Preparation method of water-based high-performance waterproof and moisture permeable coated fabric

A coated fabric, waterproof and moisture-permeable technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor moisture permeability, low moisture permeability, poor waterproof ability, etc., and achieve low cost, short production process, The effect of saving cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

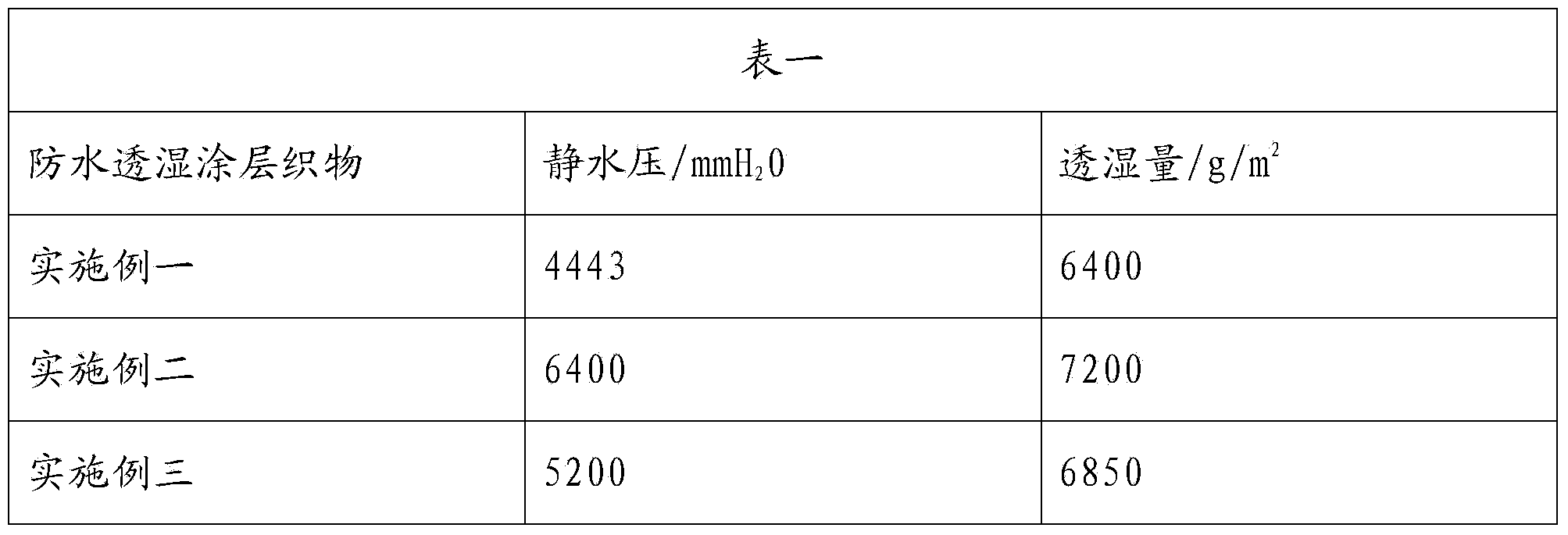

Embodiment 1

[0026] A method for preparing a water-based high-performance waterproof and moisture-permeable coated fabric:

[0027] (1) Preparation of primer adhesive: 88 parts by weight of water-based polyurethane, 8 parts by weight of water-based pore-forming agent, 2 parts by weight of water-based foam stabilizer, 1 part by weight of water-based cross-linking agent and 1 part by weight of Thickening agent, using a shear mixer to stir for 10 minutes, and then mechanically foaming to form a micro-nanoporous coating adhesive with a foam ratio of 1:4, that is, the primer adhesive; water-based polyurethane is a water-based polyurethane microdispersion, a water-based pore-forming agent , water-based foam stabilizer and water-based cross-linking agent are water-soluble;

[0028] (2) Preparation of surface coating adhesive: 88 parts by weight of polyacrylate aqueous emulsion, 8 parts by weight of water-based pore-forming agent, 2 parts by weight of water-based foam stabilizer, 1 part by weight ...

Embodiment 2

[0031] A method for preparing a water-based high-performance waterproof and moisture-permeable coated fabric:

[0032] (1) Preparation of primer adhesive: 93 parts by weight of water-based polyurethane, 5 parts by weight of water-based pore-forming agent, 1 part by weight of water-based foam stabilizer, 1 part by weight of water-based cross-linking agent and 1 part by weight of Thickener, use a shear mixer to stir for 30 minutes, and then mechanically foam to form a micro-nanoporous coating adhesive with a foam ratio of 1:2, that is, the primer adhesive; water-based polyurethane is a water-based polyurethane microdispersion, and water-based pore-forming Agent, water-based foam stabilizer and water-based crosslinking agent are all water-soluble;

[0033] (2) Preparation of surface coating adhesive: 93 parts by weight of polyacrylate aqueous emulsion, 5 parts by weight of water-based pore-forming agent, 1 part by weight of water-based foam stabilizer, 1 part by weight of water-b...

Embodiment 3

[0036] A method for preparing a water-based high-performance waterproof and moisture-permeable coated fabric:

[0037] (1) Preparation of primer adhesive: 90 parts by weight of water-based polyurethane, 6 parts by weight of water-based pore-forming agent, 2 parts by weight of water-based foam stabilizer, 2 parts by weight of water-based cross-linking agent and 2 parts by weight of Thickener, use a shear mixer to stir for 30 minutes, and then mechanically foam to form a micro-nanoporous coating adhesive with a foam ratio of 1:6, that is, the primer adhesive; water-based polyurethane is a water-based polyurethane microdispersion, and water-based pore-forming Agent, water-based foam stabilizer and water-based crosslinking agent are all water-soluble;

[0038](2) Preparation of surface coating adhesive: 90 parts by weight of polyacrylate aqueous emulsion, 6 parts by weight of water-based pore-forming agent, 2 parts by weight of water-based foam stabilizer, 2 parts by weight of wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com