymer No. 5−25Polymer No. 16−25Comparative product A−23Comparative product B−23Comparative product C−24Comparative product D−23

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com