Waterproof and moisture-permeable coiled material with three-dimensional structure, production method and wall structure

A waterproof, moisture-permeable, three-dimensional structure technology, applied in chemical instruments and methods, building components, layered products, etc., can solve the problems of high labor cost and material cost, and troublesome construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

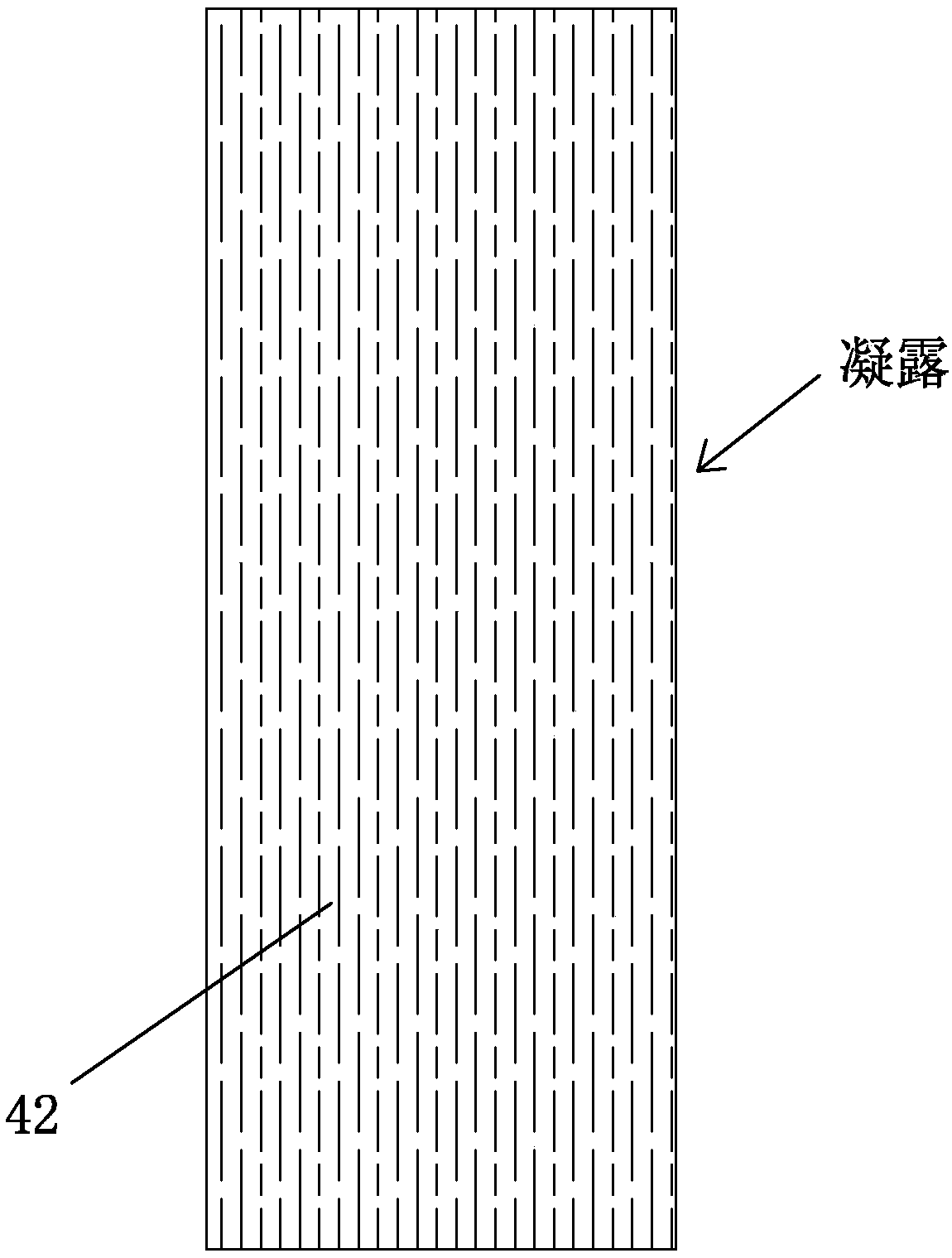

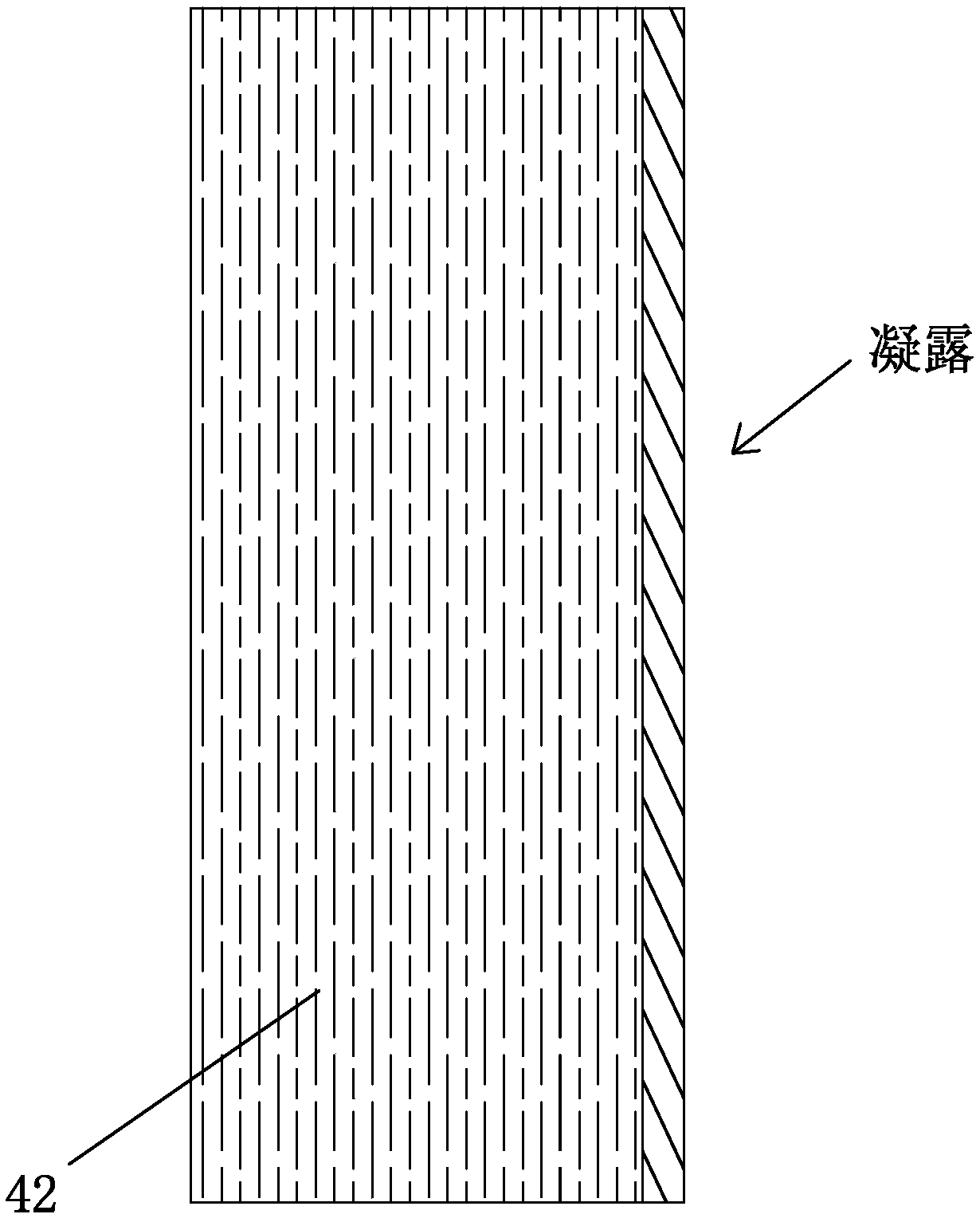

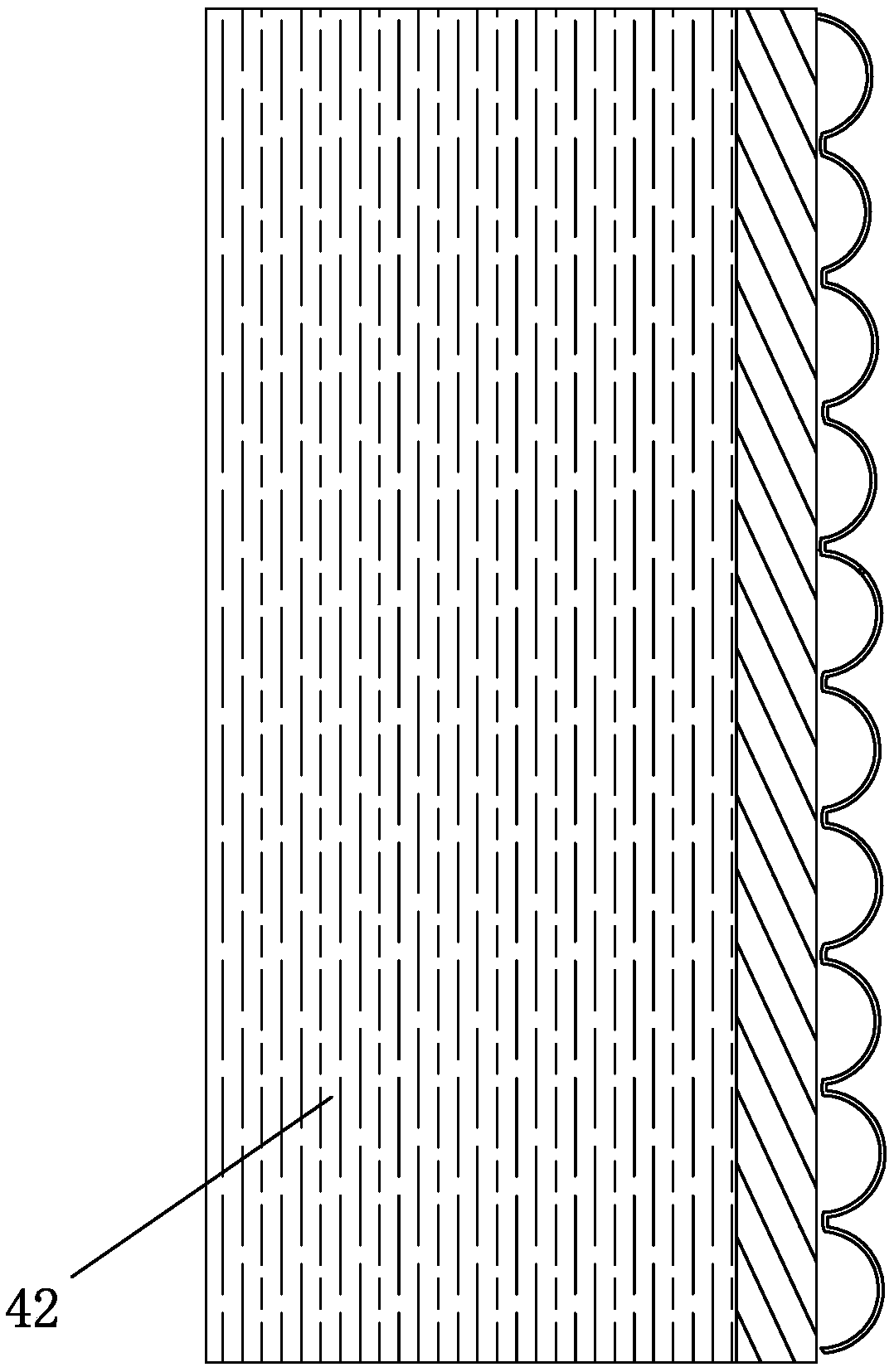

[0088] A waterproof and moisture-permeable membrane with a three-dimensional structure, such as Figure 4 As shown, from top to bottom, it includes a waterproof and moisture-permeable coil 1 and a gap layer 2 (forming an air duct in the waterproof and moisture-permeable wall structure), wherein the waterproof and moisture-permeable coil 1 includes three layers: the first non-woven layer 11. The waterproof and moisture-permeable functional layer 12 and the second non-woven layer 13; the thickness ratio of the first non-woven layer 11, the waterproof and moisture-permeable functional layer 12 and the second non-woven layer 13 is 5:2:3, which is waterproof The moisture-permeable functional layer 12 can be made of materials such as PE or TPU, such as Image 6 As shown, the gap layer 2 is composed of several elastic protrusions 21, and the structure of the elastic protrusions 21 is as follows Figure 5 As shown, the elastic protrusions 21 are made of plastic material with certain ...

Embodiment 2

[0091] A production method of a waterproof and moisture-permeable coiled material with a three-dimensional structure mainly comprises the following steps:

[0092] Stp1: Fix the waterproof and moisture-permeable membrane 1, and the surface is flat;

[0093] Stp2: heating the elastic protrusions 21 to be viscous. In this embodiment, the heating method is adopted, and the heating method can be hot blanching, thermal radiation heating or sonic heating;

[0094] Stp3: Adhere the elastic protrusions 21 processed in Stp2 to the surface of the first waterproof head layer 1 to form a complete waterproof and moisture-permeable roll material with a three-dimensional structure.

[0095] The waterproof and moisture-permeable membrane with a three-dimensional structure prepared here is the waterproof and moisture-permeable membrane shown in Example 1.

Embodiment 3

[0097] A production method of a waterproof and moisture-permeable coiled material with a three-dimensional structure mainly comprises the following steps:

[0098] Stp1: Fix the waterproof and moisture-permeable membrane 1, and the surface is flat;

[0099] Stp2: Fix the elastic protrusions 21 on the surface of the first non-woven fabric layer 11 by laser welding to form a complete waterproof and moisture-permeable roll material with a three-dimensional structure.

[0100] The waterproof and moisture-permeable roll material with a three-dimensional structure prepared here is the waterproof and moisture-permeable roll material with a three-dimensional structure shown in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com