Aperture-controllable micro-porous membrane and making method thereof

A technology of microporous membrane and pore size, which is applied in the field of microporous membrane with controllable pore size and its preparation, can solve the problems of difficulty in actual machine production, poor reproducibility, complicated production process, etc., and achieve the effect of excellent waterproof and moisture permeability effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

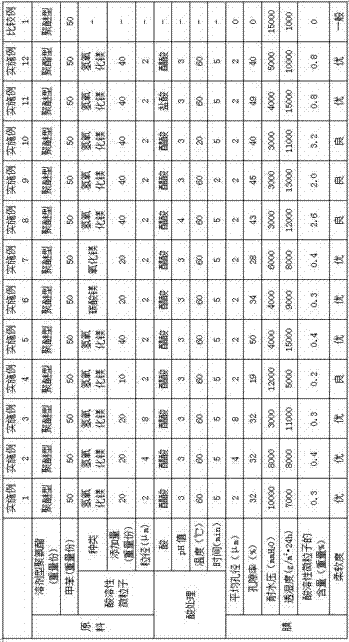

Examples

preparation example Construction

[0016] The preparation method of the microporous membrane with controllable pore size of the present invention comprises the following steps:

[0017] (1) Prepare coating resin processing fluid, at least including the following components:

[0018] 100 parts by weight of solvent-based polyurethane resin

[0019] Acid-soluble fine particles 5-60 parts by weight

[0020] The particle size of the acid-soluble microparticles used is 0.5-20 μm;

[0021] (2) Then apply the above-mentioned coating resin processing liquid to the surface of the release cloth or release paper to prepare a non-porous polyurethane resin film;

[0022] (3) Then put the above-mentioned non-porous polyurethane resin film into an acid aqueous solution for acid treatment;

[0023] (4) Finally wash with water to get the product.

[0024] Different types of acids may affect the stripping effect of acid-soluble microparticles. The acid used for acid treatment is preferably one of hydrochloric acid, nitric aci...

Embodiment 1

[0042] (1) Preparation of coating resin processing fluid:

[0043] 100 parts by weight of solvent-based polyether polyurethane resin

[0044] Magnesium hydroxide microparticles (2um) 20 parts by weight

[0045] 50 parts by weight of toluene

[0046] First, magnesium hydroxide is uniformly dispersed in toluene to obtain a mixed solution, and then the mixed solution is uniformly mixed with a solvent-based ether-type polyurethane resin to obtain a coating resin processing fluid;

[0047] (2) Next, on the coating machine, apply the above-mentioned coating resin processing fluid to the surface of the release cloth, and then dry it in a continuous drying oven (90°C → 130°C → 160°C) to form a film to obtain a 20μm-thick film. Porous polyether polyurethane resin film;

[0048] (3) Then, in the acid treatment tank, put the non-porous polyether polyurethane resin film prepared above into an aqueous acetic acid solution with a pH value of 3 for acid treatment at a temperature of 60°C ...

Embodiment 2

[0051] The particle size of the magnesium hydroxide microparticles used was 4 μm, and the rest were the same as in Example 1 to prepare a microporous resin film, the properties of which are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com