Terylene elastic fabric

A technology of elastic fabric and polyester, which is applied in the field of polyester weft elastic fabric, can solve the problems of complex fiber dyeing process, etc., and achieve the effect of superior waterproof and moisture-permeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

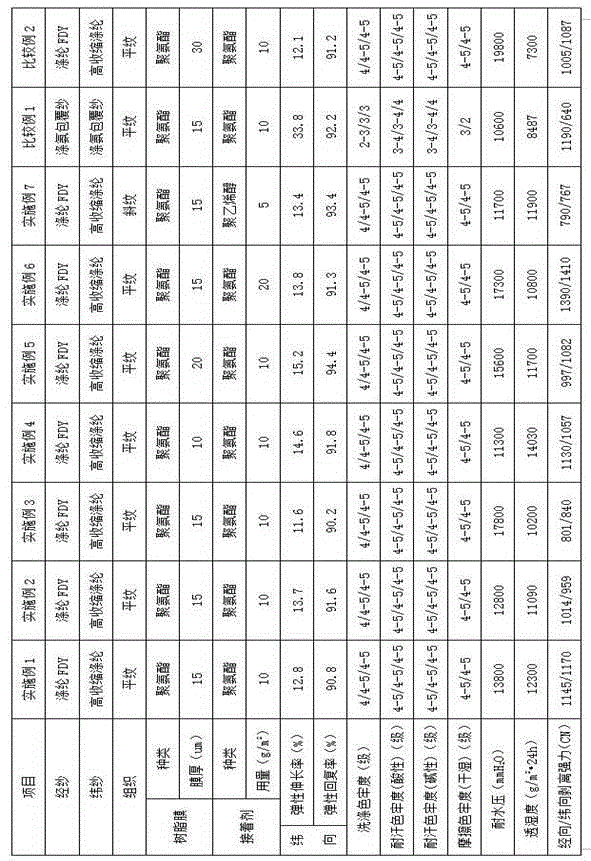

Examples

Embodiment 1

[0034] Use 50D-48f-polyester FDY yarn for the warp yarn, 50D-48f-high shrinkage polyester DTY yarn for the weft yarn, and plain weave for weaving. Intermediate shaping→130℃×30min dyeing→guiding drying→170℃ shaping→160℃ calendering→water-repellent finishing to obtain the base fabric, and finally attach the 15μm polyurethane hydrophilic film to the calendering of the obtained base fabric with polyurethane adhesive On smooth surface, the dosage of adhesive is 10g / m 2 , to obtain the product, the specific properties are shown in Table 1.

[0035] For refining, the temperature is 90°C, the speed is 50m / min, using hot alkali? Refining agent? Wrap the outer layer of the roll with a layer of plastic film and stack it for 8 hours; set it in the middle with a temperature of 180°C, a speed of 50m / min, and a wind speed of 30Hz, and the method of dropping the cloth by vibration; guide the net to dry at a temperature of 130°C and a speed of 50m / min , Falling cloth is the way of vibration....

Embodiment 2

[0037] On the surface of the polyurethane film of the gained polyester elastic fabric, the grid dot pattern was printed, and all the other were the same as in Example 1 to obtain the product, and the specific properties were shown in Table 1.

Embodiment 3

[0039] Lay polar fleece or brushed cloth or brushed cloth on the other side (non-membrane side) of the obtained polyester elastic fabric, and the amount of adhesive is 15g / m 2 , all the other are with embodiment 1, obtain product, and concrete performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com