Preparation method of waterproof, moisture-permeable and temperature-adjustable intelligent nanofiber membrane

A nanofiber membrane, waterproof and moisture-permeable technology, applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve problems such as leakage, latent heat, low subcooling, hindering applications, etc., and achieve simple preparation process and relatively Moderate latent heat and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

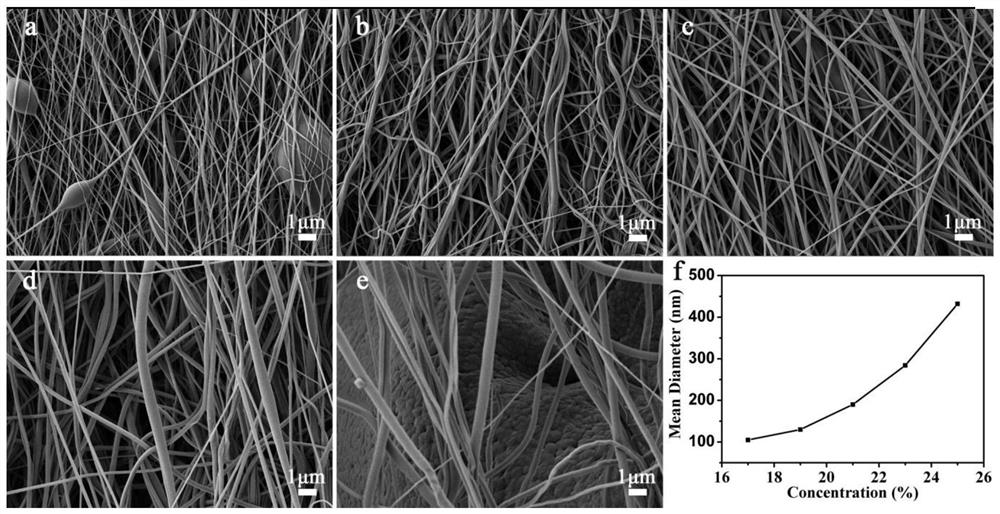

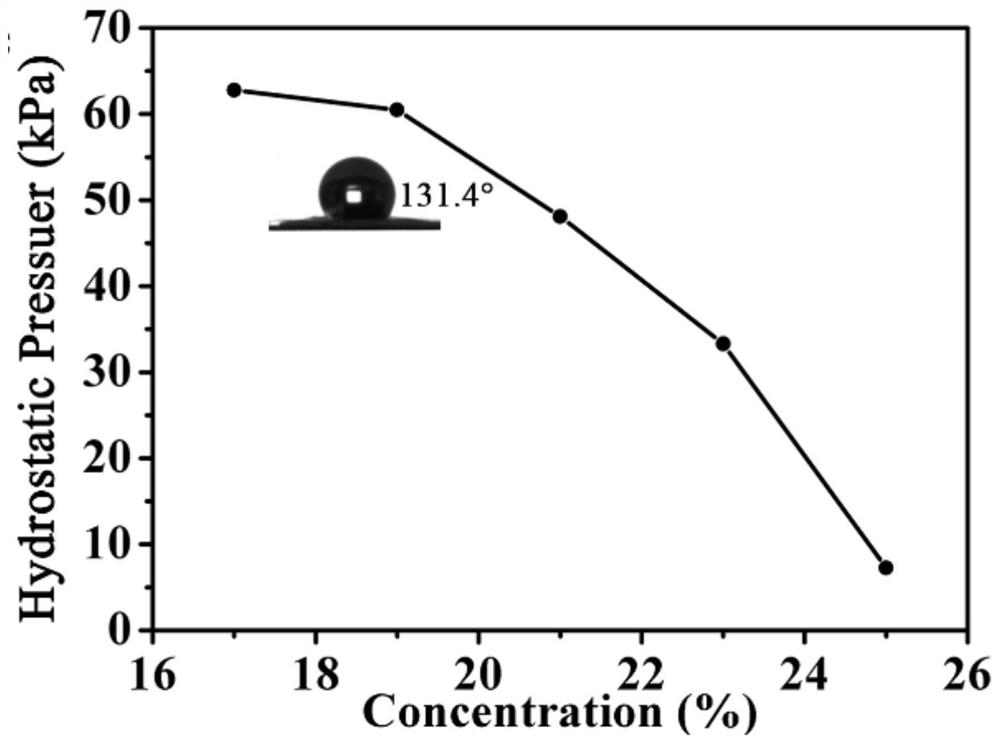

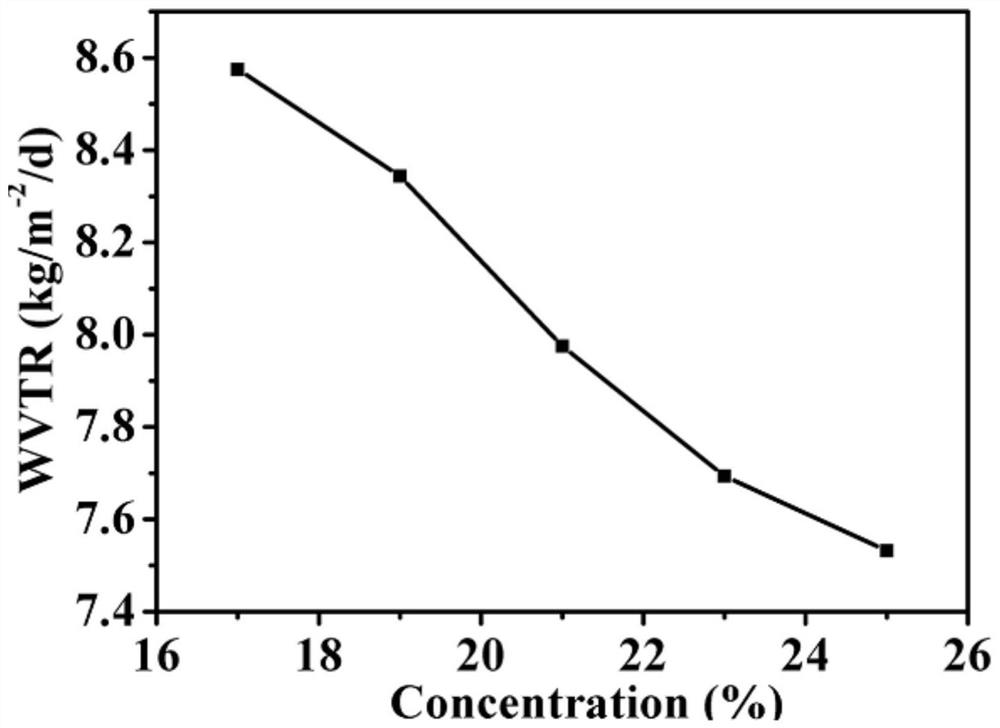

[0036] Take 0.003 g of sodium chloride and 0.15 g of carbon nanotubes and put them into a mixture of 8.0235 g of N,N-dimethylacetamide and 8.0235 g of acetone, then sonicate for 2 hours, then weigh 3.04 g of polyvinylidene fluoride and 0.76 g of polyvinyl butyral was put into the above solution, and stirred in a water bath at 50° C. for 24 hours with a magnetic stirrer until uniformly mixed to obtain a shell solution. Take 1.2 g of octadecane and put it into 2.8 g of kerosene, and mix well to obtain the core layer solution. Control the ambient temperature at 40°C, move the shell solution and the core layer into the needle tube of a 10 mL syringe, fix the syringe on the injector, connect the needle tube to the coaxial needle, and connect the coaxial needle to the high-voltage DC power supply The positive electrode is connected, the receiving drum wrapped in aluminum foil is connected to the negative electrode connected to the high-voltage DC power supply, the distance between t...

Embodiment 2

[0038] Put 0.003 g of sodium chloride and 0.1 g of carbon nanotubes into a mixture of 8.0485 g of N,N-dimethylacetamide and 8.0485 g of acetone, and then ultrasonicated for 2 hours, then weighed 3.04 g of polyvinylidene fluoride and 0.76 g of polyvinyl butyral was put into the above solution, and stirred in a water bath at 50° C. for 24 hours with a magnetic stirrer until uniformly mixed to obtain a shell solution. Take 1.2 g of octadecane and put it into 2.8 g of kerosene, and mix well to obtain the core layer solution. Control the ambient temperature at 40°C, move the shell solution and the core layer into the needle tube of a 10 mL syringe, fix the syringe on the injector, connect the needle tube to the coaxial needle, and connect the coaxial needle to the high-voltage DC power supply The positive electrode is connected, the receiving drum wrapped in aluminum foil is connected to the negative electrode connected to the high-voltage DC power supply, the distance between the ...

Embodiment 3

[0040]Take 0.003 g of sodium chloride and 0.05 g of carbon nanotubes and put them into a mixture of 8.0735 g of N,N-dimethylacetamide and 8.0735 g of acetone, then sonicate for 2 hours, then weigh 3.04 g of polyvinylidene fluoride and 0.76 g of polyvinyl butyral was put into the above solution, and stirred in a water bath at 50° C. for 24 hours with a magnetic stirrer until uniformly mixed to obtain a shell solution. Take 1.2 g of octadecane and put it into 2.8 g of kerosene, and mix well to obtain the core layer solution. Control the ambient temperature at 40°C, move the shell solution and the core layer into the needle tube of a 10 mL syringe, fix the syringe on the injector, connect the needle tube to the coaxial needle, and connect the coaxial needle to the high-voltage DC power supply The positive electrode is connected, the receiving drum wrapped in aluminum foil is connected to the negative electrode connected to the high-voltage DC power supply, the distance between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydrostatic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com